An alkyl polyether co-modified polysiloxane and its continuous synthesis device and method

A technology of polysiloxane and alkyl polyether, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physicochemical processes, etc. Low efficiency and other problems, to achieve the effect of preventing flying temperature, less by-products, and strong heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

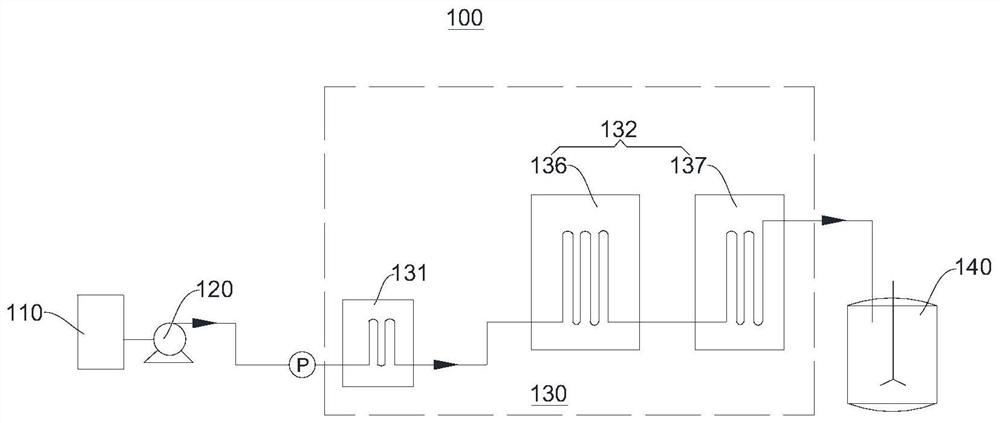

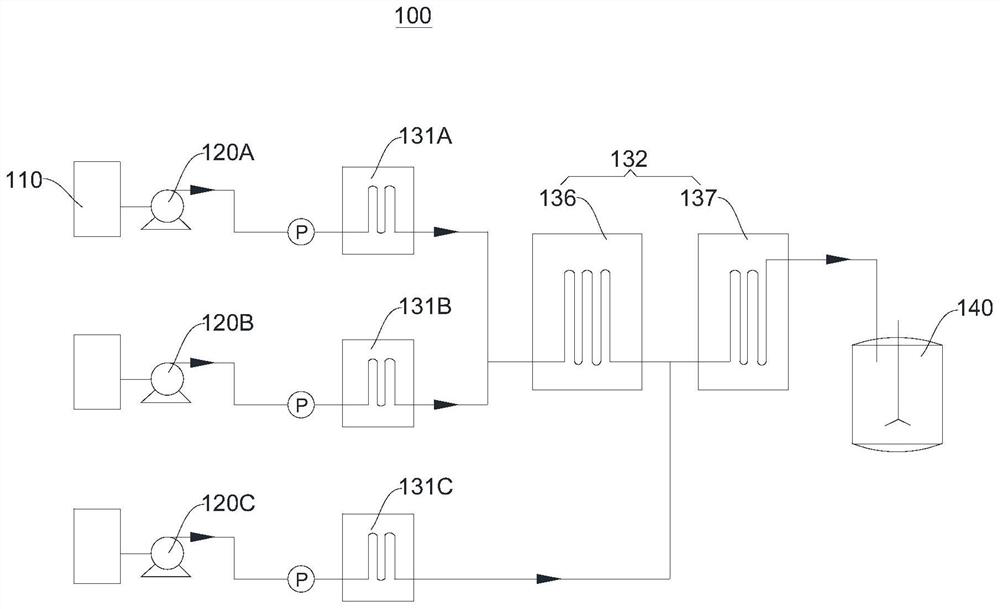

[0089] The application provides a method for continuous synthesis of polysiloxane co-modified by alkyl polyether, which adopts such as figure 2 The device 100 for the continuous synthesis of the polysiloxane co-modified by the alkyl polyether shown in the figure carries out the synthesis reaction, specifically:

[0090] (1) Add 281.52g of octamethylcyclotetrasiloxane, 138.75g of high hydrogen-containing silicone oil, 79.73g of hexamethyldisiloxane and 15g of acidic catalyst into a three-necked flask, heat up to 60°C, and wait for the temperature to stabilize Afterwards, heat-retain and react for 8 hours to obtain hydrogen-containing polysiloxane.

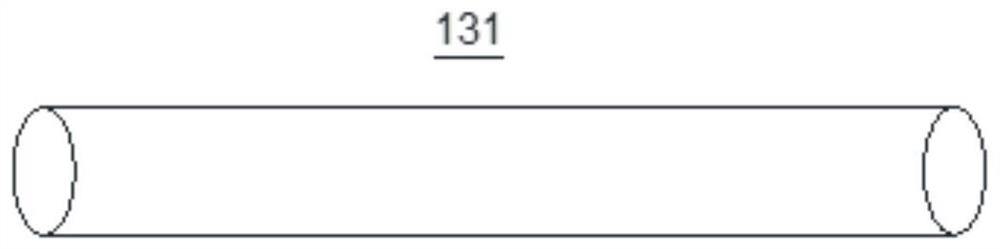

[0091] (2) With the microchannel system as the reactor, the channel structure is matched as (wherein, the structure of the preheating pipeline 131 is as follows image 3 As shown, the structure of the mixing pipeline 132 is as Figure 4 shown). Set the preheating temperature and reaction temperature to 110° C., and the reaction ...

Embodiment 2

[0093] The application provides a method for continuous synthesis of polysiloxane co-modified by alkyl polyether, which adopts such as figure 2 The device 100 for the continuous synthesis of the polysiloxane co-modified by the alkyl polyether shown in the figure carries out the synthesis reaction, specifically:

[0094] (1) Add 243.42g of octamethylcyclotetrasiloxane, 131.22g of high hydrogen-containing silicone oil, 125.36g of hexamethyldisiloxane and 20g of acidic catalyst into a three-necked flask, heat up to 60°C, and wait for the temperature to stabilize Afterwards, heat-retain and react for 8 hours to obtain hydrogen-containing polysiloxane.

[0095] (2) With the microchannel system as the reactor, the channel structure is matched as (wherein, the structure of the preheating pipeline 131 is as follows image 3 As shown, the structure of the mixing pipeline 132 is as Figure 5 shown). Set the preheating temperature and reaction temperature to 130° C., and the reaction...

Embodiment 3

[0099] The application provides a method for continuous synthesis of polysiloxane co-modified by alkyl polyether, which adopts such as figure 2 The device 100 for the continuous synthesis of the polysiloxane co-modified by the alkyl polyether shown in the figure carries out the synthesis reaction, specifically:

[0100] (1) Add 267.41g of octamethylcyclotetrasiloxane, 134.19g of high hydrogen-containing silicone oil, 98.4g of hexamethyldisiloxane and 16g of acidic catalyst into a three-necked flask, heat up to 60°C, and wait for the temperature to stabilize Afterwards, heat-retain and react for 8 hours to obtain hydrogen-containing polysiloxane.

[0101] (2) With the microchannel system as the reactor, the channel structure is matched as (wherein, the structure of the preheating pipeline 131 is as follows image 3 As shown, the structure of the mixing pipeline 132 is as Figure 6 shown). Set the preheating temperature and reaction temperature to 120° C., and the reaction p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com