A kind of preparation device and preparation method of high-purity chlorine dioxide

A chlorine dioxide preparation device technology, applied in the direction of chlorine dioxide, chlorine oxide, etc., can solve problems affecting the purity of chlorine dioxide, low purity of chlorine dioxide, lack of solutions, etc., to reduce raw material costs and improve redox Potential, the effect of improving product conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

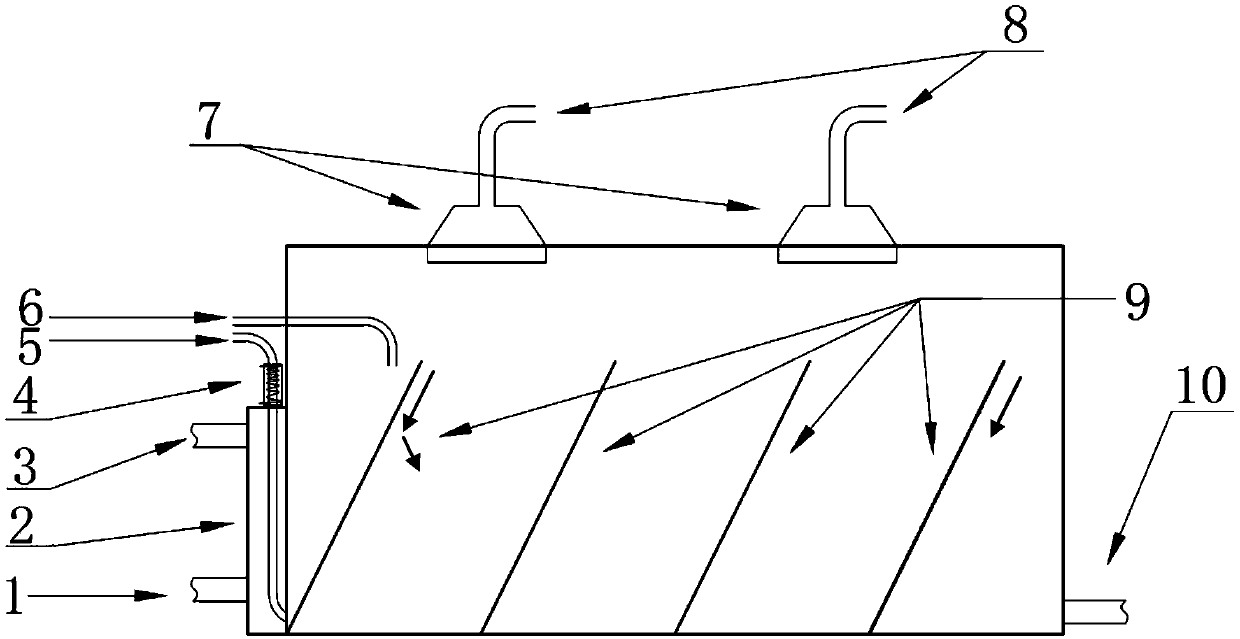

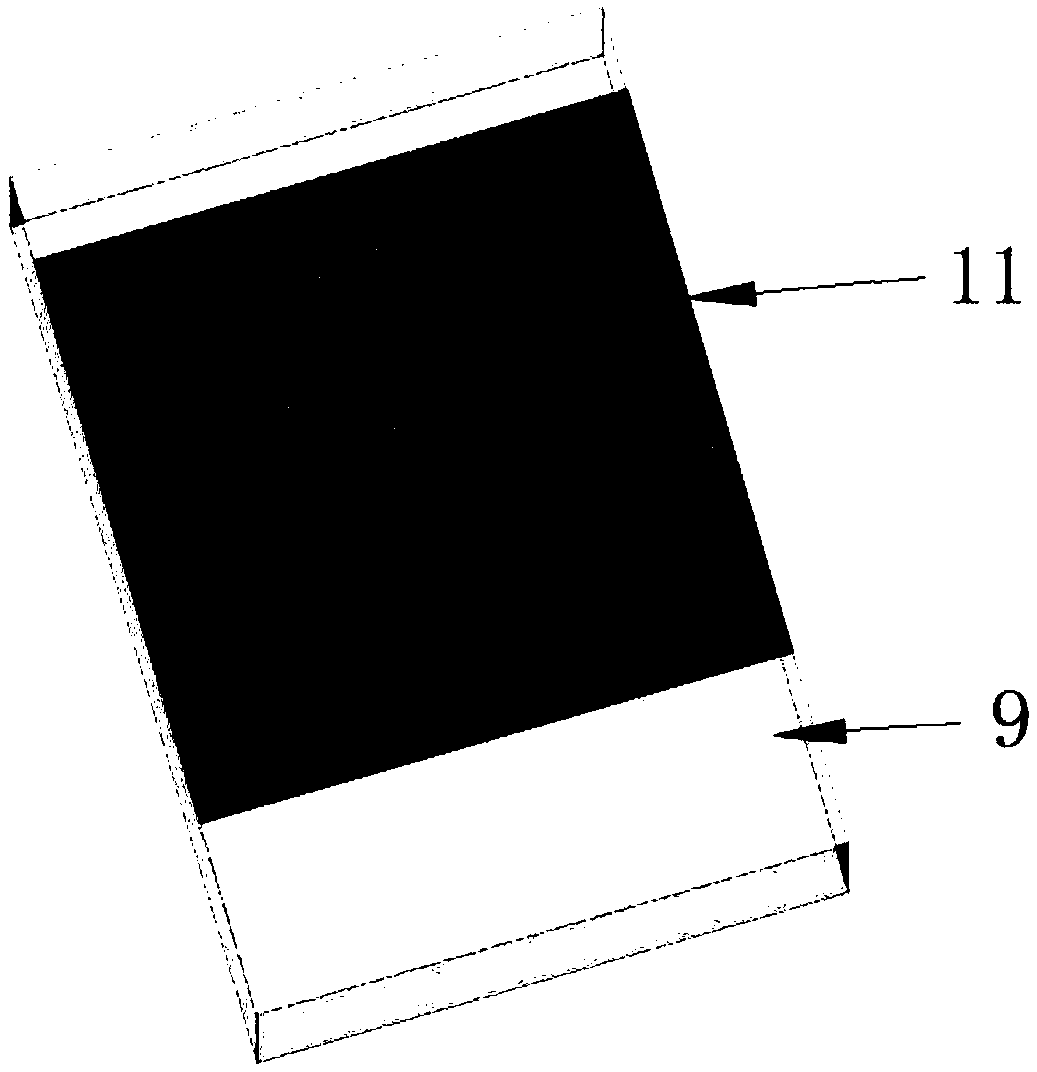

Embodiment 1

[0057] The volume ratio of the heating water tank 2 to the reaction box is 1:10, and the inclination angle between each inclined plate 9 and the horizontal direction is 68°. Enter medicine by following proportioning, sodium chlorate 35 weight parts, sucrose 5 weight parts, citric acid 2 weight parts, sulfuric acid 40 weight parts. Firstly sodium chlorate, sucrose, citric acid and water are made into compound sodium chlorate solution by 35:5:2:100, and sulfuric acid is made into dilute sulfuric acid with a mass fraction of 60%, with a total dosing speed of 7L / h into medicine. When the equipment is started, the feed temperature of the compound sodium chlorate solution is heated to 50°C, and after 30 minutes of feed, the temperature of the heating water tank 2 reaches about 55°C. Now the conversion rate of sodium chlorate is 95%, the output of chlorine dioxide is 2kg / h, and the purity of chlorine dioxide is 99%.

Embodiment 2

[0059] The volume ratio of the heating water tank 2 to the reaction box is 2:10, and the inclination angle between each inclined plate 9 and the horizontal direction is 70°. Enter medicine by following proportioning, sodium chlorate 25 weight parts, sucrose 8 weight parts, malic acid 5 weight parts, sulfuric acid 30 weight parts. Firstly sodium chlorate, sucrose, citric acid and water are made into compound sodium chlorate solution by 25:8:5:100, and sulfuric acid is made into dilute sulfuric acid with a mass fraction of 30%, with a total dosing speed of 8L / h into medicine. When the equipment is started, the feed temperature of the compound sodium chlorate solution is heated to 60°C, and after 30 minutes of feed, the temperature of the heating water tank 2 reaches about 65°C. Now the conversion rate of sodium chlorate is 97%, the output of chlorine dioxide is 2kg / h, and the purity of chlorine dioxide is 99.2%.

Embodiment 3

[0061] The volume ratio of the heating water tank 2 to the reaction box is 2:10, and the inclination angle between each inclined plate 9 and the horizontal direction is 72°. Enter medicine by following proportioning, sodium chlorate 10 weight parts, sucrose 5 weight parts, formic acid 2 weight parts, sulfuric acid 20 weight parts. First, sodium chlorate, sucrose, citric acid and water are made into a compound sodium chlorate solution at a ratio of 10:5:2:100, and sulfuric acid is made into dilute sulfuric acid with a mass fraction of 45%, with a total dosing speed of 8L / h into medicine. When the equipment is started, the feed temperature of the compound sodium chlorate solution is heated to 60°C, and after 30 minutes of feed, the temperature of the heating water tank 2 reaches about 62°C. Now the conversion rate of sodium chlorate is 94%, the output of chlorine dioxide is 1.9kg / h, and the purity of chlorine dioxide is 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com