Integrated ultrasonic field-assisted microchannel reactor for supercritical hydrothermal synthesis of nanomaterials

A microchannel reactor and microchannel reaction technology, applied in chemical/physical/physical-chemical reactors, chemical instruments and methods, chemical/physical/physical-chemical processes, etc. Easy to block and other problems, to achieve the effect of preventing agglomeration, moderate size, and avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

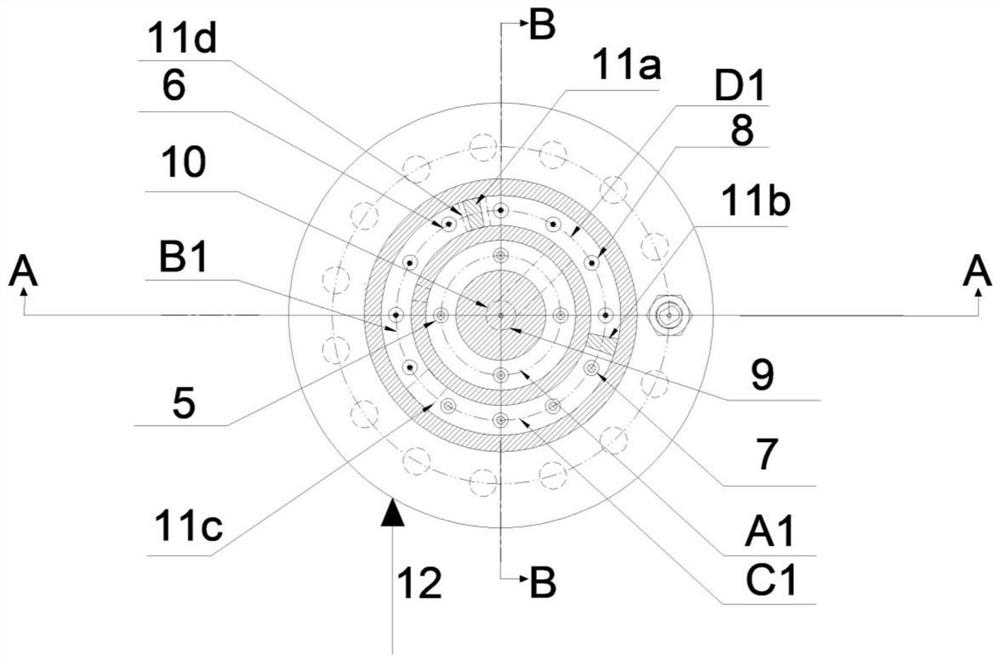

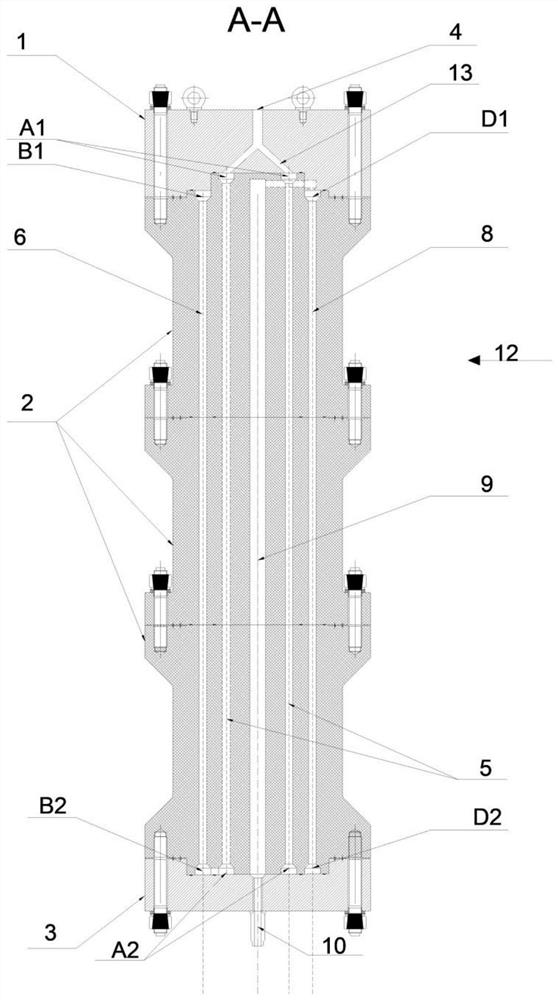

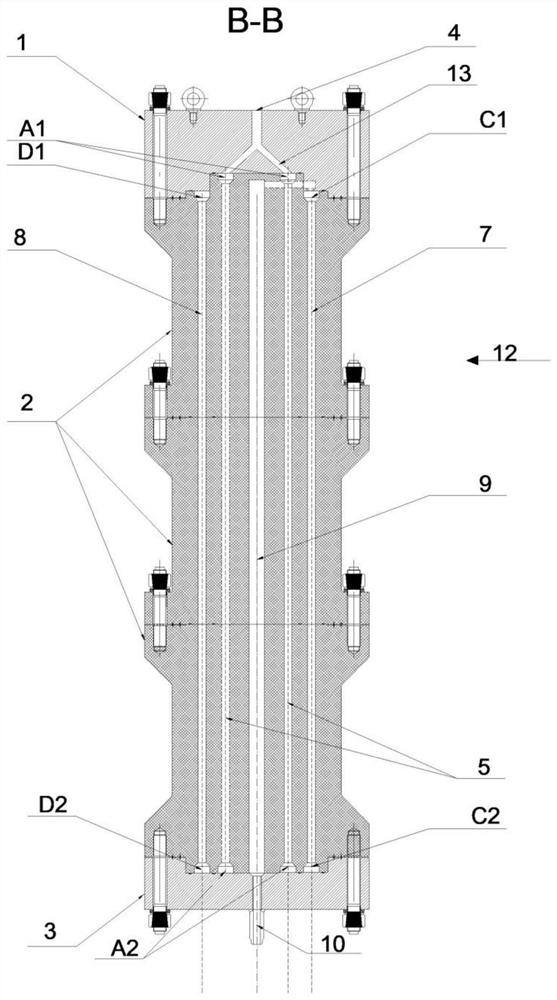

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings and examples.

[0034] like figure 1 , figure 2 and image 3 As shown in the figure, the present invention is an integrated ultrasonic external field-assisted microchannel reactor for supercritical hydrothermal synthesis of nanomaterials, comprising a main body 2, on the top and bottom of the main body 2, an upper end cap 1 and a lower end cap can be respectively configured 3. The material inflow channel 4 is arranged at the axis of the upper end cover 1 , and the product outlet 10 is arranged at the center of the lower end cover 3 . It should be noted, figure 1 middle It means that the fluid flows in perpendicular to the paper surface; "⊙" means that the fluid flows out perpendicular to the paper surface.

[0035]The main body 2 is composed of multiple supercritical microchannel reaction modules docked along the axial direction. Obviously, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com