Process of purifying and recovering waste gas containing volatile organic compound and its application

A technology of organic compounds and recovery methods, applied in the field of recovery and purification of waste gas containing volatile organic compounds, can solve problems such as damage, air pollution, and shortened lifespan, and achieve high flexibility in process selection, huge economic benefits, and increased service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

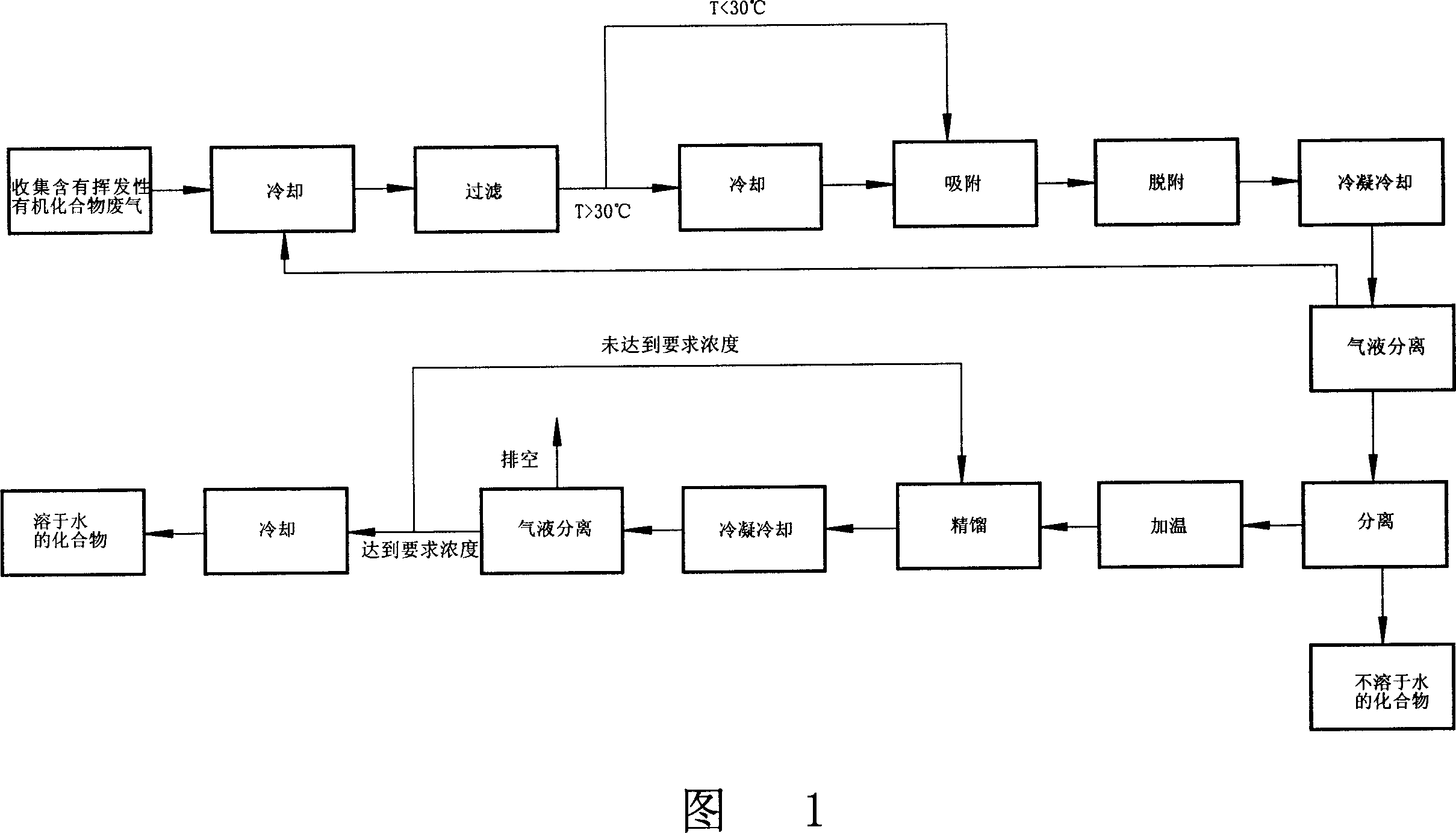

[0026]As shown in Figure 1, the present invention reclaims and purifies the method of waste gas containing volatile organic compounds from a printing machine that prints cigarette tipping paper. Tipping paper is special paper for cigarette filter tip outsourcing and is an indispensable material in the cigarette production process one. The tipping paper is mainly used to wrap the acetate fiber that absorbs the tar, which is beautiful and convenient for suction. In the printing production process of printing tipping paper, a large amount of ethanol and a small amount of organic solvents such as ethyl acetate and ethylene glycol ether are used to dissolve polymer resins, and the organic solvents are used in the process of drying the coating with hot air to form a film. All are volatilized, and the method for recovering the above-mentioned waste gas containing ethanol, ethyl acetate and ethylene glycol ether includes: collecting the above-mentioned waste gas containing ethanol, et...

Embodiment 2

[0029] As shown in Figure 1, the present invention reclaims and purifies the method for waste gas containing volatile organic compounds from ordinary printing machines. According to different printing requirements, the types of printing inks are different. The types of compound waste gases are also different, which are only illustrated in this embodiment. In the printing production process, a large amount of acetone and a small amount of organic solvents such as toluene and xylene are used to dissolve the polymer resin in the ink. During the process of drying the coating with hot air to form a film, the organic solvent is all volatilized. Recover the above-mentioned volatile The method of organic compound exhaust gas includes: collecting the above-mentioned exhaust gas of acetone, toluene and xylene with a collector, these exhaust gases include a large amount of acetone, a small amount of toluene and xylene and entrained printing paper dust, dissolved polymer resin and titanium...

Embodiment 3

[0031] As shown in Figure 1, the present invention reclaims and purifies the method of waste gas containing volatile organic compounds from the banknote printing machine. In the banknote printing machine, water-insoluble banknote printing oil is usually used to dissolve the ink. The banknote printing oil belongs to mineral oil and petroleum. Distillate, it contains kerosene, straight-chain alkanes, cycloalkanes and other easily volatile organic compounds, the organic solvents are all volatilized in the process of coating drying and film formation, and the smell of the banknote printing workshop is relatively strong, the method of recovering the waste gas containing banknote printing oil above Including: using a collector to collect the above-mentioned waste gas containing banknote printing oil. These waste gases include: banknote printing oil, entrained printing paper scraps and dissolved polymer resin. After cooling the above-mentioned waste gas to about 40°C, it is first sent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com