High temperature resistant well-cementing spacer fluid and preparation method thereof

A spacer fluid and high temperature resistance technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor temperature resistance, solid phase particle settlement, slurry viscosity reduction, etc., and achieve good acid and alkali resistance , Improve rheology, reduce viscosity and shear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] According to the designed density of the spacer, it is prepared according to 100 parts by weight of fresh water, 2-8 parts by weight of suspending agent, 1-15 parts by weight of flushing agent, 2-10 parts by weight of diluent, and 25-400 parts by weight of weighting agent.

[0015] First weigh fresh water, add suspending agent at 4000rpm and stir for 3 minutes, and dissolve for 30 minutes; add diluent and weighting agent at 4000rpm and stir for 10 minutes; add rinse agent at a stirring speed of 2000rpm and stir for 1 minute to prepare the spacer.

[0016] In order to test the rheological properties of the spacer fluid system, a density of 1.2 ~ 2.5g / cm 3 A total of 6 density points of spacer fluid. The experimental method is as follows: at room temperature, after stirring for 20 minutes in an atmospheric thickener, test the rheology with a six-speed rotational viscometer. From the experimental results (as shown in Tables 1 and 2), the spacer fluid system at each densit...

Embodiment 2

[0022] Prepare by 100 parts by weight of fresh water, 7 parts by weight of suspending agent, 3 parts by weight of diluent, 5 parts by weight of flushing agent and 40 parts by weight of weighting agent.

[0023] First weigh 100 parts by weight of fresh water, add 7 parts by weight of suspending agent at 4000rpm and stir for 3 minutes, dissolve for 30 minutes; add 3 parts by weight of diluent and 40 parts by weight of weighting agent at 4000rpm and stir for 10 minutes; Add 5 parts by weight of flushing agent and stir for 1 minute to prepare an isolation solution.

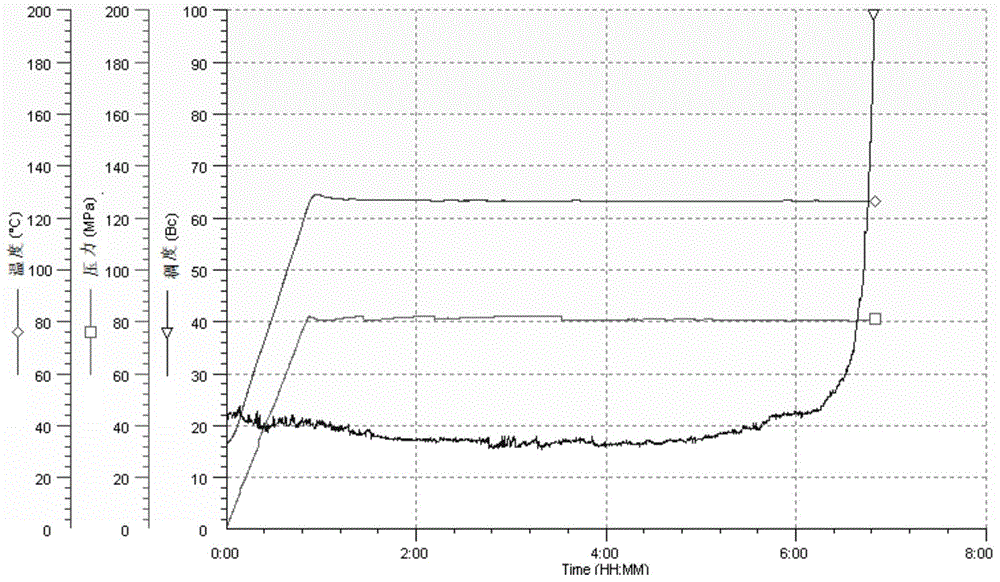

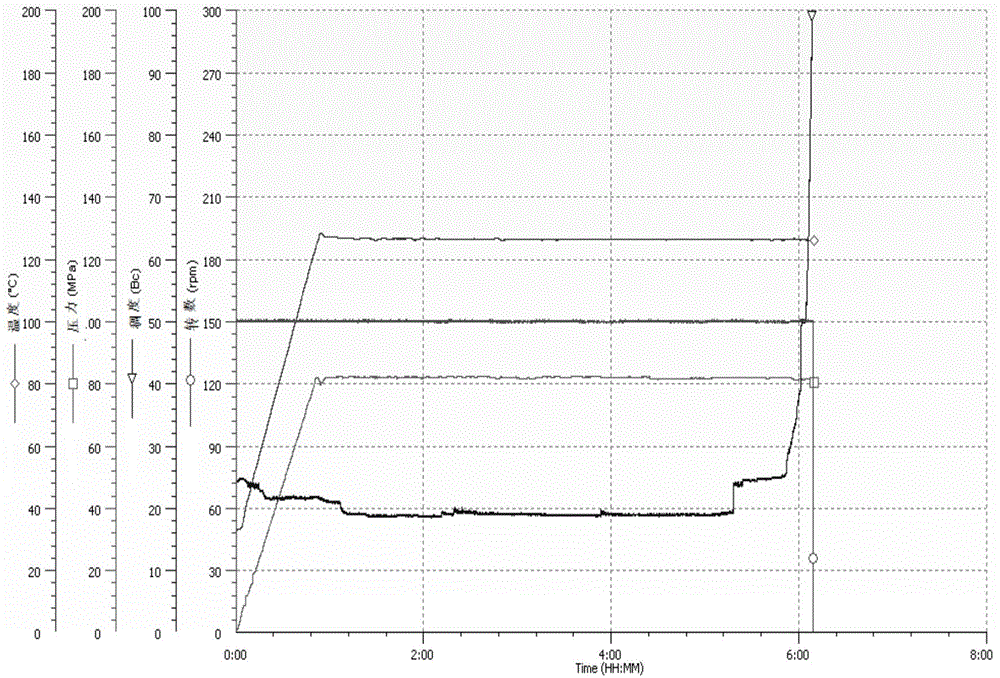

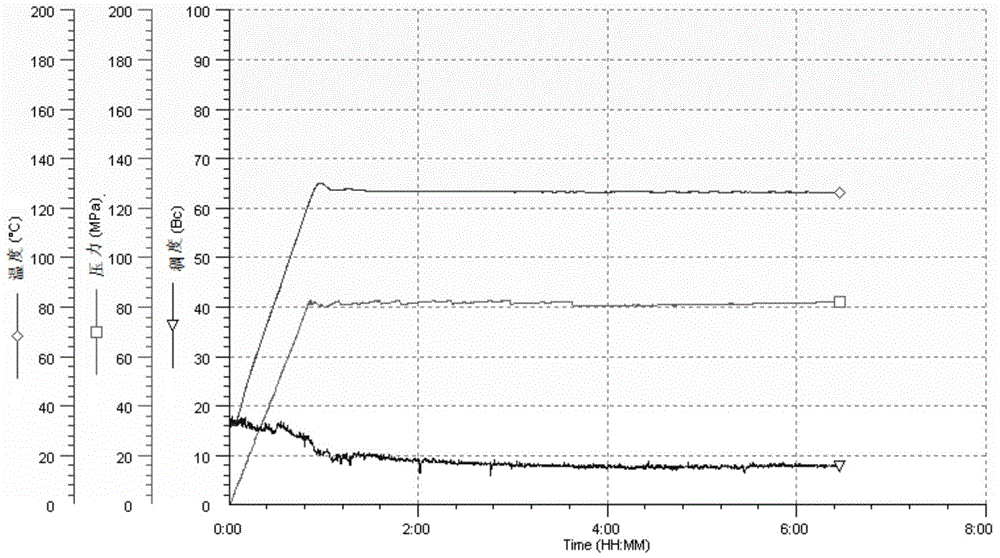

[0024] The measured spacer density is 1.3g / cm 3 , the temperature resistance test method of the spacer liquid system is as follows: ①The temperature is lower than 90°C, at the experimental temperature, after the spacer liquid is stirred in the normal pressure thickener for 20 minutes, test its rheology with a six-speed rotational viscometer; ② If the temperature is higher than 90°C, first raise the high-temperature r...

Embodiment 3

[0029] It is prepared according to 100 parts by weight of fresh water, 4 to 7 parts by weight of suspending agent, 4 parts by weight of diluent, 5 parts by weight of flushing agent and 80 parts by weight of weighting agent.

[0030] First weigh 100 parts by weight of fresh water, add 4 to 7 parts by weight of suspending agent at 4000rpm and stir for 3 minutes, dissolve for 30 minutes; add 4 parts by weight of diluent and 80 parts by weight of weighting agent at 4000rpm and stir for 10 minutes; Add 5 parts by weight of flushing agent at 2000 rpm and stir for 1 minute to prepare an isolation solution.

[0031] In order to test the influence of the amount of suspending agent on the rheological properties of the spacer fluid, a spacer fluid system with the same density and the same composition of admixtures was prepared. It can be seen from the experimental results (as shown in Table 5) that the amount of suspending agent has a good linear relationship with the plastic viscosity a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com