Application method of loop slurry reactor adopting novel filtration module

A loop reactor and filter assembly technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of complex equipment structure, complicated equipment, complicated operation, etc., to improve separation efficiency, improve reaction performance, and save reactions. effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

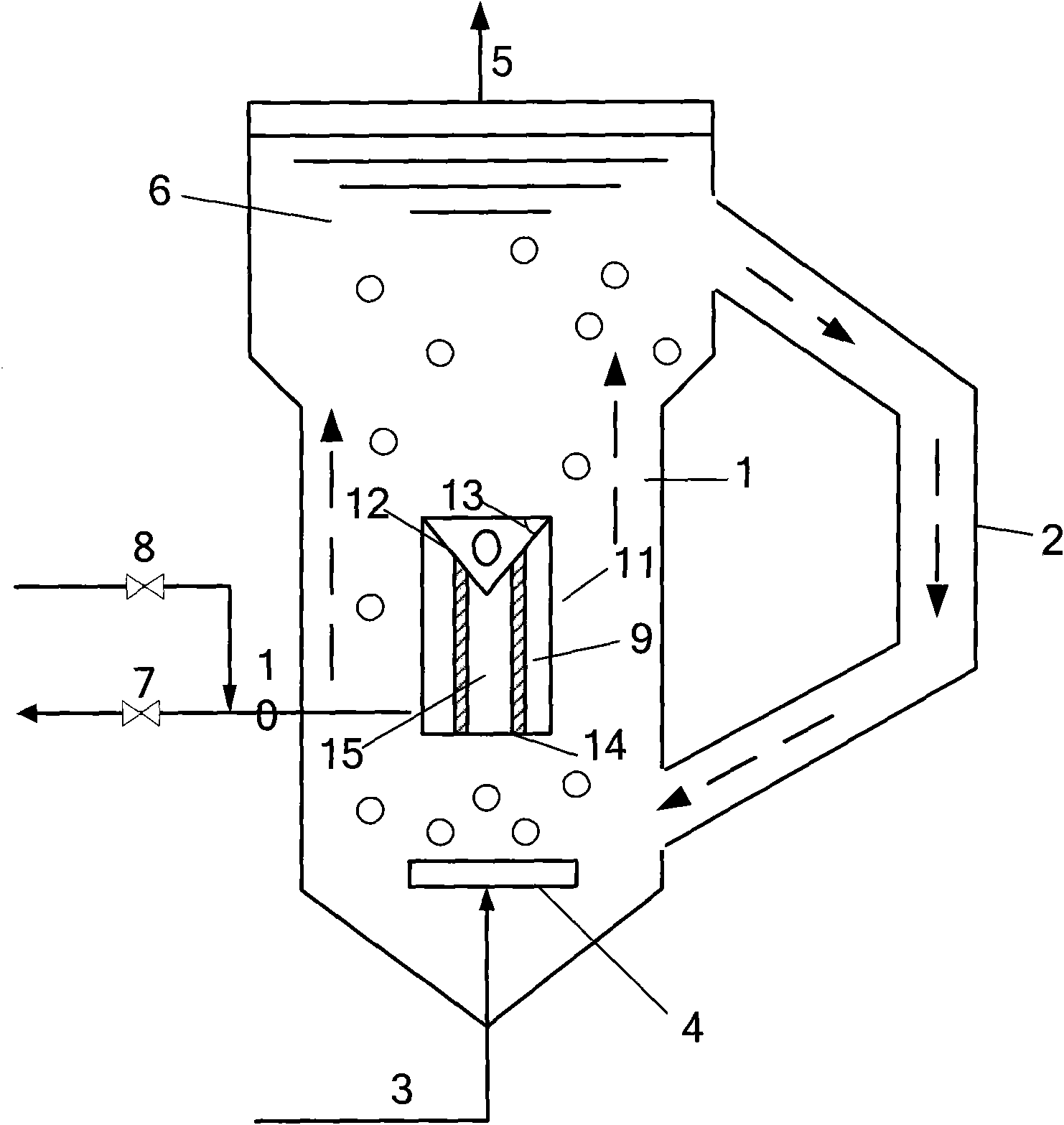

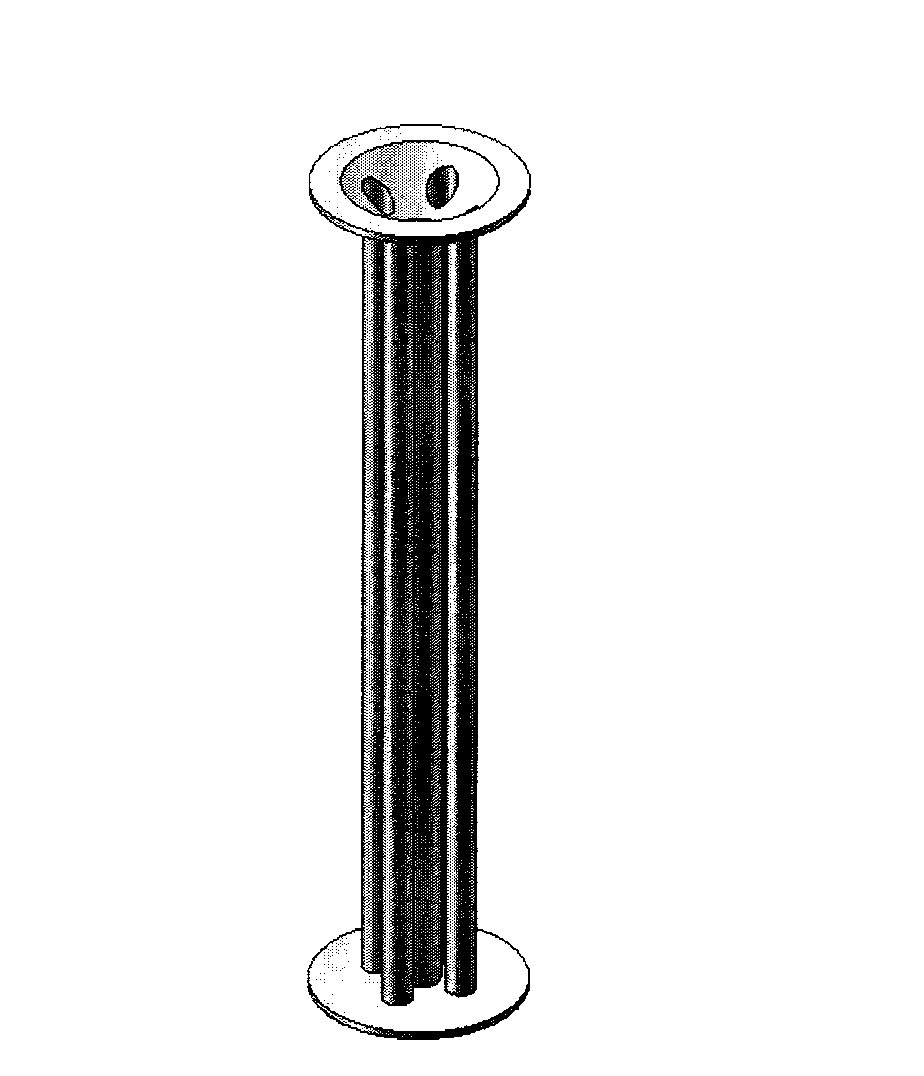

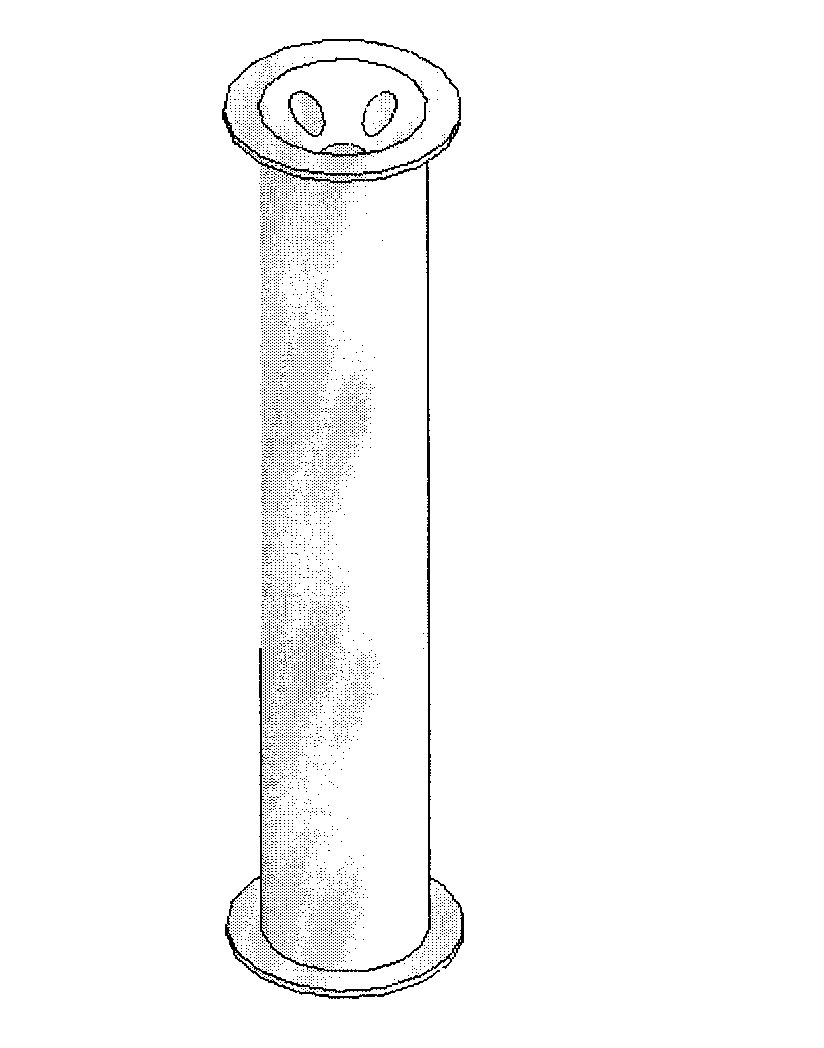

[0039] Attached figure 1 The slurry bed loop reactor shown, wherein the diameter ratio of the settling zone of the slurry bed loop reactor and the lower part of the riser is 1.5:1, the ratio of the diameter of the riser to the downcomer is 4:1, and the filter assembly The ratio to the diameter of the riser is 1:10. The internal structure of the filter assembly is attached figure 2 , the cone angle 13 of the upper isolation plate of the filter assembly is 45°. Each filter tube has a diameter of 50 mm and a length of 1000 mm. The filter tube is made of sintered porous metal filter tube with an average pore size of 1 μm. The catalyst used in the slurry zone 11 is an iron-based catalyst with a particle size ranging from 1 to 100 μm.

[0040] The synthesis gas is introduced from the gas inlet 3 at the bottom of the riser, and enters the reaction zone of the slurry bed reactor in the form of bubbles through the gas distributor 4. The synthesis gas is in contact with the solid ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com