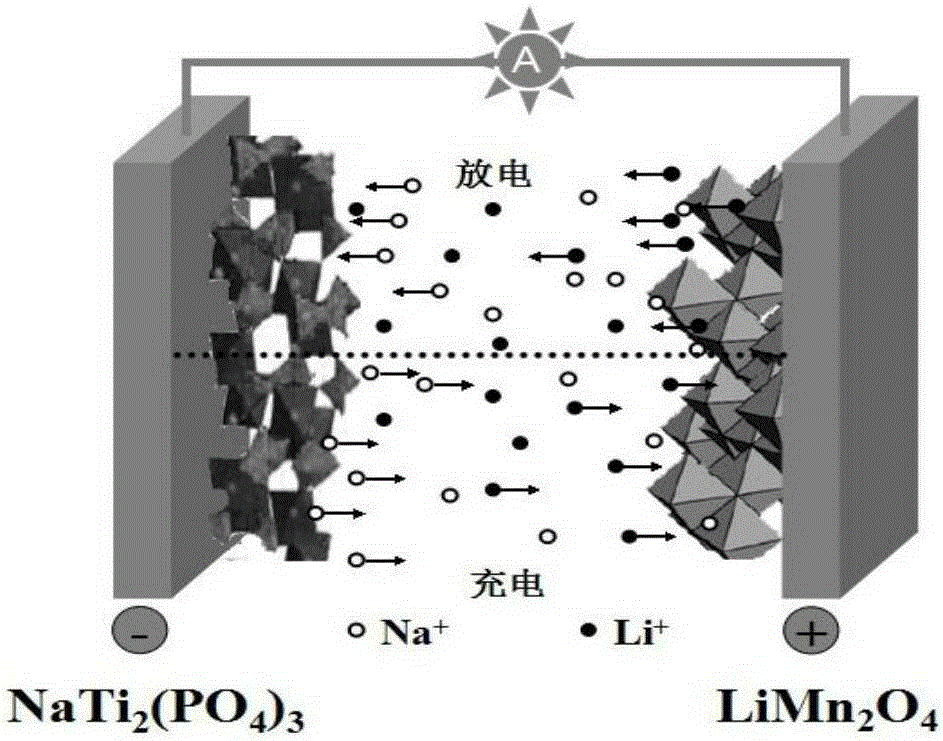

Aqueous ion-exchange cell

An ion-exchange battery, water system technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high price, high consumption, limited lithium reserves, etc., and achieve the effect of low production cost, high power density, and rich content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation process of the positive / negative pole of the present invention and LiMn 2 o 4 -NaTi 2 (PO4) 3 The assembly steps of the / C battery system are as follows:

[0029] (1) LiMn 2 o 4 Preparation of positive electrode

[0030] With Li 2 CO 3 and MnCO 3 As raw materials, nano-scale spinel-type LiMn was prepared by high-temperature solid-phase synthesis. 2 o 4 . (Reference HaishengTao, ShuqiongZhang, YingyingCheng, XuemeiZhang, Nanosci.Nanotechnol.Lett.7, 555-559(2015))

[0031] (2)NaTi 2 (PO 4 ) 3 and NaTi 2 (PO 4 ) 3 Preparation of / C negative electrode

[0032] with C 4 h 4 o 5 Na (sodium hydrogen tartrate), TiO 2 , (NH 4 ) 2 HPO 4 As a raw material, the precursor was obtained by sol-gel method, and then NaTi was prepared by calcination 2 (PO 4 ) 3 .

[0033] with C 4 h 4 o 5 Na (sodium hydrogen tartrate), TiO 2 , (NH 4 ) 2 HPO 4 and (CH 2 Oh) 2 As a raw material, the precursor was obtained by sol-gel method, and then NaT...

Embodiment 1

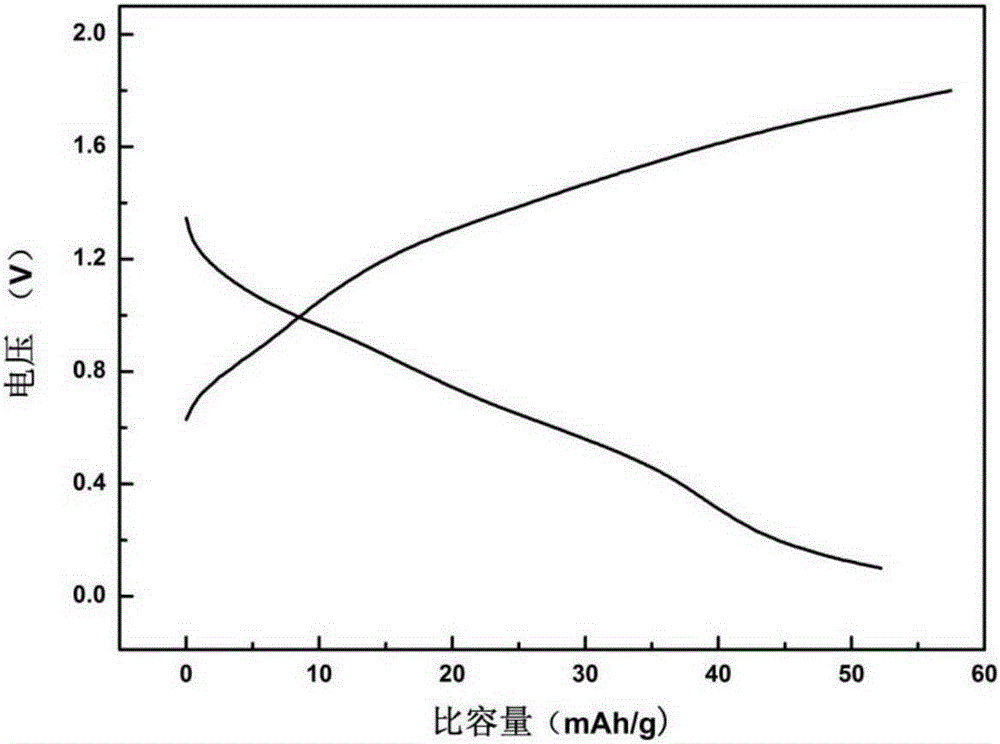

[0037] The active material, the conductive agent and the binder are evenly mixed, coated on the current collector, dried, and pressed into positive and negative electrode films respectively. A full battery is assembled using glass fiber as a separator and an aqueous solution containing sodium and lithium ions as an electrolyte.

[0038] The cathode material is commercially available LiMn 2 o 4 (Qingdao Xinzheng Lithium Industry Co., Ltd.), the proportion of slurry is according to LiMn 2 o 4: Conductive carbon black: binder (the binder is polyvinylidene fluoride, referred to as PVDF) = 80:10:10 mass ratio is fully mixed, then evenly coated on the carbon paper current collector, dried and pressed into a positive electrode .

[0039] The negative electrode material is NaTi 2 (PO 4 ) 3 , the negative electrode slurry is composed of NaTi 2 (PO 4 ) 3 : Conductive carbon black: binder = 75:15:10 mass ratio mixed, then evenly coated on the carbon paper current collector, dri...

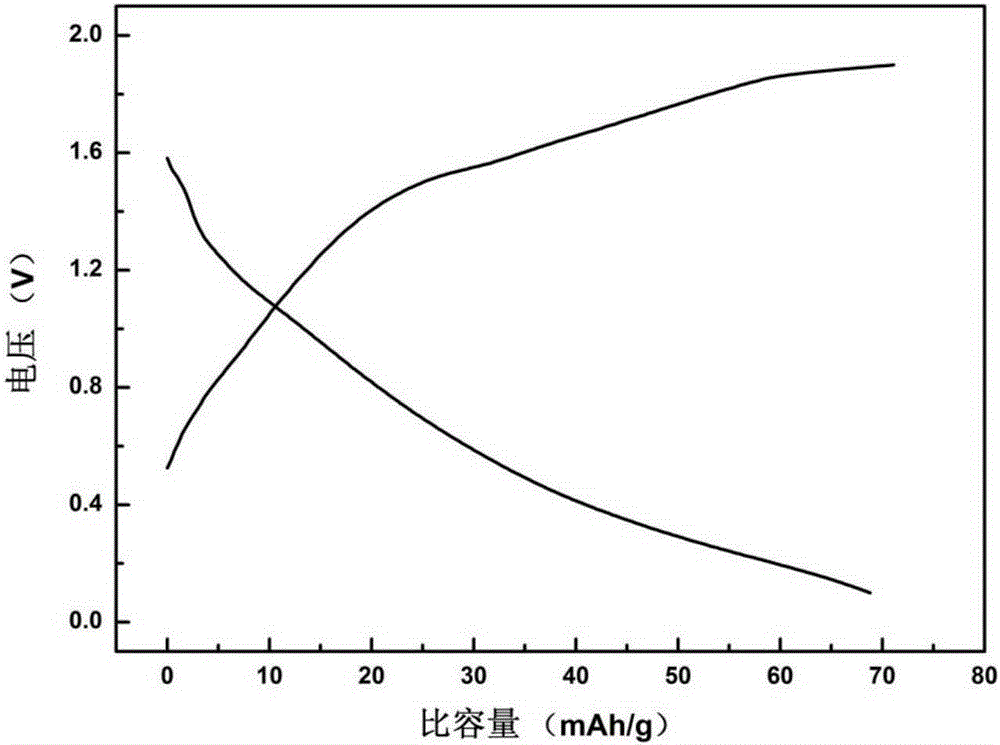

Embodiment 2

[0043] Prepare positive / negative electrode material according to the method for embodiment 1, positive electrode material adopts commercially available LiMn 2 o 4 , the proportion of slurry is according to LiMn 2 o 4 : conductive carbon black: binder = 80:10:10 mass ratio fully mixed, then evenly coated on the carbon paper current collector, dried and pressed to form a positive electrode.

[0044] The negative electrode material is NaTi 2 (PO 4 ) 3 / C, the composition of negative electrode slurry is NaTi 2 (PO 4 ) 3 / C: conductive carbon black: binder = 80:10:10 mass ratio mixed, then evenly coated on the carbon paper collector, dried and pressed to form a negative electrode. In this embodiment, the actual capacity of the positive electrode material is 85mAh / g, the negative electrode is 95mAh / g, and the coating amount of the positive electrode is 10mg / cm 2 , negative electrode 7mg / cm 2 , with glass fiber as the diaphragm, 0.5mol / LNa 2 SO 4 and 0.5mol / LLi 2 SO 4 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com