Vacuum film plating method

A vacuum coating and vacuum technology, applied in the field of MEMS manufacturing, can solve the problems of cumbersome process steps and achieve the effect of increasing deposition rate, simple device and small reaction space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The vacuum coating method of the present invention comprises the following steps:

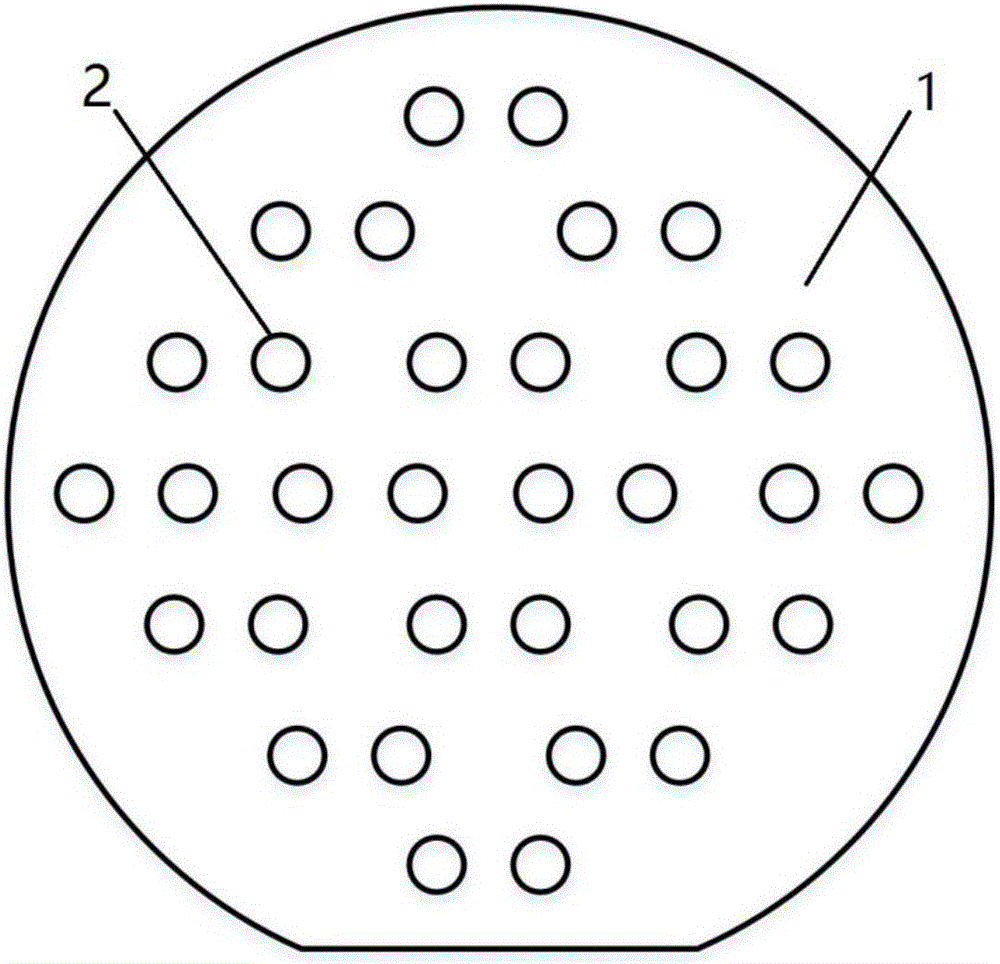

[0043] In the first step, an array of micro through-silicon holes (2) is etched on a silicon wafer (1) (for example, a 4-inch conductive wafer), and the through holes are independent and not connected to each other. The silicon wafer used may be a silicon wafer with a standard thickness, for example, a silicon wafer with a thickness of 500 microns. The diameter of the micro TSV is 1-5 mm, such as 1 mm, 1.5 mm, 1.8 mm, 2 mm, 4 mm, 5 mm. The micromachining process of the pattern structure on the silicon wafer is one of laser drilling process, wet etching process, dry inductively coupled plasma (ICP) etching process or reactive ion etching, and the pattern can be square or a circular through-hole array;

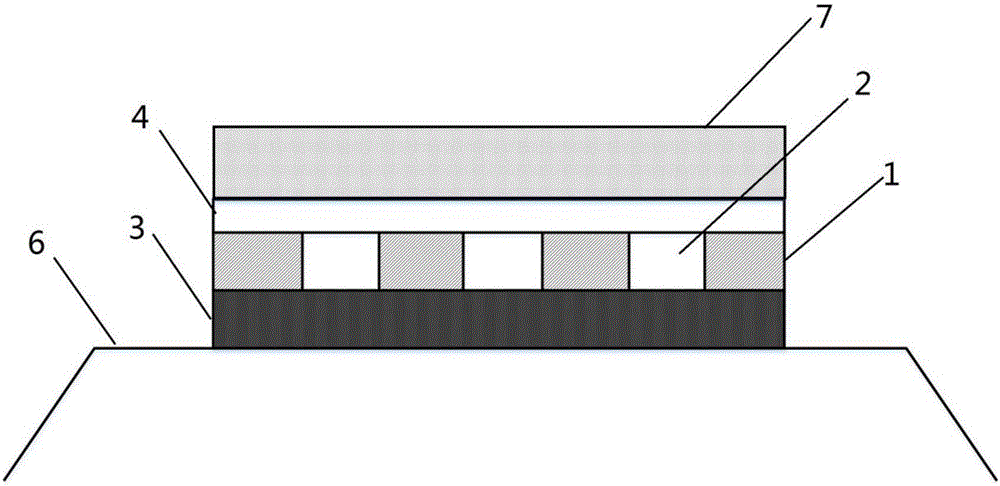

[0044] In the second step, the clean graphite disc (3) is placed on the chassis of the anodic bonding machine. mm, 4 mm, 5 mm, and then place the etched silicon wafer (1) on the graphit...

Embodiment 2

[0049] The vacuum coating method of the present invention comprises the following steps:

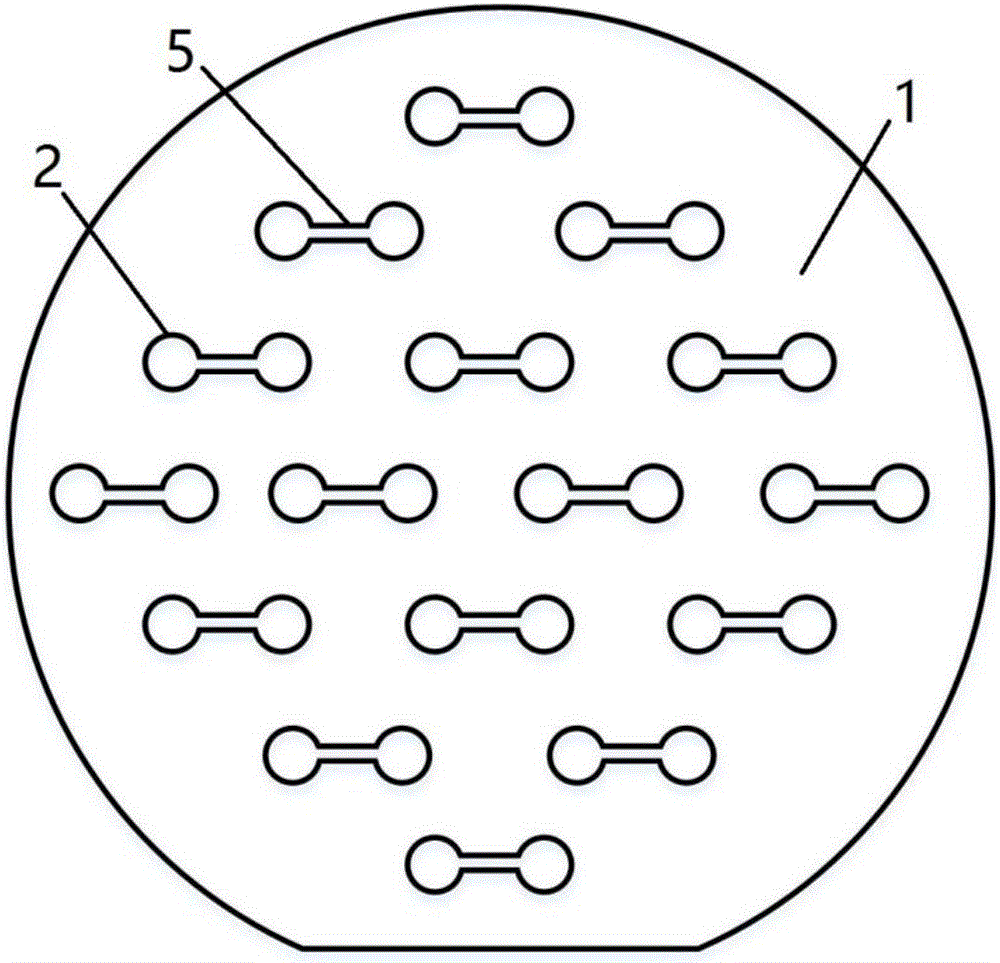

[0050] In the first step, an array of micro through-silicon holes (2) is etched on a silicon wafer (1) (for example, a 4-inch conductive wafer), and the through holes communicate with each other through channels. The silicon wafer used may be a silicon wafer with a standard thickness, for example, a silicon wafer with a thickness of 500 microns. The diameter of the micro TSV is 1-5 mm, such as 1 mm, 1.5 mm, 1.8 mm, 2 mm, 4 mm, 5 mm. The micromachining process of the pattern structure on the silicon wafer is one of laser drilling process, wet etching process, dry inductively coupled plasma (ICP) etching process or reactive ion etching, and the pattern can be square or a circular through-hole array;

[0051] The second step is to place the clean graphite disk (3) on the modified coating equipment chassis. mm, 4 mm, 5 mm, and then place the etched silicon wafer (1) on the graphite wafer ...

Embodiment 3

[0055] The vacuum coating method of the present invention comprises the following steps:

[0056] In the first step, an array of micro through holes (2) is etched on an aluminum wafer (1) (for example, a 4-inch conductive wafer), and the through holes are independent and not connected to each other. The aluminum disc used can be an aluminum disc with a standard thickness, such as an aluminum disc with a thickness of 1 mm. The diameter of the micro through hole is 1-5 mm, such as 1 mm, 1.5 mm, 1.8 mm, 2 mm, 4 mm, 5 mm. The micromachining process of the pattern structure on the silicon wafer is a laser drilling process and a wet etching process, and the pattern can be a square or circular through-hole array;

[0057] In the second step, the cleaned copper disc (3) is placed on the chassis of the anodic bonding machine. mm, 4 mm, 5 mm, and then place the etched aluminum disc (1) on the copper disc (3), and finally place the substrate disc (4). Ensure that the above-mentioned c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com