Beneficiation method for replacing sodium cyanide floating lead zinc to difficultly select ore

A technology of flotation lead-zinc and ore dressing method, which is applied in flotation, solid separation, etc., and can solve problems such as failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

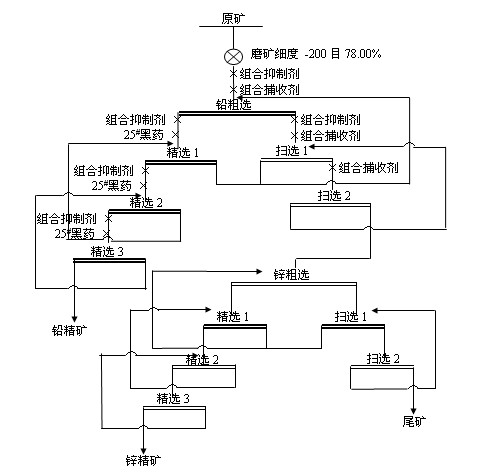

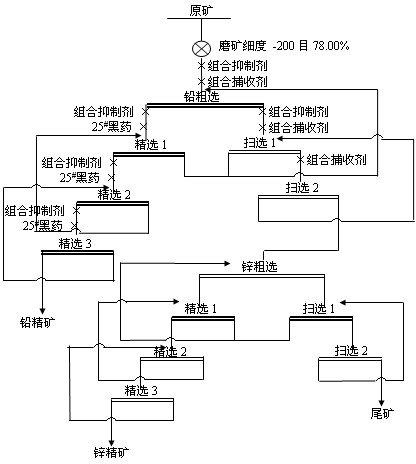

Image

Examples

Embodiment 1

[0069] The ore is selected from the northern Baoshan mine in Hunan:

[0070] (1) Grinding: Grinding the raw ore to a fineness of less than 0.074mm accounts for 78% of the whole raw ore;

[0071] (2) Lead priority flotation: adopt the method of one-time roughing, three-time beneficiation, two-time sweeping, and sequential return to obtain lead concentrate;

[0072] Wherein Na is added before lead roughing flotation 2 S 100g / t, sodium carbonate 200g / t, ZnSO 4 1300g / t and Na 2 SO 3 300g / t combined inhibitor, add MB xanthate 50 g / t, ethyl xanthate 20g / t and No. 25 black medicine 20g / t combined collector, add No. 2 oil 60 g / t;

[0073] Add sodium carbonate 200g / t, ZnSO 4 500g / t and Na 2 SO3 200g / t combined inhibitor, add MB xanthate 20 g / t, ethyl xanthate 10g / t and No. 25 black medicine 10g / t combined collector;

[0074] Add the combined collector of MB xanthate 20 g / t, ethyl xanthate 10 g / t and No. 25 black medicine 10 g / t before the second sweep of lead flotation;

[0075...

Embodiment 2

[0079] The ore is selected from Baoshan Western Mine 1 in Hunan:

[0080] (1) Grinding: Grinding the raw ore to a fineness of less than 0.074mm accounts for 78% of the whole raw ore;

[0081] (2) Lead priority flotation: adopt the method of one-time roughing, three-time beneficiation, two-time sweeping, and sequential return to obtain lead concentrate;

[0082] Among them, Na is added before the lead roughing flotation 2 S200g / t, sodium hydroxide 600g / t, ZnSO 4 1300g / t and Na 2 SO 3 400g / t combined inhibitor, add MB xanthate 30g / t, ethionazol 30g / t and No. 25 black drug 20g / t combined collector, add No. 2 oil 50 g / t;

[0083] Add sodium hydroxide 200g / t, ZnSO before the first sweep of lead flotation 4 600g / t and Na 2 SO 3 200g / t combined inhibitor, add MB xanthate 12 g / t, ethiazide 12g / t and No. 25 black drug 20g / t combined collector, add No. 2 oil 20 g / t;

[0084] Add MB xanthate 10g / t, ethiazide 10g / t and No. 25 black medicine 20g / t combined collector before the seco...

Embodiment 3

[0090] The ore is selected from Baoshan placer in Hunan

[0091] (1) Grinding: Grinding the raw ore to a fineness of less than 0.074mm accounts for 78% of the whole raw ore;

[0092] (2) Lead priority flotation: adopt the method of one-time roughing, three-time beneficiation, two-time sweeping, and sequential return to obtain lead concentrate;

[0093] Among them, Na is added before the lead roughing flotation 2 S 200g / t, sodium hydroxide 800g / t, ZnSO 4 1300g / t and Na 2 SO 3 500g / t combined inhibitor, the combined collector added is ethiazide 60g / t, butylamine black drug 10g / t and No. 25 black drug 40g / t;

[0094] Add sodium hydroxide 400g / t, ZnSO 4 750g / t and Na 2 SO 3 300g / t combined inhibitor, add 20g / t ethyl dithiazide, 20g / t No. 25 black medicine combined collector;

[0095] Before the second lead scavenging and flotation, the combined collectors are 20g / t of ethionazol and 20g / t of No. 25 black medicine;

[0096] (3) Priority flotation of zinc from floating lead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com