Method for producing solanaceous vegetable seedling growing substrate by utilizing salvaged material of cassava processing

The technology of a vegetable seedling substrate and a production method is applied in the field of producing a solanaceous vegetable seedling substrate, and can solve the problems of pollution, low utilization rate of waste, waste of resources, environment and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

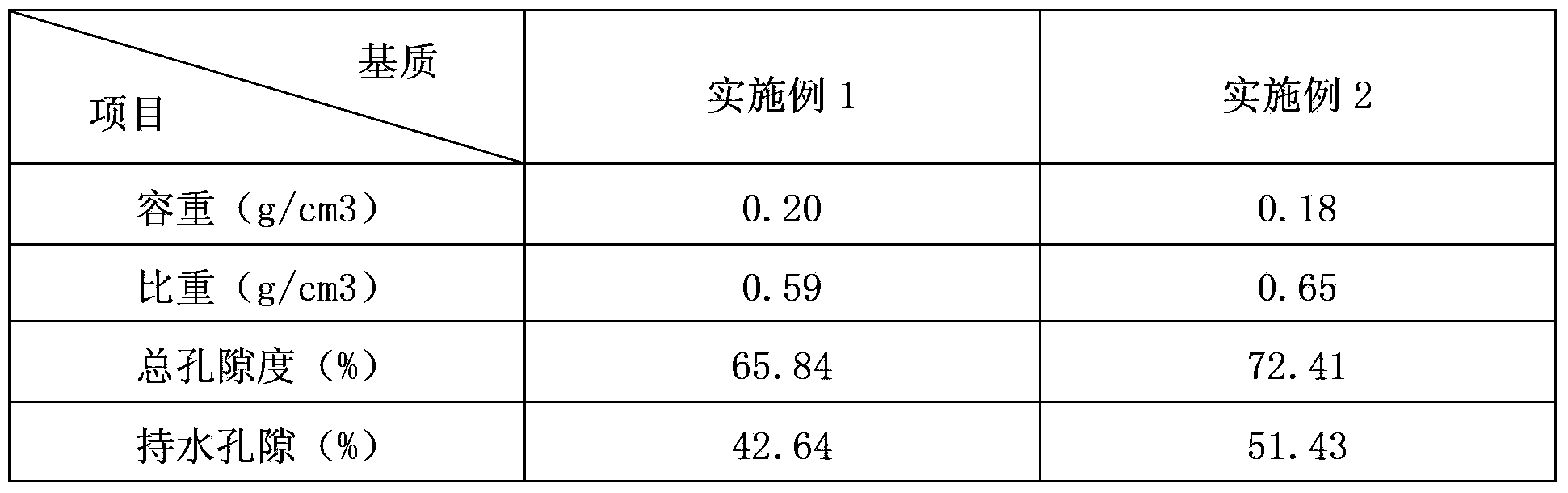

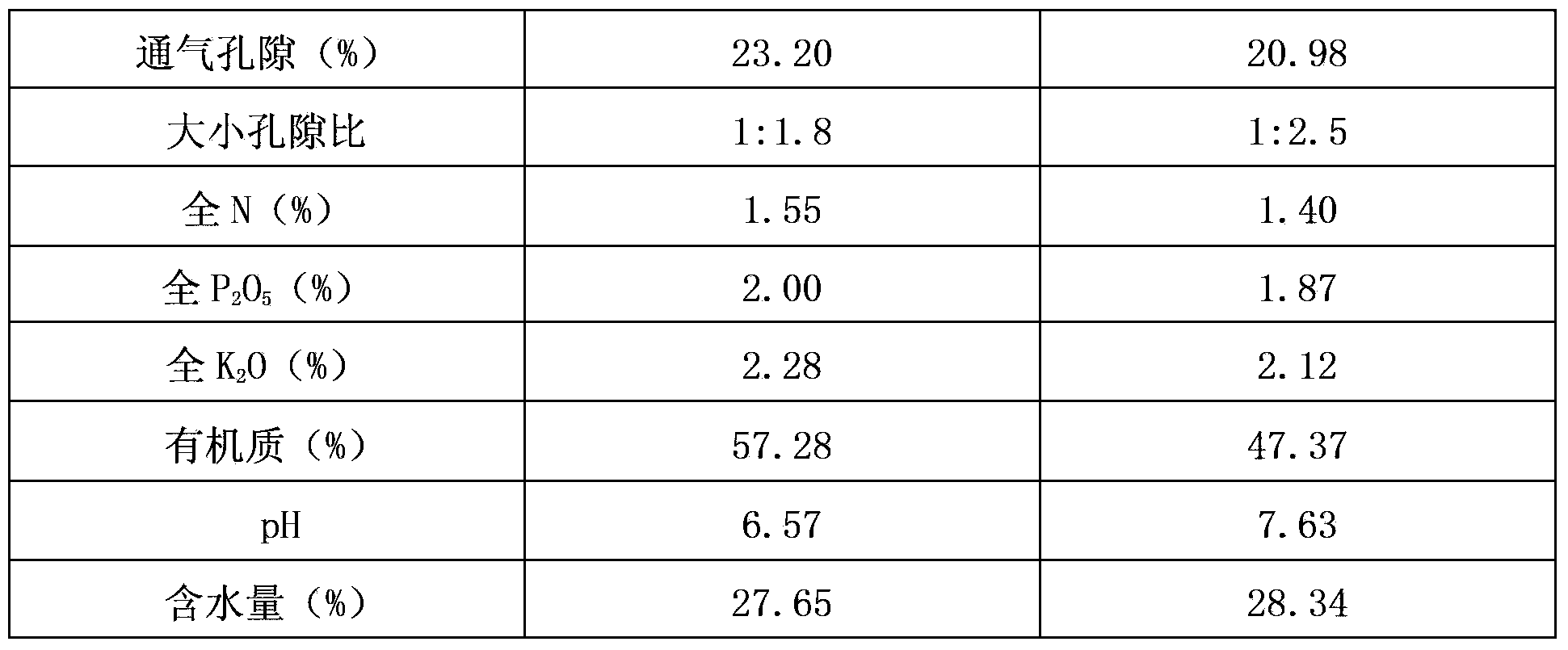

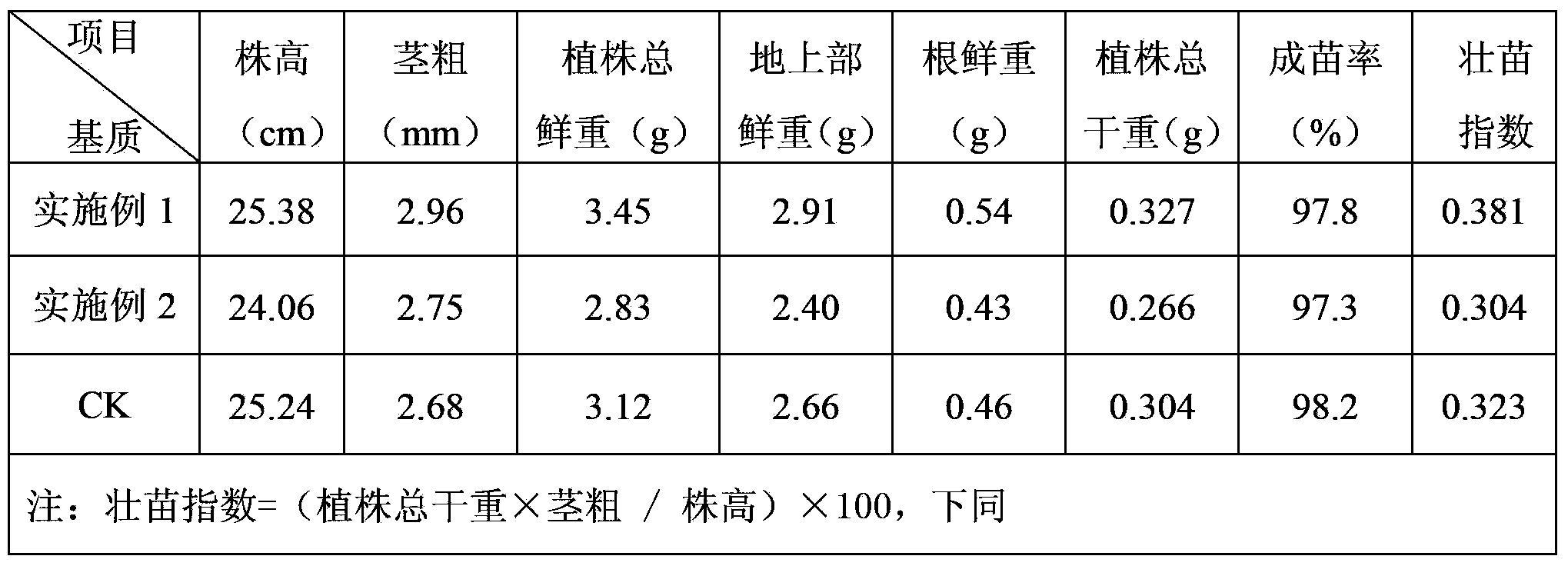

Examples

Embodiment 1

[0031] (1) After mixing cassava skin, starch residue, chicken manure, and tung bran in a volume ratio of 4:3:2:1, add 2.0kg of microbial fermentation agent to every 1000kg of raw materials, and fully stir and mix;

[0032] (2) Use 15.0kg of urea to adjust the C / N mass ratio of 1000kg of fermented product in step (1) to 25:1, and carry out compost fermentation after thorough mixing; stack the mixed fermented product in the turning tank of the fermentation field , ferment according to the pile height of 0.8-1.0 meters and width of 1.0 meters, and monitor the temperature and water content of the pile; during the fermentation process, the water content is controlled at 55%-65%; after the composting of the mixed fermented material begins, within 30 days, Every 3 to 5 days, use a tractor knife rake to turn the pile once. When the fermentation temperature rises to 60-70°C and keeps for 48 hours, turn the pile. But when the temperature exceeds 70°C, turn the pile immediately. Be sure ...

Embodiment 2

[0035] (1) After mixing cassava skin, starch residue, chicken manure, and shell powder in a volume ratio of 5:2:2:1, add 2.0kg of microbial fermentation agent to every 1000kg of waste raw materials, and fully stir and mix;

[0036](2) Use 12.0kg of urea to adjust the C / N mass ratio of 1000kg of fermented product in step (1) to 30:1, and carry out compost fermentation after fully mixing; stack the mixed fermented product in the turning tank of the fermentation field , ferment according to the pile height of 0.8-1.0 meters and width of 1.0 meters, and monitor the temperature and water content of the pile; during the fermentation process, the water content is controlled at 55%-65%; after the composting of the mixed fermented material begins, within 30 days, Every 3 to 5 days, use a tractor knife rake to turn the pile once. When the fermentation temperature rises to 60-70°C and keeps for 48 hours, turn the pile. But when the temperature exceeds 70°C, turn the pile immediately. Be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com