Texture paint and preparation method thereof

A technology of textured paint and mass percentage content, applied in the field of textured paint, can solve the problems of easy sand falling off in batch scraping, short open time, and low adhesion, and achieve good water retention, long open time, and high adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

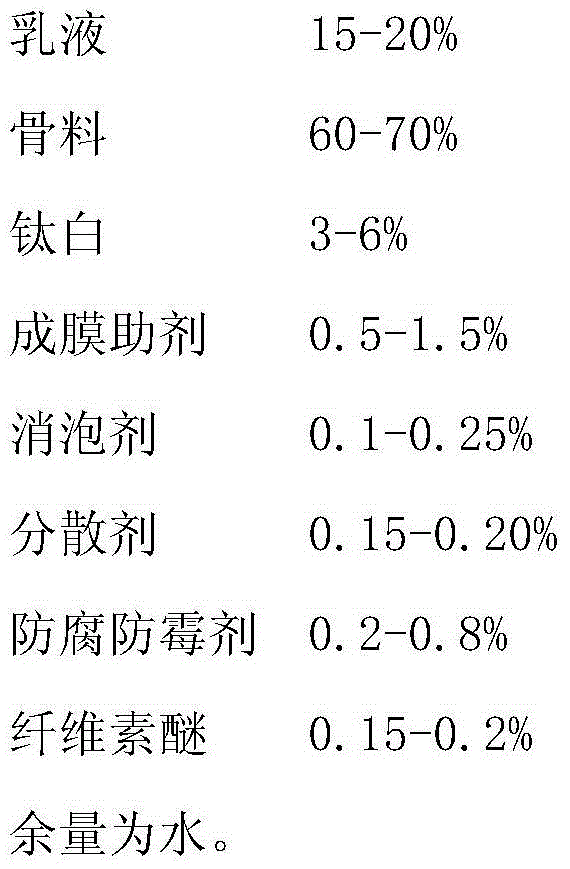

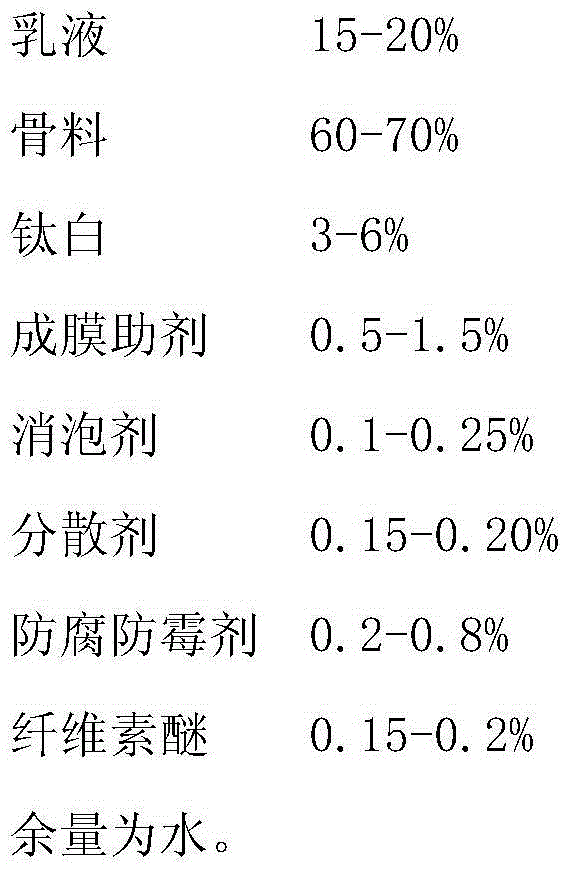

[0024] A kind of texture paint, its component and mass percentage are:

[0025] AC-261 emulsion and D-68 emulsion: 20%;

[0026] 325 mesh special white stone powder: 60%;

[0027] Titanium dioxide: 6%;

[0028] Lauryl alcohol ester: 1.5%;

[0029] A203E type defoamer: 0.25%;

[0030] Polyacrylic acid sodium salt dispersant: 0.20%;

[0031] Rohm and Haas antifungal agent-363 and Kathon LEX fungicide mixture: 0.8%;

[0032] Hydroxypropyl methylcellulose: 0.20%;

[0033] Thickener TT-615: 0.60%;

[0034] The remainder is water;

[0035] Among them, the mass ratio of AC-261 emulsion and D-68 emulsion is: 2:1; the mass ratio of the two components in Rohm and Haas antifungal agent-363 and Kathon LEX fungicide mixture is 3:2.

[0036] A method for preparing the above-mentioned texture paint, comprising the steps of:

[0037] (1) After adding water to the tank, add anti-corrosion and anti-fungal agents and defoamers; start anchor stirring and stir at 300-500RPM for 1-2 minute...

Embodiment 2

[0042] A kind of texture paint, its component and mass percentage are:

[0043] AC-261 emulsion and D-68 emulsion: 15%;

[0044] 60 mesh snow white sand: 70%;

[0045] R-258 titanium dioxide: 5%;

[0046] Lauryl alcohol ester: 1.5%;

[0047] A203E type defoamer: 0.15%;

[0048] Polyacrylic acid sodium salt dispersant: 0.20%;

[0049] Mixture of Rohm and Haas Antifungal Agent-363, Kathon LEX fungicide and carbendazim powder: 0.5%;

[0050] Hydroxyethyl methylcellulose: 0.15%;

[0051] The remainder is water;

[0052] Wherein, the mass ratio of AC-261 emulsion and D-68 emulsion is: 1.5:1; The mass ratio of three kinds of compositions in the mixture of Rohm and Haas antifungal agent-363, Kathon LEX fungicide and carbendazim former powder is : Rohm and Haas antifungal agent-363: Kathon LEX fungicide: carbendazim powder = 4:3:3.

[0053] A method for preparing the above-mentioned texture paint, comprising the steps of:

[0054] (1) After adding water to the tank, add anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com