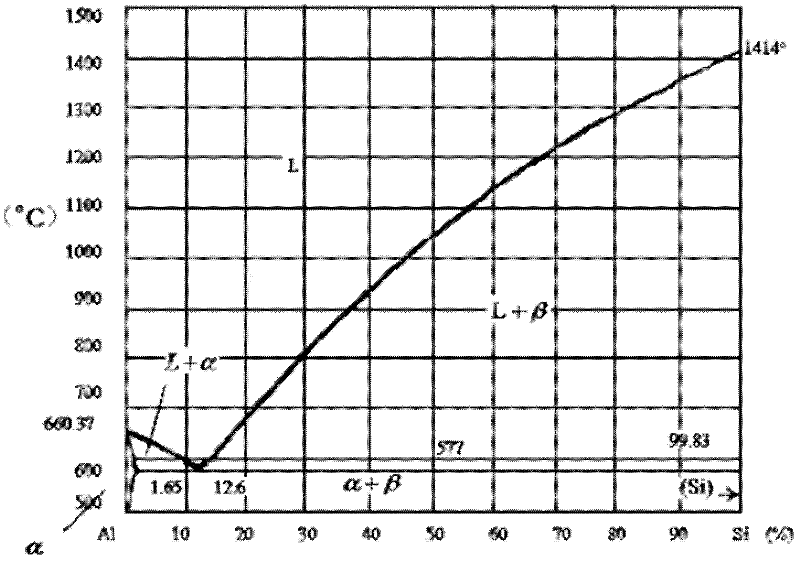

Method for refining hypereutectic aluminum-silicon alloy primary crystal silicon tissues

An aluminum-silicon alloy and hypereutectic technology, applied in the field of metal casting, can solve the problems of energy consumption, limited effect, increase process cycle, etc., and achieve the effects of reducing stress concentration, refining eutectic silicon and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The preparation method is as follows:

[0055] Add the aluminum-silicon alloy raw materials to the melting furnace for mixing, raise the temperature to 760°C and melt for 30 minutes. After melting, detect the composition and adjust it to the required alloy composition. Then keep the temperature constant and refine the alloy liquid with hexachloroethane for 20 minutes. In order to remove hydrogen and non-metallic inclusions, the alloy liquid is heated to 1080°C and maintained for 30 minutes, then cooled to 950°C, and refined with argon for 5-7 minutes to remove gases and oxidized inclusions. Lower the temperature to 760°C, and cool at a cooling rate of 10°C / s after pouring to obtain a hypereutectic aluminum-silicon alloy casting.

Embodiment 2

[0057] The preparation method is as follows:

[0058]Add the aluminum-silicon alloy raw materials to the melting furnace for mixing, heat up to 760°C for 30 minutes, detect the composition after melting and adjust to the required alloy composition, refine the alloy liquid with hexachloroethane for 20 minutes to obtain the alloy liquid, so as to remove Hydrogen and non-metallic inclusions, the resulting alloy liquid is poured and cooled at a cooling rate of 10°C / s to obtain a hypereutectic aluminum-silicon alloy casting.

Embodiment 3

[0060] The preparation method is as follows:

[0061] Add the aluminum-silicon alloy raw materials to the melting furnace for mixing, heat up to 760°C for 30 minutes, detect the composition after melting and adjust to the required alloy composition, refine the alloy liquid with hexachloroethane for 20 minutes to obtain the alloy liquid, so as to remove Hydrogen and non-metallic inclusions, the alloy liquid is heated to 950°C and maintained for 30 minutes, then refined with argon for 5-7 minutes to remove gas and oxidized inclusions, cooled to 760°C under the protection of the covering agent, and cast Afterwards, the hypereutectic aluminum-silicon alloy casting is obtained by cooling at a cooling rate of 10° C. / second.

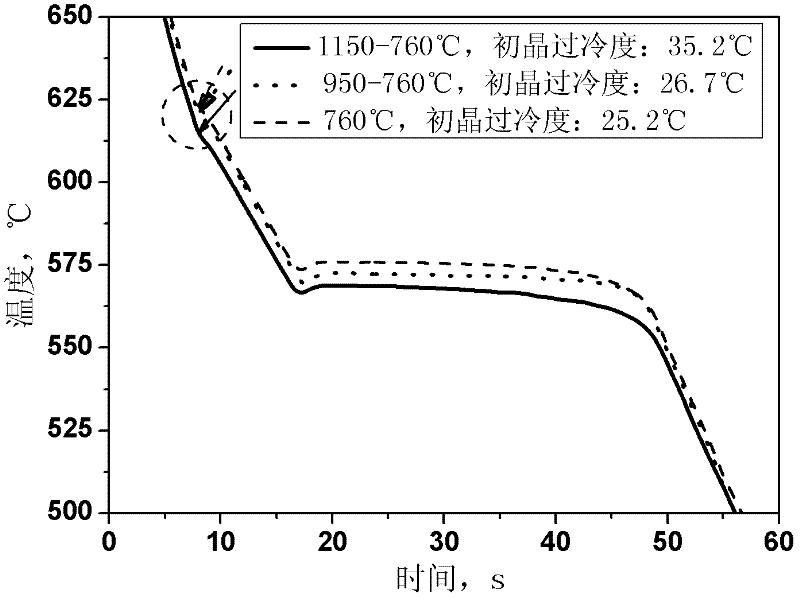

[0062] The comparative analysis of embodiment 1-3:

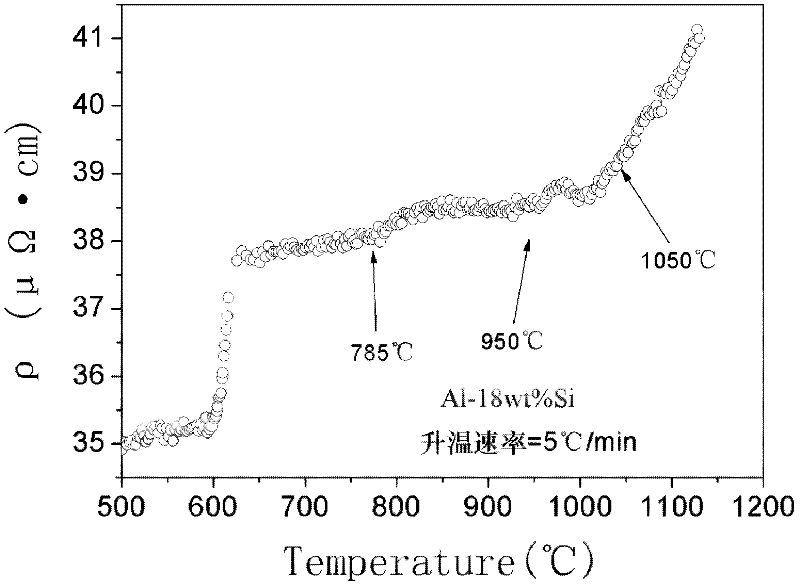

[0063] In the case of pure melt superheating process, the effect of effectively refining primary silicon can only be obtained after the melt structure and property state have really changed. image 3 with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com