Beneficiation method for complex sulphide lead-zinc ore containing arsenic

A technology of arsenic lead sulfide and ore dressing method, applied in flotation, solid separation, etc., can solve the problems of reducing arsenic grade in concentrate and increasing economic benefits, achieve good promotion and application value, avoid serious pollution, and reduce lime consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

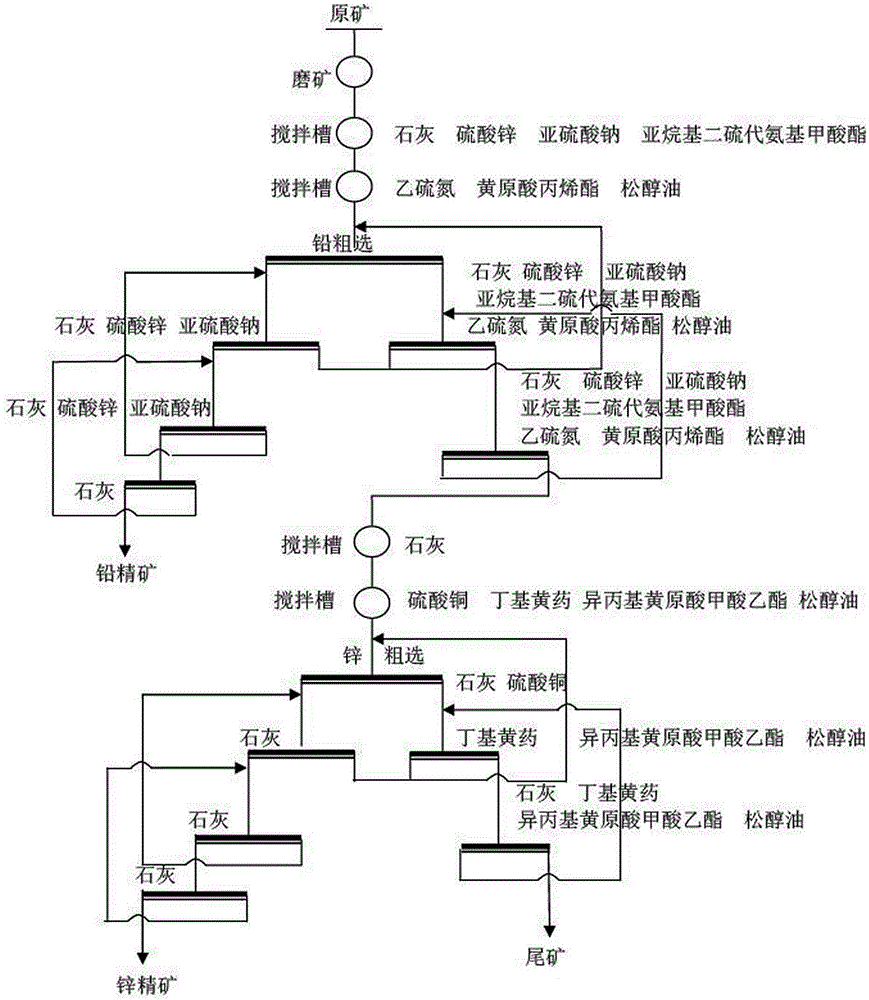

Method used

Image

Examples

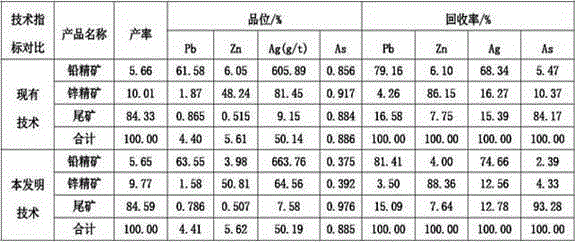

Embodiment 1

[0050] The main metal minerals in a lead-zinc-silver polymetallic ore are galena, sphalerite, pyrite and arsenopyrite, and their oxides are less. The intercalation relationship between metal minerals in the ore is relatively complex, and the ore is mostly produced in the form of massive, dense massive, lumpy and disseminated. The disseminated particle size of galena and sphalerite is mainly coarse-grained intercalation, and the intercalation relationship between the two is relatively close, and there is a phenomenon of mutual wrapping. Sphalerite coexists with galena, pyrite, and arsenopyrite, and a small amount is wrapped in massive galena in the form of broken spots and residual nuclei, or it is fine-grained and star-pointed with galena and a small amount of other The sulfides are embedded in the gangue together. The arsenopyrite contained in the ore is well crystallized, and is replaced by sphalerite and pyrite, and some arsenopyrite is distributed in the cracks of sphaler...

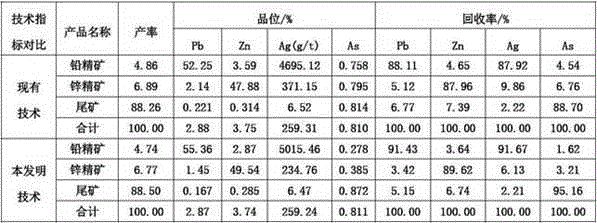

Embodiment 2

[0064] There are many kinds of metal minerals in a certain lead-zinc ore, among which the main metal minerals are galena, pyrite, sphalerite and arsenopyrite, and the content of other metal minerals is small; the non-metal minerals are mainly quartz and kaolin. The main recovered elements are lead, zinc and silver.

[0065] The galena and sphalerite in the ore are distributed in coarse grains, and the galena is distributed in the gangue minerals in the form of other shapes, irregular shapes and aggregates in the ore, showing a disseminated structure. Galenite is mostly metasomatized with pyrite, arsenopyrite and sphalerite, presenting a metasomatized corrosion structure. Galena contains a small amount of pyrite particles, and galena is filled and cemented along the arsenopyrite fractures, showing a vein-like structure. At the same time, galena is contained in pyrite, poisonous ore and flash in zinc mines. It can be seen that galena is closely related to pyrite, arsenopyrite ...

Embodiment 3

[0080] The metal minerals in a lead-zinc ore are pyrite, sphalerite, galena, arsenopyrite, pyrrhotite, and a small amount of lead alum, chalcopyrite, etc.; gangue minerals mainly include diopside, quartz, Wollastonite, fluorite, actinolite, carbonate, etc., and some argillaceous minerals.

[0081] In the ore, galena is mainly produced in other shapes and aggregates, mainly coarse and fine particles, and a small amount of fine particles are distributed in the gaps and cracks of gangue minerals and gangue mineral particles. Galena is closely related to sphalerite, pyrite, and arsenopyrite. The former accounts for the latter three, and some of them wrap each other, but the particles are coarser; the oxidation of galena in the ore is stronger than that of sphalerite. See To the secondary copper orchid, lead vitriol replaces galena, forming a film-like reaction edge structure. The silver minerals in the ore include argentite and native silver, galena is the main carrier mineral of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com