Graphene inorganic coating with pearlescent effect and preparation method

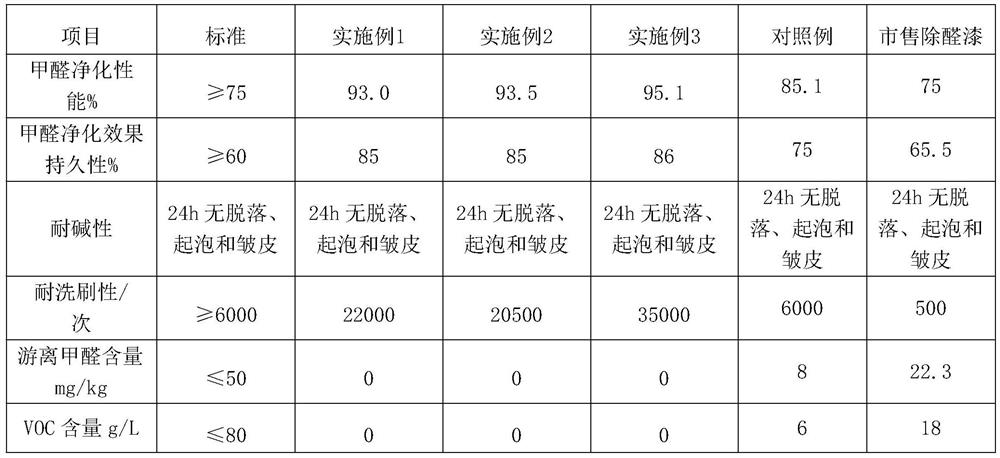

A technology for inorganic coatings and pearlescent effects, applied in the direction of alkali metal silicate coatings, coatings, etc., can solve the problems of formaldehyde purification effect durability and adhesion to be improved, difficult to achieve aldehyde removal effect, and short direct sunlight time , to achieve excellent aldehyde removal effect, good air permeability, and improve the effect of decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0033] The present invention adopts an embodiment of the present invention, including the following components in parts by mass: 10-30 parts of inorganic resin, 0.05-1 part of graphene-modified anti-formaldehyde additive, and 0.05-0.5 part of multi-functional additive , 10-40 parts of deionized water, 5-8 parts of polymer emulsion, 0.05-0.5 parts of defoamer, 0.05-1 part of dispersant, 0.05-1 part of rheological additive, 0.1-0.5 part of thickening aid, 30-50 parts of pigments and fillers, 10-20 parts of pearl paste;

[0034] Among them, the inorganic resin is used to replace the existing commonly used polymer emulsion for the graphene modified anti-formaldehyde additive. The inner diameter of the inorganic resin is less than 5 microns, which is smaller than the particle size of the conventional polymer emulsion, so that the inorganic resin particles can effectively enter the bottom of the wall. In the material, the adhesion between the paint and the painted surface is improve...

Embodiment 1

[0040] One embodiment of the present invention comprises the following components in parts by mass: 10 parts of inorganic resins, 0.3 parts of graphene-modified anti-formaldehyde additives, 0.1 parts of multifunctional additives, 27.5 parts of deionized water, polymer 5 parts of emulsion, 0.2 parts of defoamer, 0.3 parts of dispersant, 1 part of rheological additive, 0.3 part of thickening additive, 45 parts of pigments and fillers (15 parts of titanium dioxide, 15 parts of kaolin, 15 parts of barium sulfate), pearlescent 10 parts of powder paste;

[0041] Among them, the graphene-modified anti-formaldehyde auxiliary agent is prepared as follows: the sheet-layer graphene with a single-layer rate greater than 75% is ultrasonically dispersed in deionized water, and after adding a surfactant and a coupling agent, the relationship between graphene and titanium dioxide The ratio is 1-5:1000, add nano-titanium dioxide and mix, stir for 40 minutes, dehydrate and dry at 105°C for 8 ho...

Embodiment 2

[0050] An embodiment of the present invention, the preparation method is the same as in Example 1, the difference is that the components are: 20 parts of inorganic resin, 0.2 part of graphene modified anti-formaldehyde auxiliary agent, 0.3 part of multifunctional auxiliary agent, 18.4 parts of deionized water, 5 parts of polymer emulsion, 0.3 part of defoamer, 0.2 part of dispersant, 0.1 part of rheological additive, 0.5 part of thickening additive, pigments and fillers (10 parts of titanium dioxide, 10 parts of kaolin, 20 parts of Pfizer ground calcium carbonate) in total 40 parts, 15 parts of pearl paste; inorganic resin is potassium silicate: silica sol is 1:1 configuration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com