Water-base lubricant and preparation method thereof

A lubricating oil and water-based technology, which is applied in the field of lubricating oil, can solve the problems of non-biodegradable waste oil and pollute the environment, and achieve the effect of increasing the maximum non-jamming load and improving the lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

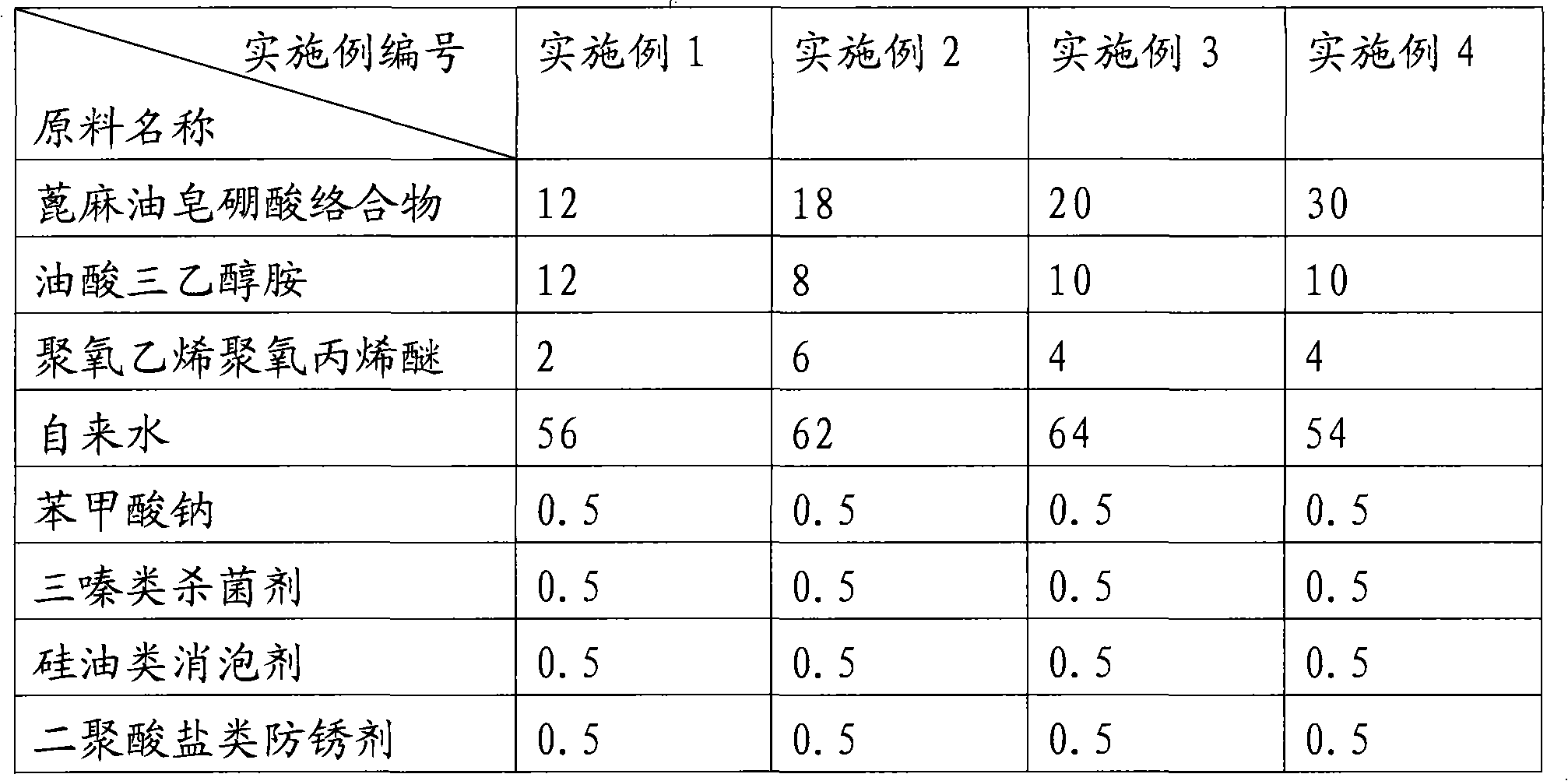

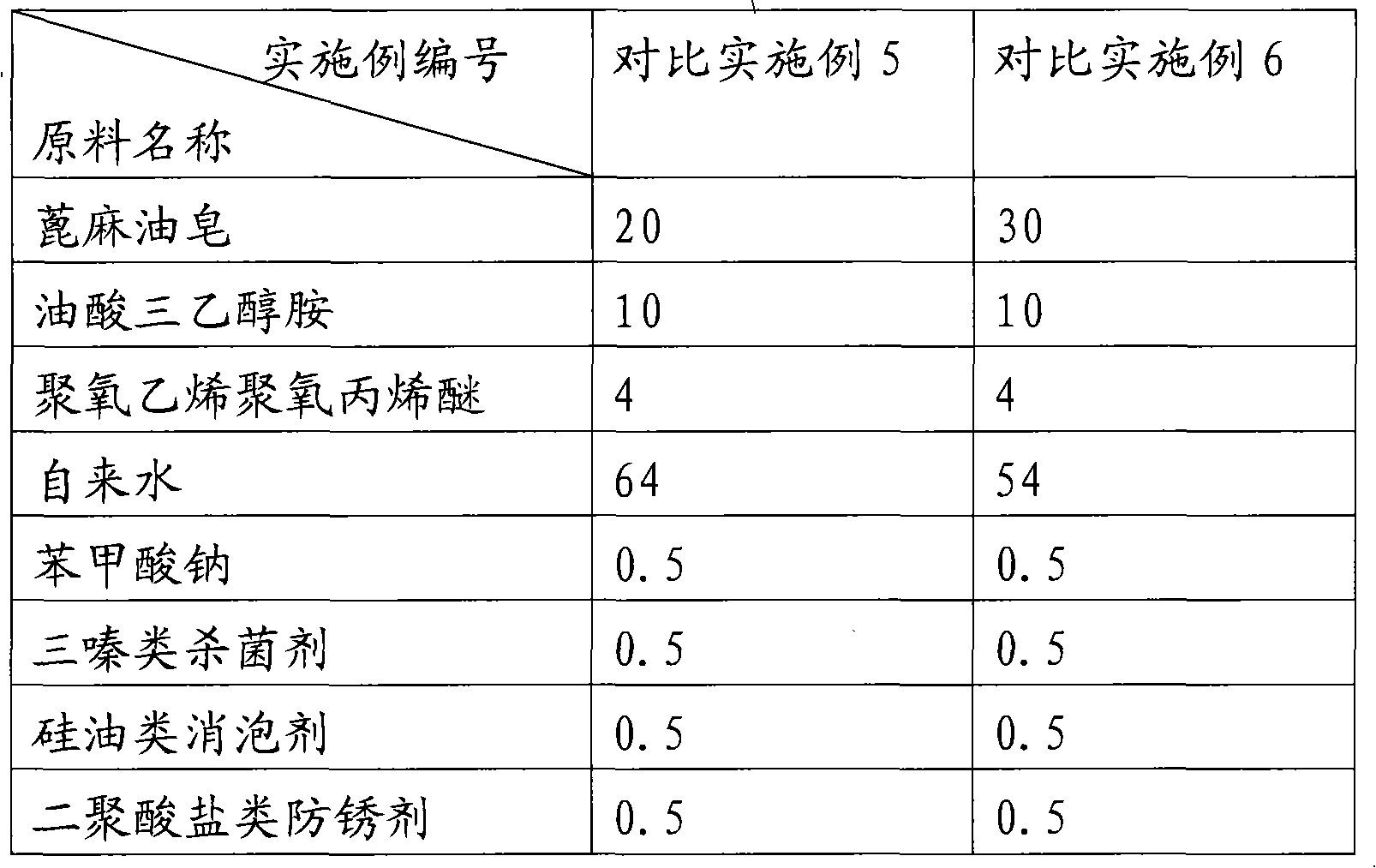

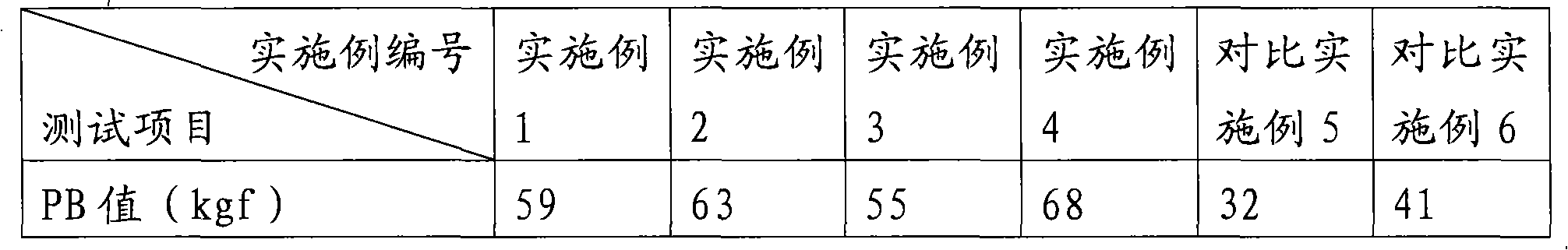

Examples

preparation example Construction

[0035] First introduce the preparation method of castor oil soap boric acid complex:

[0036] a) Pump the measured castor oil and tap water into the reaction kettle, stir, and heat with heat transfer oil, and the temperature is controlled between 65°C and 95°C;

[0037] b) Slowly add triethanolamine into the reaction kettle, monitor the appearance of the mixture in the reaction kettle in real time, and stop adding triethanolamine when the appearance of the mixture reaches transparent and clear, which is the end point of the saponification reaction;

[0038] c) adding boric acid, controlling the reaction temperature at 80°C to 90°C, and the pH value at 7.5 to 8.5, and the production liquid after the reaction is a transparent castor oil soap boric acid complex solution.

[0039] Then introduce the preparation method of oleic acid triethanolamine:

[0040] a) pump metered oleic acid and triethanolamine into the reactor, stir and heat;

[0041] b) When the temperature reaches 12...

Embodiment 1

[0044] a) Add the solution of castor oil soap boric acid complex and triethanolamine oleate into the reaction kettle, stir evenly, and control the temperature at 45°C;

[0045] b) adding water, bactericide, defoamer, preservative and rust preventive to the reactor in sequence;

[0046] c) adding polyoxyethylene polyoxypropylene ether to adjust to a specified viscosity, and then obtaining a water-based lubricating oil.

Embodiment 2

[0048] a) Add the solution of castor oil soap boric acid complex and triethanolamine oleate into the reaction kettle, stir evenly, and control the temperature at 55°C;

[0049] b) adding water, bactericide, defoamer, preservative and rust preventive to the reactor in sequence;

[0050] c) adding polyoxyethylene polyoxypropylene ether to adjust to a specified viscosity, and then obtaining a water-based lubricating oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com