Preparation method of silicon dioxide used for tooth paste

A silicon dioxide and toothpaste technology, applied in the direction of silicon oxide, etc., can solve the problems of increased dust labor cost, the abrasive amount and thickening performance of toothpaste abrasives cannot meet the requirements for use at the same time, and cannot be used as a friction agent, etc. thick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

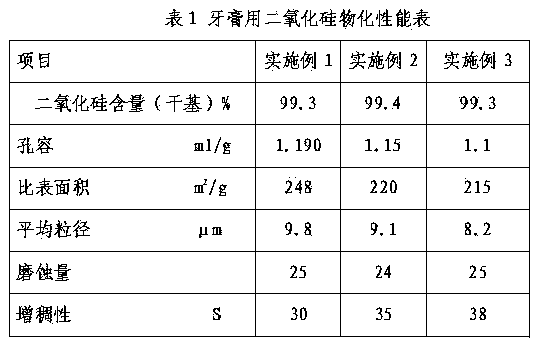

Embodiment 1

[0028] (1) Add water to the raw material sodium silicate to make 500g of 15%wt sodium silicate solution based on silicon dioxide, add water to sulfuric acid to make 225g of 20%wt sulfuric acid aqueous solution, first add 112.5g of sulfuric acid aqueous solution to the reaction kettle, At room temperature, add sodium silicate solution at a rate of 150 g / min, and stop adding sodium silicate when the pH of the reaction end point is 7. Raise the temperature to 80°C for 1 hour.

[0029] (2) Add the remaining sodium silicate solution to step (1), heat up to 80°C, then add sulfuric acid aqueous solution at a rate of 150g / min, stop adding acid until the pH of the reaction end point is 4, stir and keep warm for 30 minutes

[0030] (3) Filter and wash the reaction material until the sodium ion content of the product is below 0.2%wt, and beat the filter cake for 1 hour.

[0031] (4) Dehydration and drying by flash drying; the dried product is crushed to an average particle size of 10 mi...

Embodiment 2

[0034] (1) Add water to the raw material sodium silicate to form 500g of 18%wt sodium silicate solution based on silicon dioxide, add water to sulfuric acid to prepare 270g of 20%wt sulfuric acid aqueous solution, first add 135g of sulfuric acid aqueous solution to the reaction kettle, At room temperature, add sodium silicate solution at a rate of 200 g / min, and stop adding sodium silicate when the pH of the reaction end point is 7. Raise the temperature to 80°C for 1 hour.

[0035] (2) Add the remaining sodium silicate solution into step (1), raise the temperature to 80°C, then add sulfuric acid aqueous solution at a rate of 200g / min, stop adding acid until the pH of the reaction end point is 4, stir and keep warm for 30 minutes

[0036] (3) Filter and wash the reaction material until the sodium ion content of the product is below 0.2%wt, and beat the filter cake for 1 hour.

[0037] (4) Dehydration and drying by flash drying; the dried product is crushed to an average parti...

Embodiment 3

[0039] (1) Add water to the raw material sodium silicate to prepare 500g of 20%wt sodium silicate solution based on silicon dioxide, add water to sulfuric acid to prepare 200g of 30%wt sulfuric acid aqueous solution, first add 100g of sulfuric acid aqueous solution to the reaction kettle, At room temperature, add sodium silicate solution at a rate of 300 g / min, and stop adding sodium silicate when the pH of the reaction end point is 7. Raise the temperature to 70°C for 2 hours.

[0040] (2) Add the remaining sodium silicate solution into step (1), raise the temperature to 70°C, then add sulfuric acid aqueous solution at a rate of 300g / min, stop adding acid until the reaction end point is PH4, stir and keep warm for 30 minutes

[0041] (3) Filter and wash the reaction material until the sodium ion content of the product is below 0.2%wt, and beat the filter cake for 1 hour.

[0042] (4) Dehydration and drying by flash drying; the dried product is crushed to an average particle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com