Oil and gas well cementation and completion method

A technology for cementing and completing wells and oil and gas wells, which is applied to wellbore/well components, earthwork drilling, and fluid production, etc. It can solve the problems of oil and gas layer pollution, contaminate oil layers, reduce the effect of underbalanced drilling to protect oil and gas layers, etc. The effect of mutual influence and avoiding serious pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

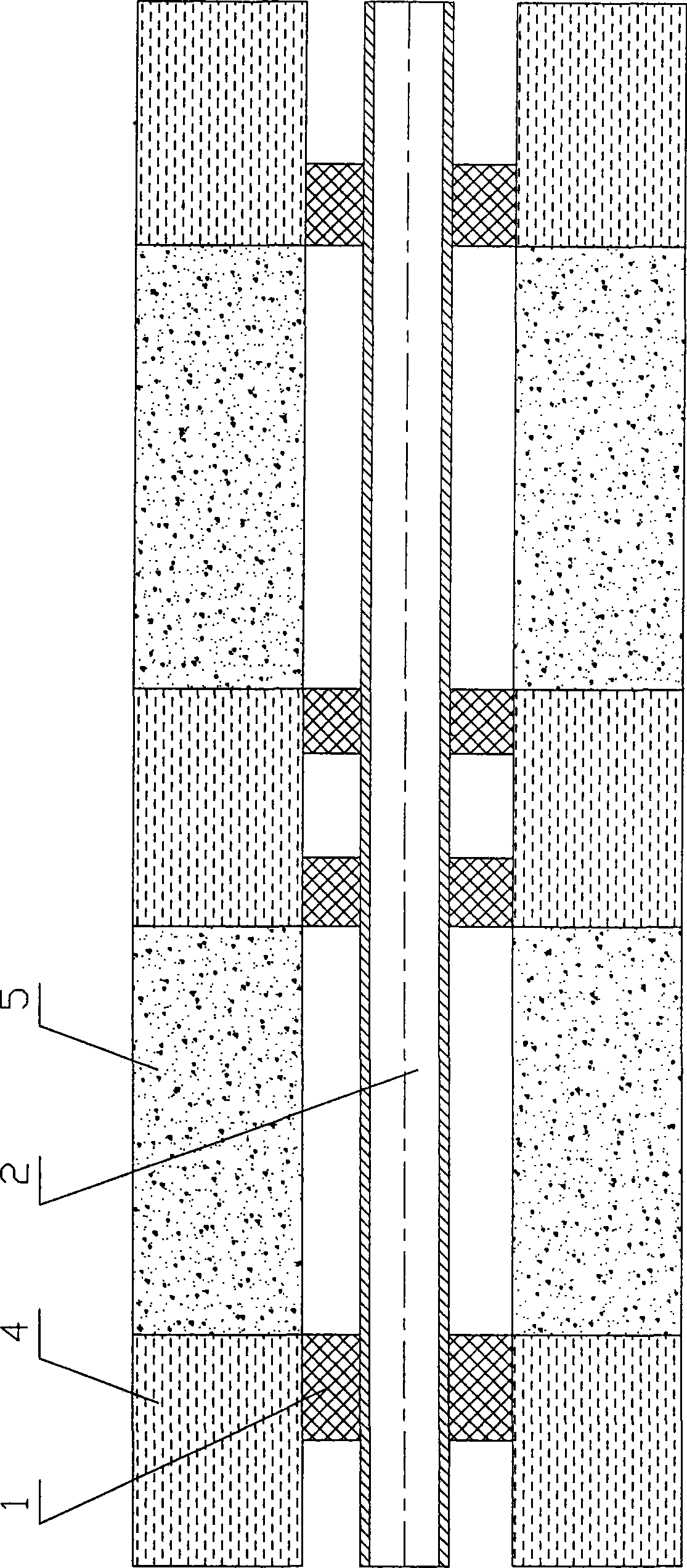

Embodiment 1

[0022] The steps of embodiment one:

[0023] One is after the underbalanced drilling operation is completed, the drill string in the well is raised, and the downhole control valve (the authorized patent ZL2004200501613 declared by the Drilling Technology Research Institute of Xinjiang Petroleum Administration Bureau on April 22, 2004) or other downhole control valves or other non-pressurized valves are closed. The well tripping device, according to the measured position of the oil and gas layer and the predetermined interlayer isolation plan, configures a certain number and appropriate type of packers 1 on the completion string 2, and the packers 1 are filled with cement type packer, the length of the uppermost packer on the pipe string from the bottom end face of the completion pipe string should be less than the running depth of the downhole control valve;

[0024] The second is to run into the completion string 2, and when it reaches the top of the downhole control valve, i...

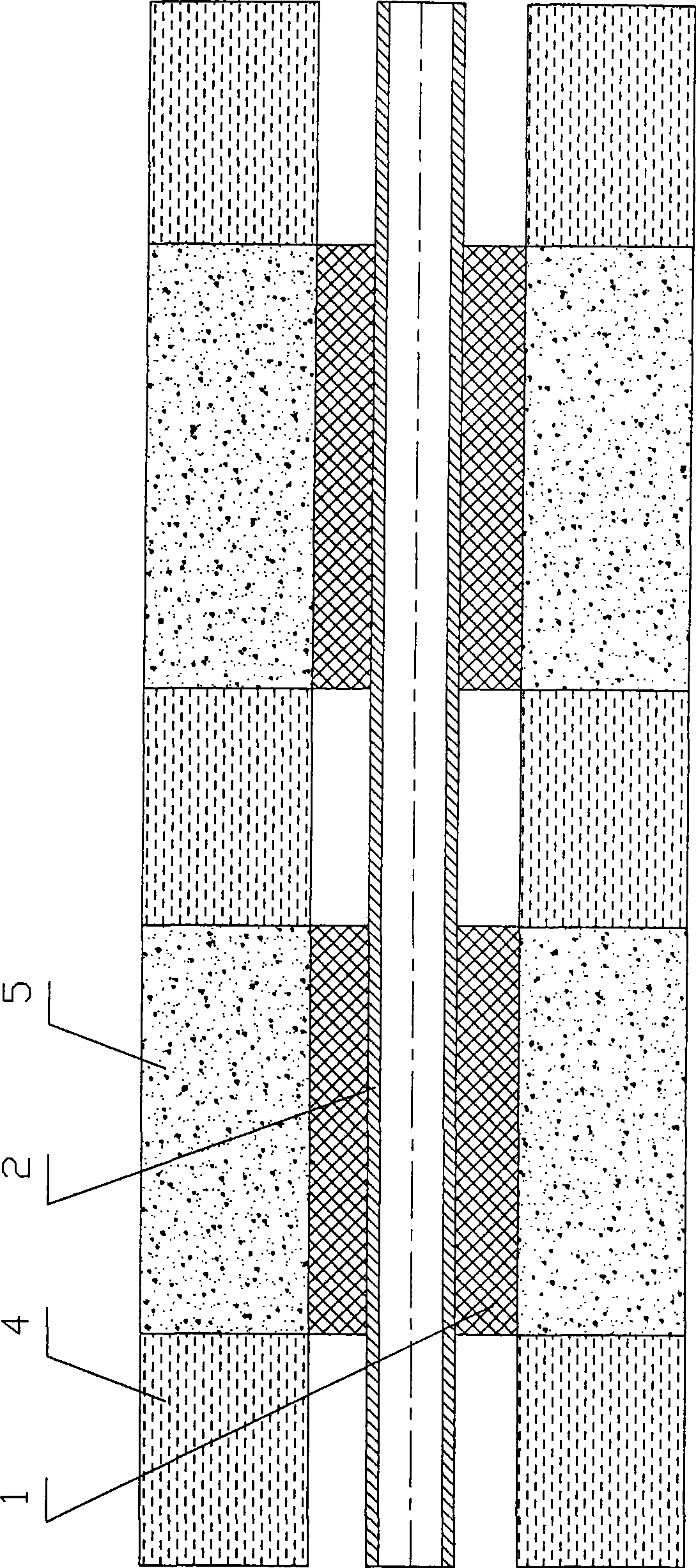

Embodiment 2

[0031] The steps of embodiment two:

[0032] as attached figure 2 As shown, the other steps are as described in Example 1, except that the setting position of the packer 1 in step 3 is the oil-gas interval 5, the length of the packer 1 exceeds the length of the oil-gas interval 5, and it is ensured that both its upper and lower ends enter into the oil-gas interval. The upper and lower non-oil and gas intervals 4 adjacent to the layer 5, and the length of the packer 1 should not exceed the length of a single casing, and the upper and lower ends should be enough for the position of the casing on and off, and the packer 1 should be cemented. The packed packer separates the oil-gas zone 5 from the non-oil-gas zone 4 .

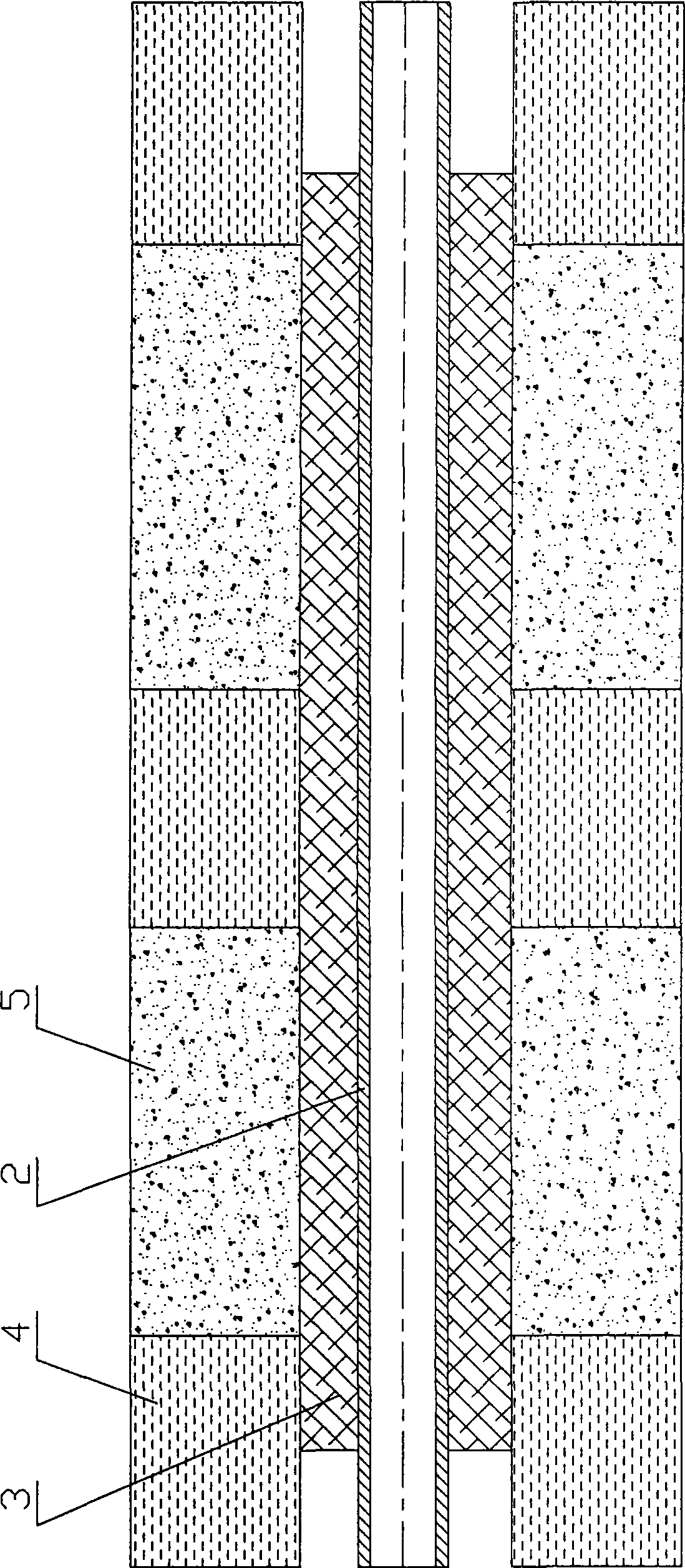

Embodiment 3

[0033] The steps of embodiment three:

[0034] Such as image 3 As shown, other steps are as in Example 1. The packer uses cement slurry to fill the long rubber cartridge packer 3, and after the cement slurry is solidified, perforation is performed at the position of the oil and gas layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com