High-resilience foam material containing rich PAPI (polyaryl polymethylene isocyanate) polyurethane

A foam material and high resilience technology, applied in the field of foam material production, can solve the problems of environment and occupational health and safety impact, difficult low density, poor tear strength, etc., and achieve reasonable distribution of soft and hard segments and high foaming ratio , high elongation and tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the embodiments.

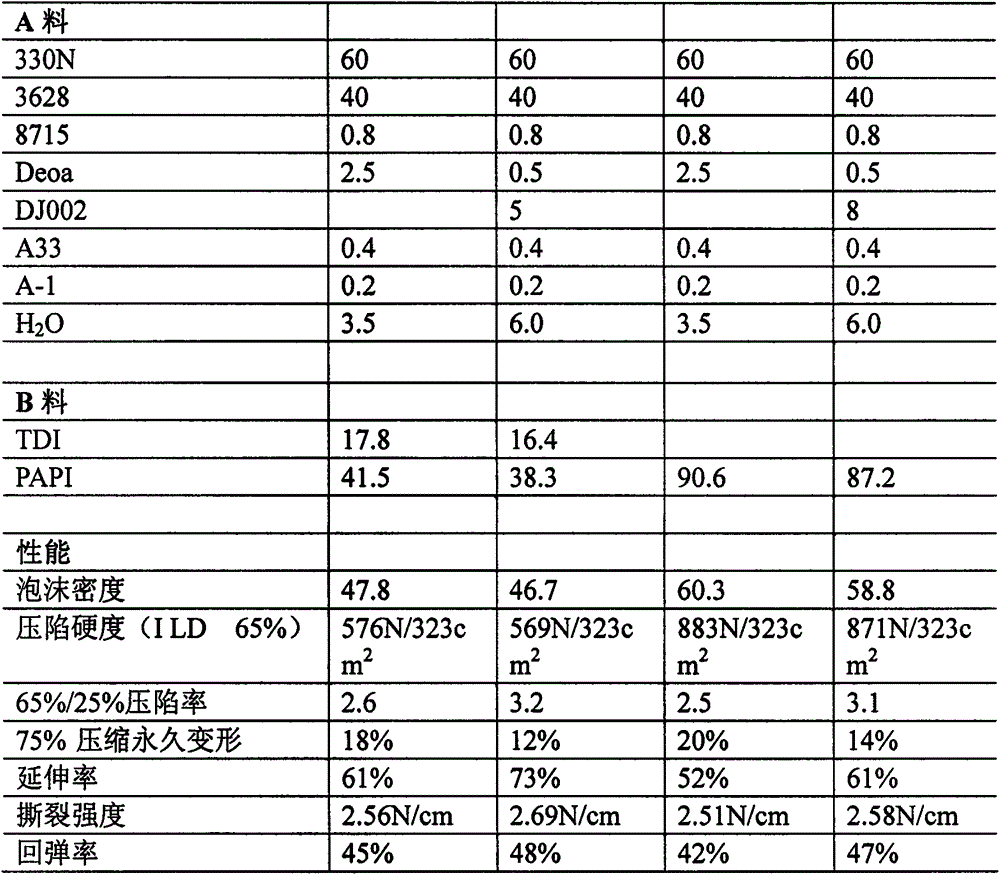

[0015] The formulation of the PAPI-rich polyurethane high resilience foam material of this embodiment is composed of a polyether polyol composition of component A and an isocyanate composition of component B, and the mixing ratio of component A to component B is: 100 parts by weight: 50-70 parts by weight; the proportion of the component A is: polyether 330N: 33-60%, polymer polyol: 33-60%, silicone oil: 0.5-1.5%, catalyst A33: 0.2 ~0.8%, catalyst A-1: 0.2~0.8%, diethanolamine as crosslinking agent: 0.5~3.0%, polyol auxiliary agent DJ002: 3~10%, water as blowing agent: 2.5~6%; The proportion of the component B is: toluene diisocyanate: 0-40%, polymethylene polyphenyl isocyanate: 60-100%, the catalyst A33: prepared from triethylenediamine and dipropylene glycol The resulting solution. The composition ratio of the triethylenediamine and dipropylene glycol solution is: 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com