Method for producing tungsten and tin chemical products through chemical metallurgical separation of tungsten-tin paragenic ore

A chemical product, tungsten-tin technology, which is applied in the field of tungsten-tin symbiotic ore to produce tungsten and tin chemical products, which can solve problems such as difficult separation, affecting the quality of tin and tin products, and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

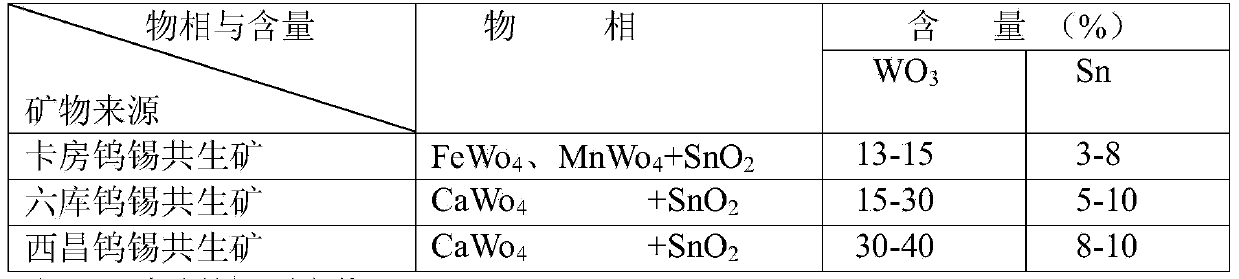

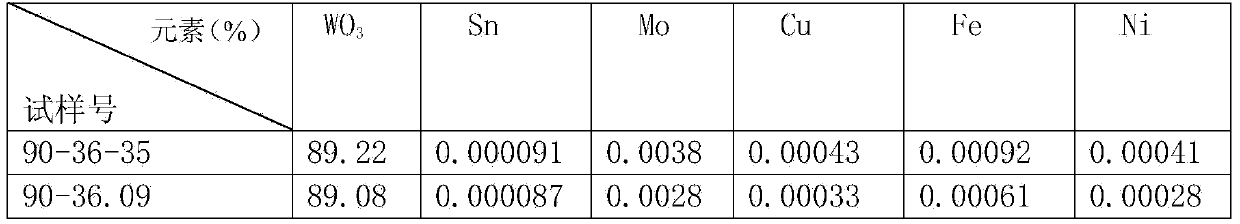

[0038] Example 1: Production of ammonium paratungstate and tin dioxide from Gejiu Kafang tungsten-tin symbiotic mine in Yunnan

[0039] The main chemical composition of raw ore is: WO 3 is 13.48%, Sn is 4.13%;

[0040] The main component phase of raw ore is: FeWO 4 .MnWO 4 +SnO 2 ;

[0041] Main process: mineral wet grinding, dilute nitric acid conversion; tungsten immersion in ammonia water, ion exchange, ammonium analysis, concentrated crystallization to produce ammonium paratungstate; tin slag lignite reduction, sulfuric acid leaching, liquid phase oxidation, dehydration and drying to obtain tin dioxide; ammonia water as Absorb conversion agent to recover nitrogen oxides produced by acid hydrolysis; convert ammonium carbonate precipitation to recover metal ions; tungsten liquid mother liquor is separated from the alkaline analysis to recover tungsten; immersion tin mother liquor is treated by lime-bleaching powder-ferrous method to meet the standard discharge.

[0042]...

example 2

[0088] Example 2: Production of ammonium paratungstate and tin dioxide from tungsten-tin symbiotic mine in Tengchong, Yunnan

[0089] The main chemical composition of raw ore is: WO 3 is 16.21%, Sn is 6.82%;

[0090] The main component phase of raw ore is: CaWO 4 +SnO 2

[0091] Main technological process: the same as Example 1, such as

[0092] Grinding particle size: -120 mesh ≥ 95%

[0093] Dilute nitric acid conversion process conditions:

[0094] Nitric acid concentration: 9%

[0095] Nitric acid dosage: solid: liquid = 1:3

[0096] Reaction temperature: 95°C

[0097] Response time: 120 minutes

[0098] Ammonia water immersion tungsten process conditions are the same as Example 1

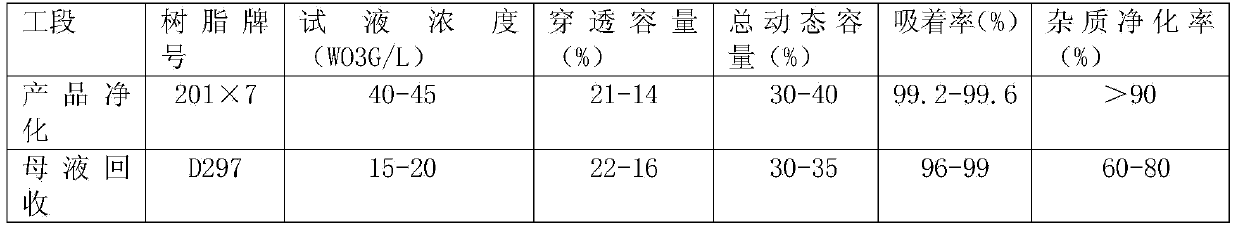

[0099] Tungsten ionization purification and analysis process conditions:

[0100] Tungsten liquid concentration: ~45 (WO 3 g / l)

[0101] Resin grade, analytical agent and concentration: same as Example 1

[0102]Tungsten mother liquor recovery separation and analysis process condi...

example 3

[0113] Example 3: Ammonium paratungstate and tin dioxide in Xichang tungsten-tin symbiotic mine in Sichuan

[0114] The main chemical composition of raw ore is: WO 3 is 39.16%, Sn is 7.22%;

[0115] The main component phase of raw ore is: CaWO 4 +SnO 2

[0116] Main technological process: the same as Example 1

[0117] Grinding particle size: ~ 120 mesh ≥ 95%

[0118] Dilute nitric acid conversion process conditions:

[0119] Nitric acid concentration: 9%

[0120] Nitric acid dosage: solid: liquid = 1:3

[0121] Reaction temperature: 95°C

[0122] Reaction time: 120min

[0123] Ammonia water immersion tungsten process conditions are the same as Example 1

[0124] Ammonium separation purification and analysis process conditions:

[0125] Tungsten liquid concentration: ~45 (WO 3 g / l)

[0126] Resin grade, analytical agent and concentration: same as Example 1

[0127] Tungsten mother liquor recovery separation and analysis process conditions:

[0128] Mother liquor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com