Viscosity-controllable aqueous lubricating liquid and application

A water-based lubricating fluid and viscosity technology, applied in the field of lubricating fluids, can solve the problems of insoluble silicate and borate, high cost of molybdate and inapplicability, etc. The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

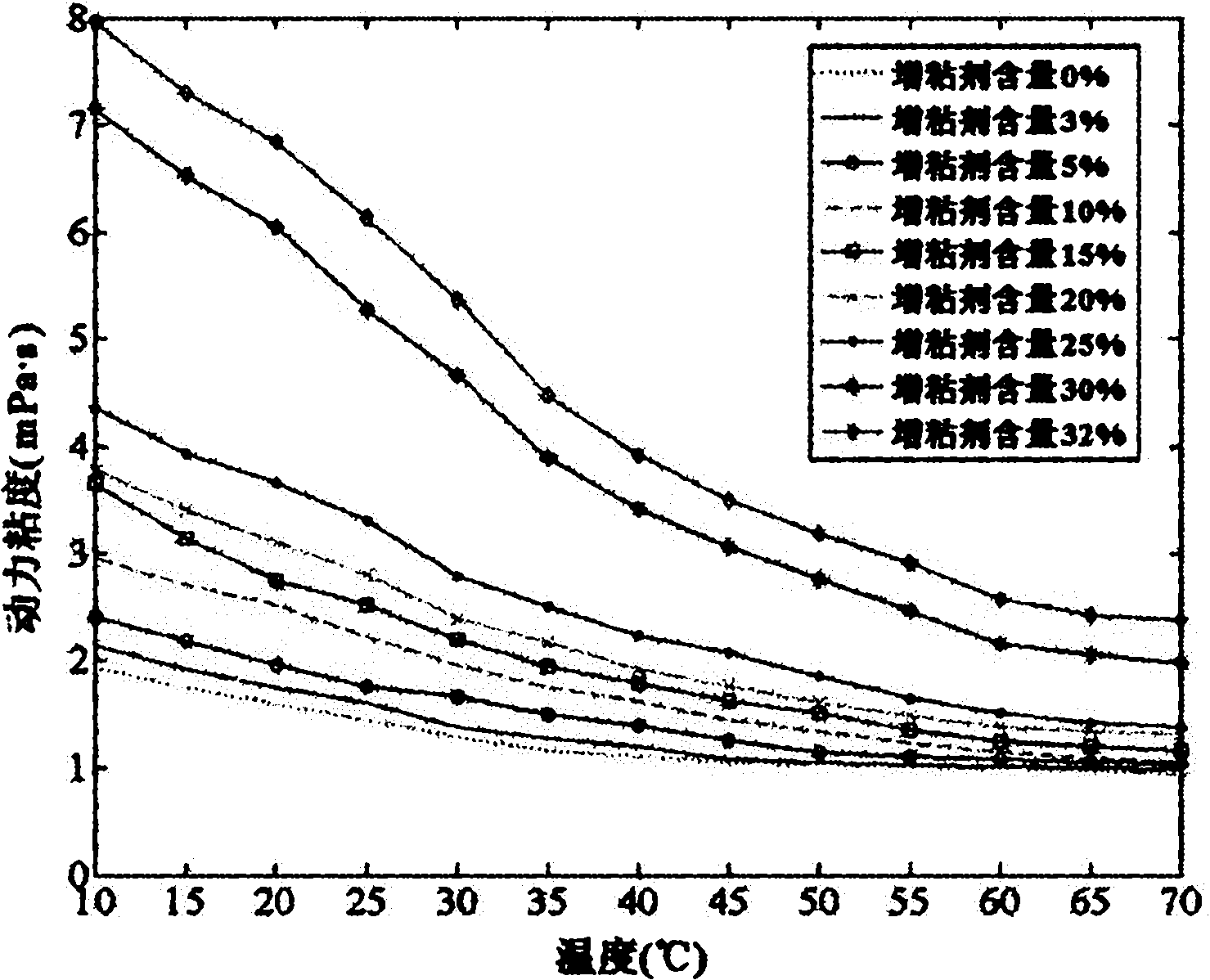

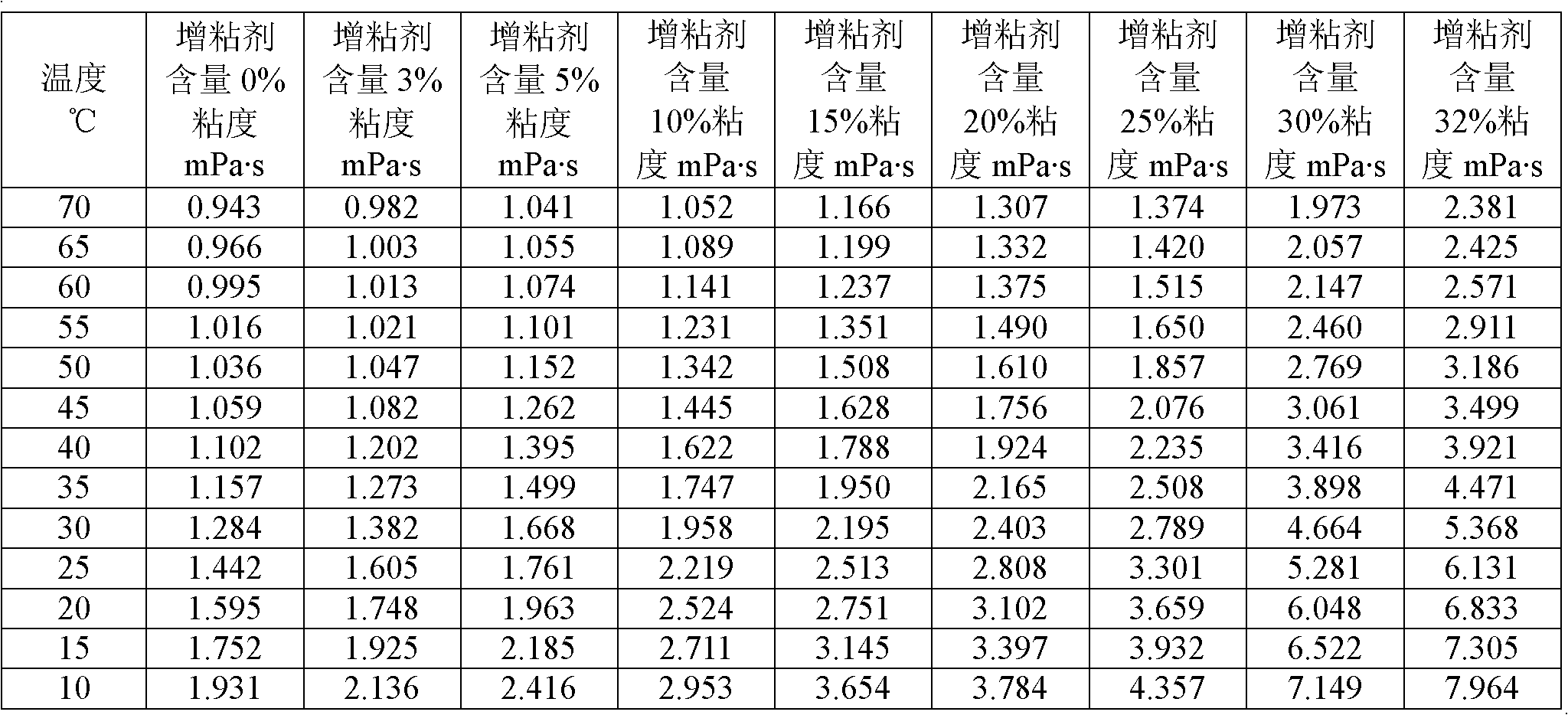

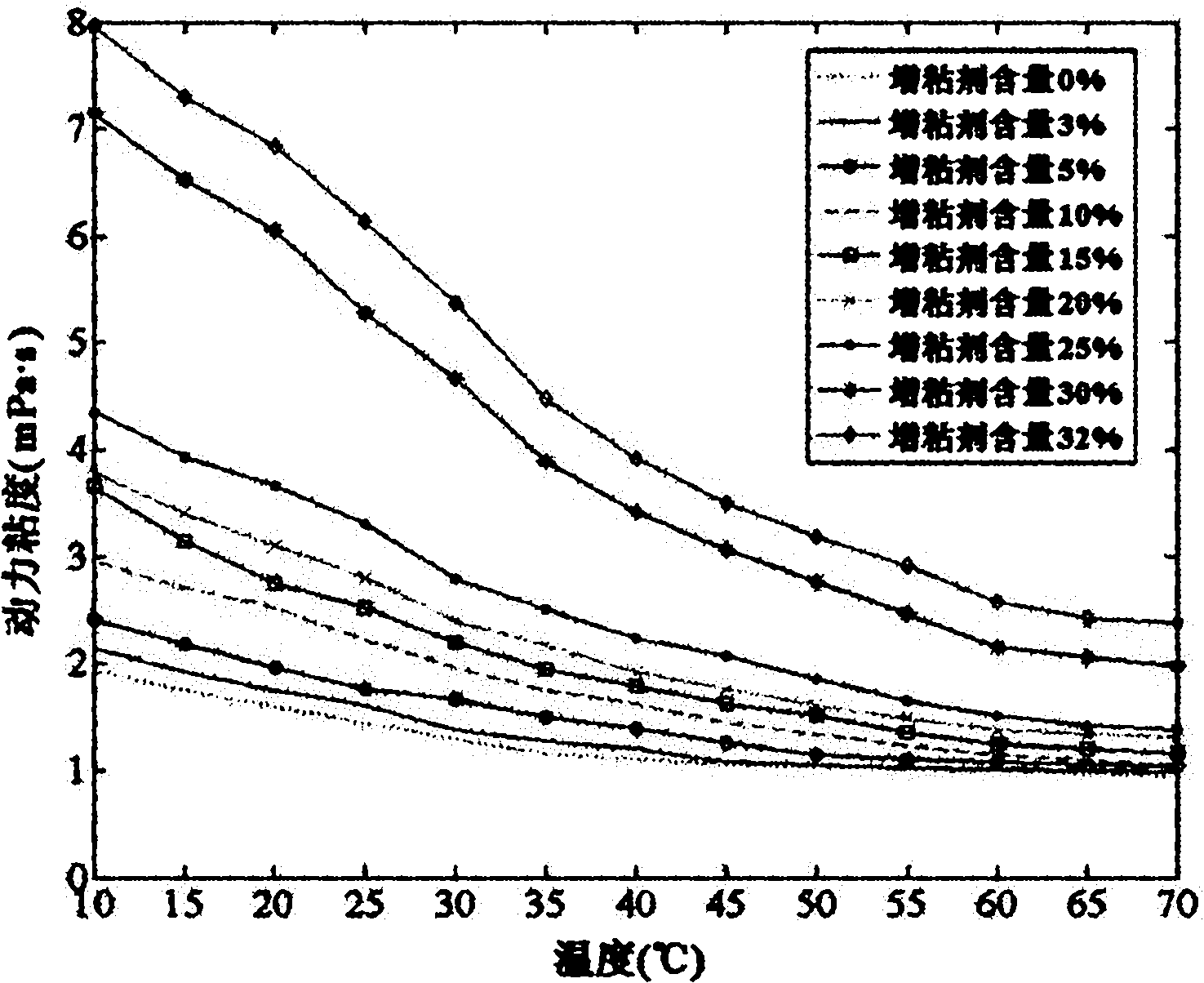

Image

Examples

Embodiment 1

[0027] Embodiment 1: When it is suitable for lubricating sliding bearings, the method of use: when the lubricating fluid is suitable for lubricating sliding bearings, its usage is similar to ordinary lubricating oil. If the sliding bearing is a dynamic pressure sliding bearing, the method of immersing the friction pair in lubricating fluid can be used. When the main shaft rotates, due to the dynamic pressure effect, the lubricating liquid can form a bearing liquid film to ensure the normal and stable operation of the main shaft; if the sliding bearing is static pressure or For the form of dynamic and static pressure lubrication, refer to the specific sliding bearing and restrictor structure, inject a certain pressure into the sliding bearing system, form a bearing liquid film in the bearing gap, and ensure the normal and stable operation of the spindle.

[0028] Prepare 82.6kg of high-purity water in the high-purity water machine, and prepare 8kg of triethanolamine borate, 9kg ...

Embodiment 2

[0031] Embodiment 2: The method of use when it is suitable for hydrostatic guide rails: if it is used for open hydrostatic guide rails, the lubricating liquid enters the single-sided liquid chamber of the guide rail through the throttle at a certain pressure from the liquid pump, and floats the moving parts to make the guide rail When the surface moves, it is in a state of pure liquid friction and forms a bearing liquid film; if it is used in a closed static pressure guide rail, the lubricating liquid is passed through the restrictor by the liquid pump at a certain pressure, and enters multiple liquid chambers on each side of the guide rail to form a bearing liquid film , and ensure that the guide rail can still work normally under the two-way external load.

[0032] Prepare 39.5kg of high-purity water, 15kg of triethanolamine borate, 12kg of triethanolamine oleate, 1kg of triethanolamine sebacate, 32kg of ethylene glycol and 0.5kg of silicone defoamer, and then pour the above ...

Embodiment 3

[0034] Embodiment 3: Under the situation that each component of water-based lubricating fluid has been determined, test the antirust performance of the lubricating fluid, with reference to the national standard GB6144-85 (the regulation of the cutting fluid antirust performance test) as the test standard, adopt the monolithic method and The antirust performance of the lubricating fluid (experimental samples included several groups of lubricating fluids with different antirust ratios; in order to reduce the test time, a 5% diluted aqueous solution was used) was tested by lamination method. The specific test plan is as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com