Manufacturing method for weaving single-width gradually-changed jacquard fabric by using double-handle lifting jacquard machine

A technology of jacquard fabric and manufacturing method, which is applied in the direction of excavation fabric, fabric, embossed fabric, etc., can solve the problem that single-width weave can not be manufactured by double-hanging jacquard machine, and achieves the improvement of visual impact and artistic sense. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] like Figure 3 to Figure 12 Shown, a kind of manufacturing method of weaving single-width gradient jacquard fabric with double handle jacquard machine comprises the following steps:

[0043] S1. Select a double-handle jacquard machine, and determine the number of main grain stitches to be 9600;

[0044] S2. Determine the apparent warp and weft density of the finished fabric according to the thickness and weave type of the warp and weft yarns;

[0045] S3. Determine the size of the pattern, so that the number of warp loops of the pattern is half of the number of stitches in the main pattern, i.e. 4800, and the weft loop can be designed as required;

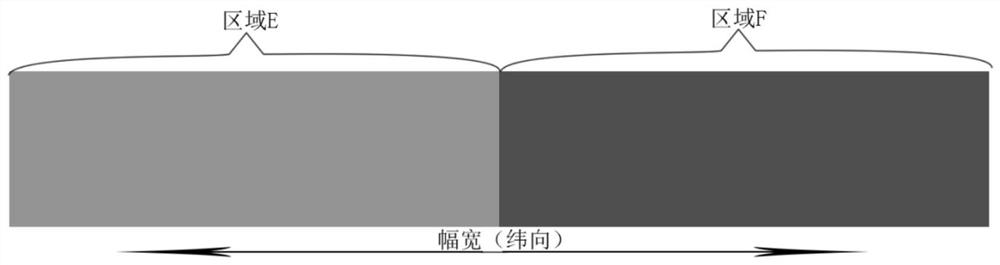

[0046] S4. Designing a pattern, making the pattern continuous in four directions, and making the width direction of the pattern connect to two positions, and designing the color to form a single gradient effect;

[0047] S5. Determine the permutation, such as image 3 and Figure 4 Shown, the warp yarn is divided into th...

Embodiment 2

[0060] The difference between this embodiment and the first embodiment is that the weft yarn has only three systems, including weft yarn A, weft yarn B and weft yarn C. Tissue 4 was not included in the tissues of regions E and F.

[0061] In the present invention, without changing the original packaging, the square continuous pattern is connected to two positions, and the color design is carried out. The color design has a gradient effect. According to the color change, dark and light colors are used as the colors of the warp yarns, and the warps are arranged. , the warp yarn is divided into two systems, the first system is dark warp yarn, the second system is arranged in sections of dark and light colored warp yarn, and the weft yarn has at least three systems, of which two weft yarn systems are the same dark color and light color as the warp yarn, and the other The first weft yarn system is a transitional color between dark and light colors. The color of the Italian craftsma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com