Speed-increase type concurrent flow rotating spraying type gas washing tower

A technology of gas scrubbing and rotary spraying, applied in the field of gas scrubbers, which can solve the problems of insufficient reaction of scrubbers, high moisture content in gas discharge, large tower structure size, etc., to avoid droplet escape, good effect, Addressing Underresponsive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

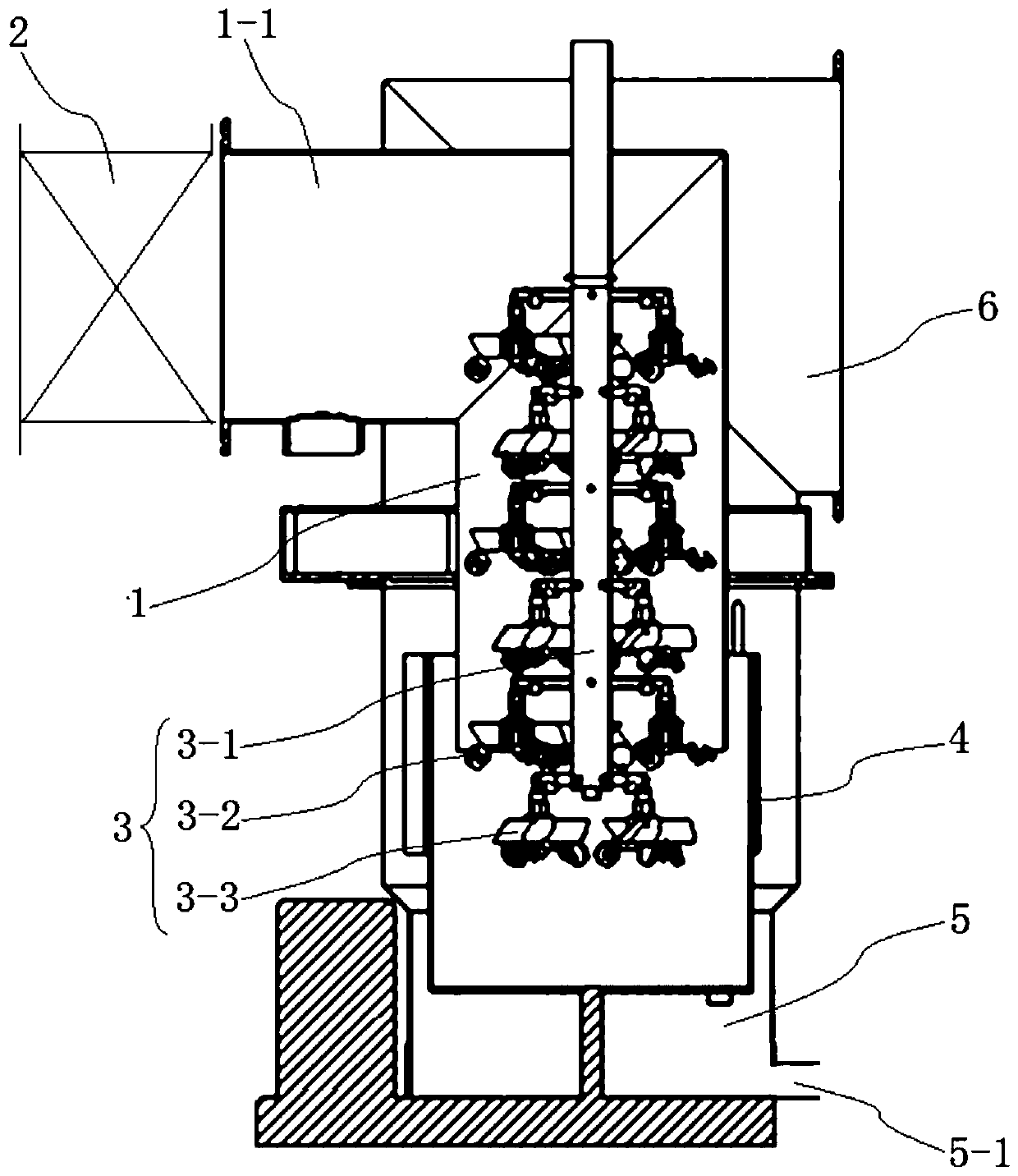

[0034] combine figure 1As shown, a speed-increasing type downstream rotary spraying gas scrubber of this embodiment includes a vertically arranged air inlet duct 1, an induced draft fan 2 capable of inducing wind into the air inlet duct 1, and the existing The difference with the gas scrubber is that the air introduced by the induced draft fan 2 into the air inlet duct 1 is blown from top to bottom, and the air inlet duct 1 is equipped with a rotary spraying mechanism 3 for atomizing and rotating spraying. The blowing direction of the gas is the same as the water flow direction of the rotary spray mechanism 3, which reduces the gas flow resistance and improves the gas flow velocity. Under the premise of not increasing the wind resistance, other means are introduced to improve the atomization of liquid particles and gas fluids. The contact opportunity creates conditions, using the rotary spray mechanism 3 for atomized spraying, which increases the degree of turbulence, strength...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com