Production method for activated carbon

A production method, activated carbon technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as difficult application and promotion, excessive dust on the surface, and poor strength of activated carbon, so as to reduce production costs and avoid serious pollution , the effect of high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

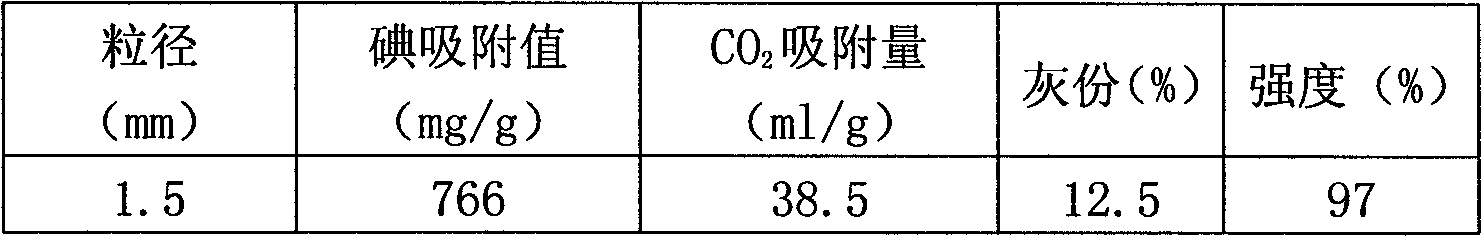

Embodiment 1

[0021] 1. Provide 100kg of anthracite powder and put it in the kneader, add an appropriate amount of water, keep stirring and kneading for 10 minutes, then add 7kg of corn starch adhesive, 10kg of active silicic acid, and 8kg of potassium polyphosphate, and continue kneading for 10 minutes. , the material has a certain degree of plasticity under pressure.

[0022] 2. Extrusion: Put the above-mentioned kneaded material with a certain degree of plasticity into a press equipped with a mold, the working pressure is 150kg / cm-250kg / cm, and after extrusion, it becomes a columnar strip with a diameter of 2.0mm-5.0mm; Columnar strips have certain wet strength and toughness, and will not stick to each other. After wind drying, the strength is further improved.

[0023] 3. Drying: Put the columnar strips into the dryer for drying, the speed of the dryer is 1-3 rpm, the temperature is 150°C-180°C, and the drying time is about 1 hour;

[0024] 4. Activation: Put the dried strips into the...

Embodiment 2

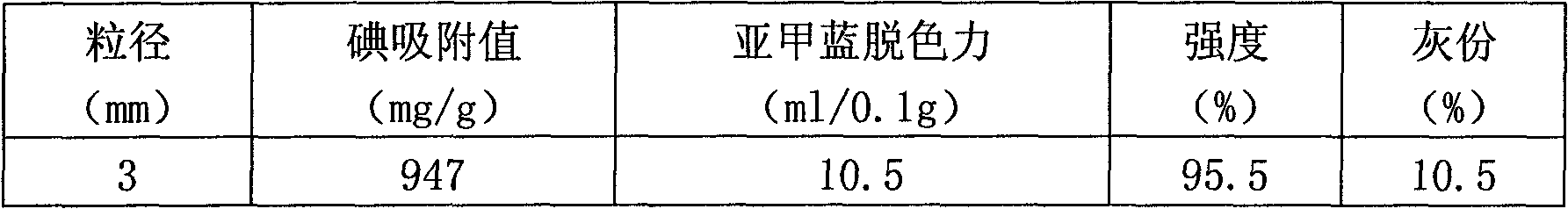

[0029] Coal fraction 100kg is provided, carboxymethyl cellulose 5kg, polyvinyl alcohol 2kg, active silicic acid 25kg, adopt the method described in embodiment 1, the main technical index of the gac produced after kneading, extruding, drying, activation is as follows:

[0030]

[0031] This activated carbon is used in pressure swing adsorption for CO 2 It can also be used in desulfurization, water treatment and other industries.

Embodiment 3

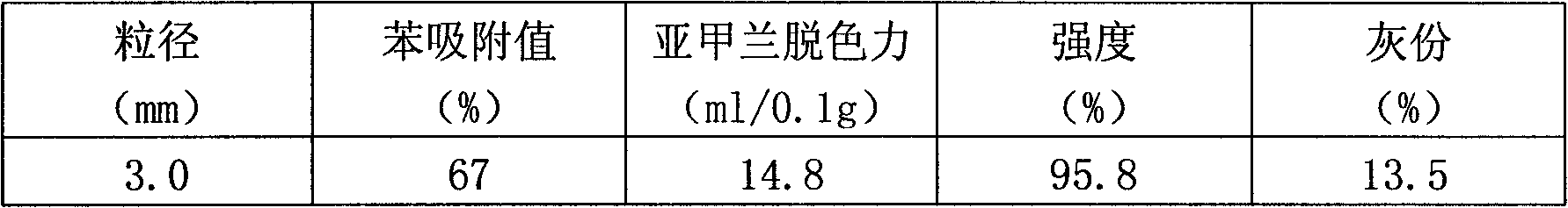

[0033] Provide 50kg of anthracite coal powder, 30kg of charcoal powder, 20kg of waste activated carbon, and 20kg of coal tar, 10kg of sodium metapolyphosphate, adopt the method described in Example 1, through kneading, extruding, drying, and activation, the technical indicators of the granular activated carbon produced are as follows :

[0034]

[0035] This granular activated carbon can be used for gas phase adsorption, such as gasoline gas recovery, benzene vapor recovery, and decolorization and deodorization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com