A simple fertilizer grinder

A pulverizer and simple technology, which is applied in the field of simple fertilizer pulverizers, can solve the problems of pulverizer inner lining corrosion and impact, poor pulverizing effect of pulverizing device, cumbersome disassembly and replacement of lining, etc., to solve production costs, pulverize The effect of good effect, good promotion and use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

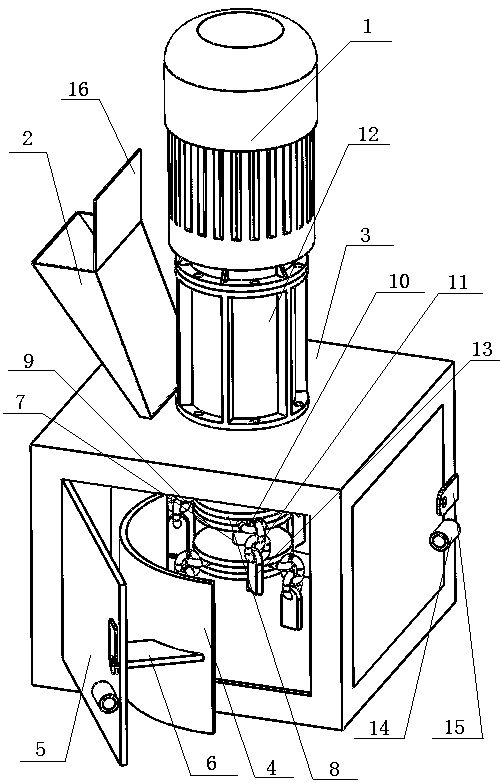

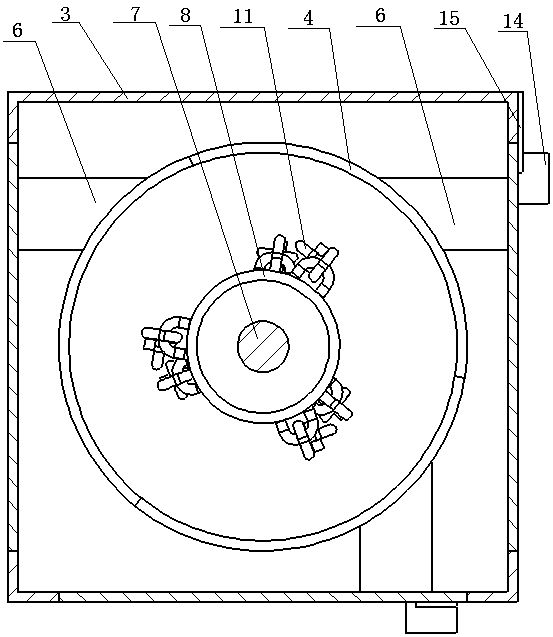

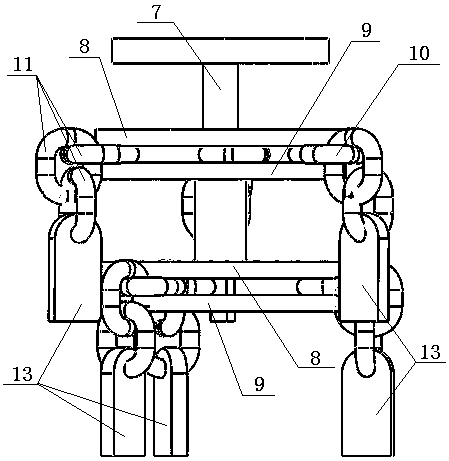

[0028] A kind of simple type fertilizer pulverizer of the present invention, its structure comprises driving motor 1, feeding hopper 2, pulverizer casing 3 and pulverizing device; A shaft coupling 12 is also arranged between the shredder casing 3, and the output shaft of the driving motor 1 is fixedly connected with the transmission shaft 7 in the pulverizing device through the coupling 12; the top of the shredder casing 3 is provided with a large upper end and a small lower end The feed hopper 2 of the trapezoidal structure, the top of the feed hopper 2 is also provided with a feed baffle 16 to prevent material from overflowing; the crushing device is arranged in the pulverizer casing 3, and the pulverizer casing 3 is installed on the pulverizer frame; The output shaft of the drive motor 1 is fixedly connected with the coaxial center of the crushing device, and the rotation of the output shaft of the drive motor 1 can drive the crushing device to rotate; the inside of the grin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com