Method for preparing adsorbent by using semi-coke modification

A technology of adsorbent and semi-coke, which is applied in the field of modified semi-coke to prepare adsorbents, which can solve the problems of strong corrosion of equipment, large environmental pollution, and high concentration, and achieve the effects of simple preparation process, avoiding serious pollution, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Grind and sieve the blue charcoal to obtain blue charcoal powder of 100-120 mesh; according to the solid-to-liquid ratio of 1:5g / mL, add the blue charcoal powder to the nitric acid aqueous solution with a concentration of 2mol / L, and stir the reaction at 70°C 24h, then filter the precipitate, bake the precipitate at 100°C for 3 hours, put it in a muffle furnace, activate it at 400°C for 20min, cool it down to room temperature naturally, take out the product and grind it to about 200 mesh to get the adsorbent product.

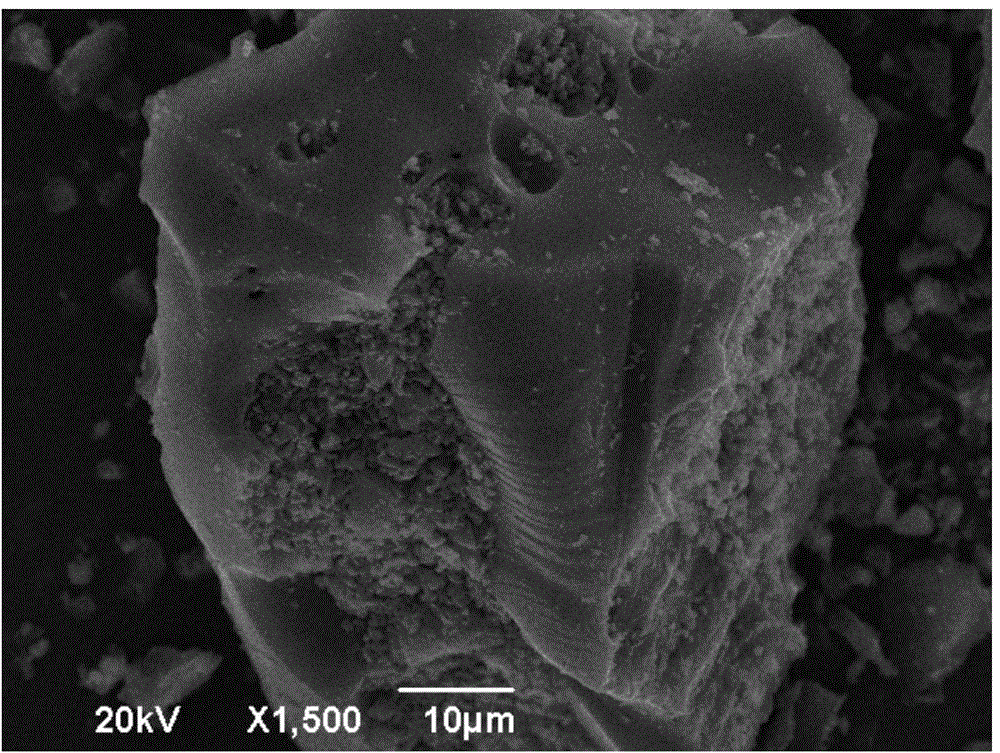

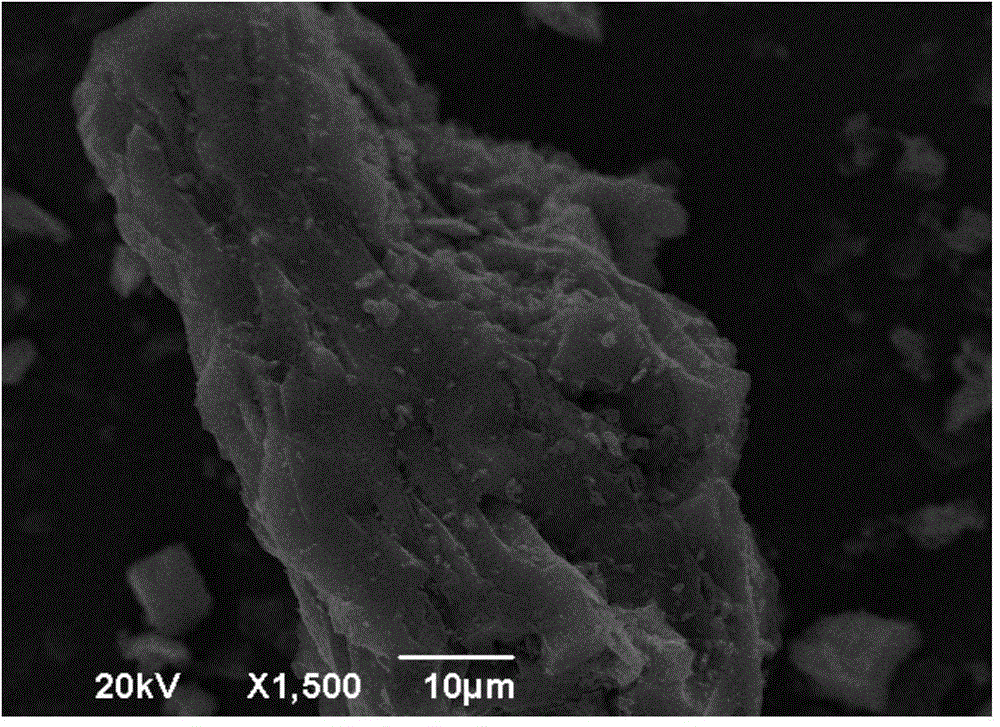

[0023] The SEM photo of the raw material blue charcoal used in this embodiment is as figure 1 As shown, the SEM photo of the obtained adsorbent product is as follows figure 2 As shown, it can be seen from the figure that after the blue carbon is activated according to the method of the present invention, the roughness of the blue carbon surface increases significantly, the surface pores increase significantly, the internal pores are opened to a certain ...

Embodiment 2

[0026] Grind and sieve the blue charcoal to obtain blue charcoal powder of 180-200 mesh; according to the solid-to-liquid ratio of 1:15g / mL, add the blue charcoal powder to the nitric acid aqueous solution with a concentration of 3mol / L, and stir the reaction at 90°C 24h, then filter the precipitate, bake the precipitate at 100°C for 6 hours, put it in a muffle furnace, activate it at 400°C for 20min, cool it down to room temperature naturally, take out the product and grind it to about 200 mesh to get the adsorbent product.

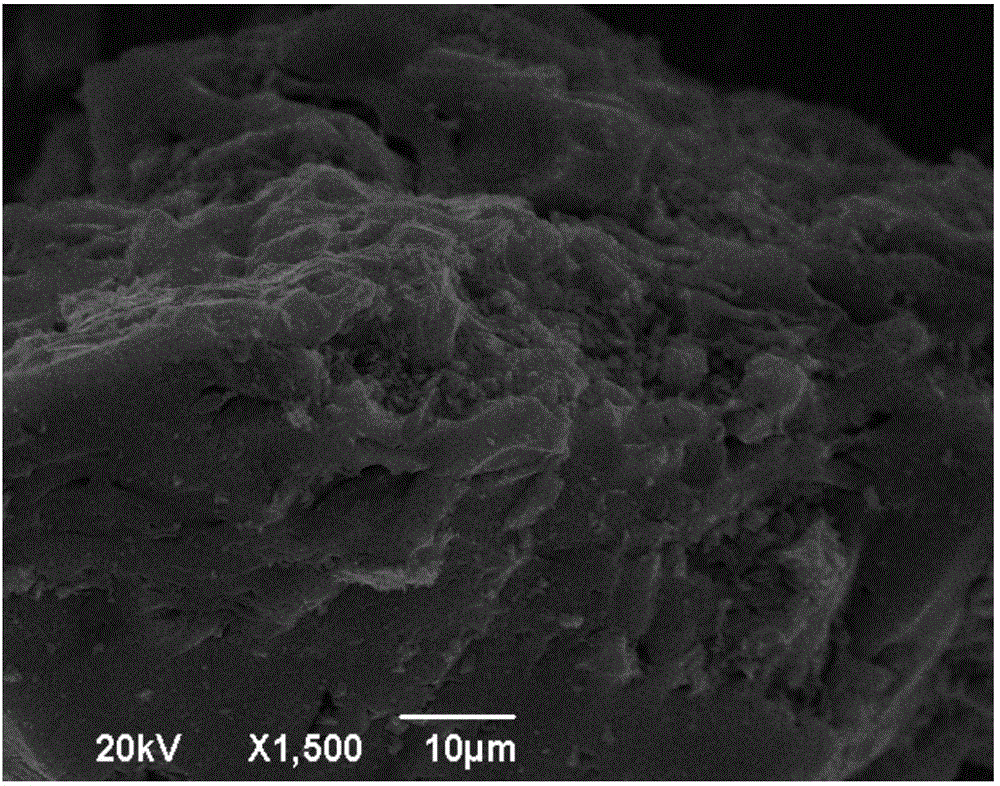

[0027] The SEM photo of the raw material blue charcoal used in this embodiment is as figure 1 As shown, the SEM photo of the obtained adsorbent product is as follows image 3 As shown, it can be seen from the figure that after the blue carbon is activated according to the method of the present invention, the roughness of the blue carbon surface increases significantly, the surface pores increase significantly, the internal pores are opened to a certain ...

Embodiment 3

[0030] Grind and sieve the blue charcoal to obtain blue charcoal powder of 180-200 mesh; according to the solid-to-liquid ratio of 1:10g / mL, add the blue charcoal powder to the nitric acid aqueous solution with a concentration of 4mol / L, and stir the reaction at 90°C 24h, then filter the precipitate, bake the precipitate at 100°C for 6 hours, put it in a muffle furnace, activate it at 400°C for 20min, cool it down to room temperature naturally, take out the product and grind it to about 200 mesh to get the adsorbent product.

[0031] The SEM photo of the raw material blue charcoal used in this embodiment is as figure 1 As shown, the SEM photo of the obtained adsorbent product is as follows Figure 4 As shown, it can be seen from the figure that after the blue carbon is activated according to the method of the present invention, the roughness of the blue carbon surface increases significantly, the surface pores increase significantly, the internal pores are opened to a certain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com