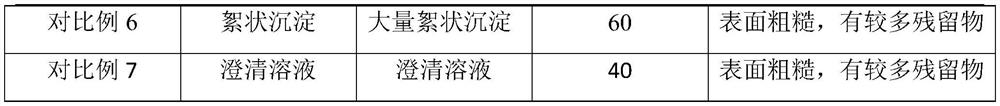

Patents

Literature

60results about How to "The effect remains the same" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anticorrossion antiwear ceramic paint

InactiveCN1325931AHigh hardnessImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyGlass fiber

An anticorrosion and antiwear ceramic paint is prepared from epoxy resin (28.5-35 wt.portions), dibutyl phthalate (3.75-6), mixed solvent of xyrene and n-butyl ester (20-24), gas-phase SiO2 (0.5-1) and ceramic powder (38-45) which contains TiO2 (3-6.3), Al2O3 (11.7-20) and Si3N4 (16-20.45). The weight ratio of main component to slidifying agent is (14.5-17):1. It can be directly applied to the surfaces of metal, glass fibre, plastic, or concrete with the advantages of high antiwear performance and adhesion, and thin and compact coated layer.

Owner:BEIJING UNIV OF CHEM TECH

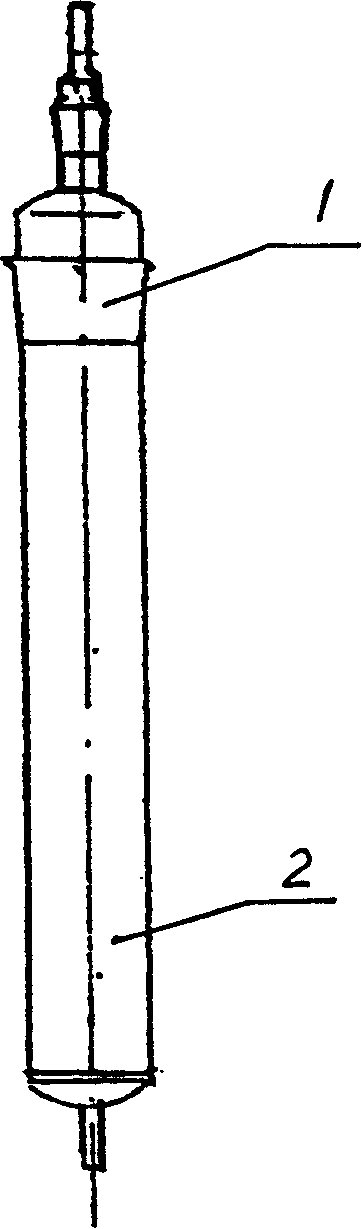

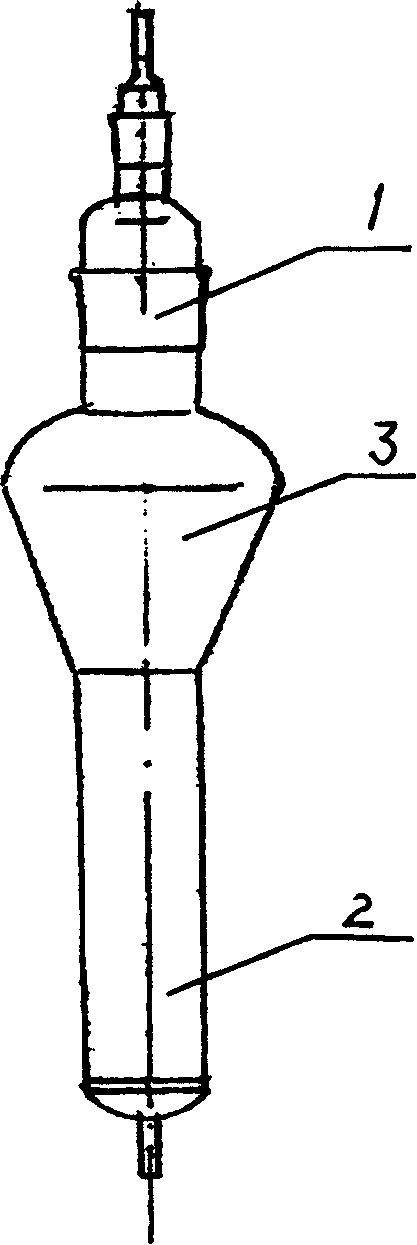

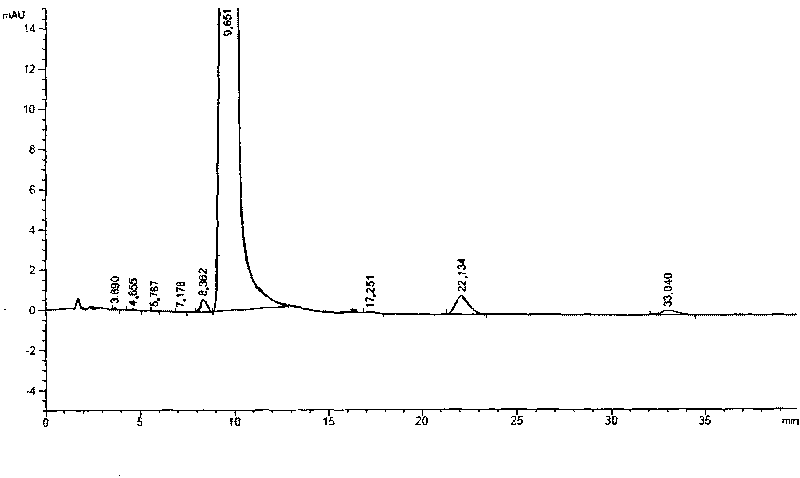

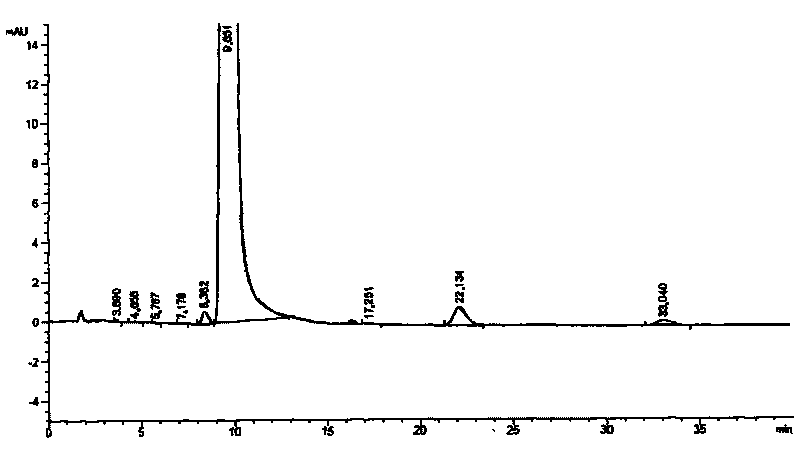

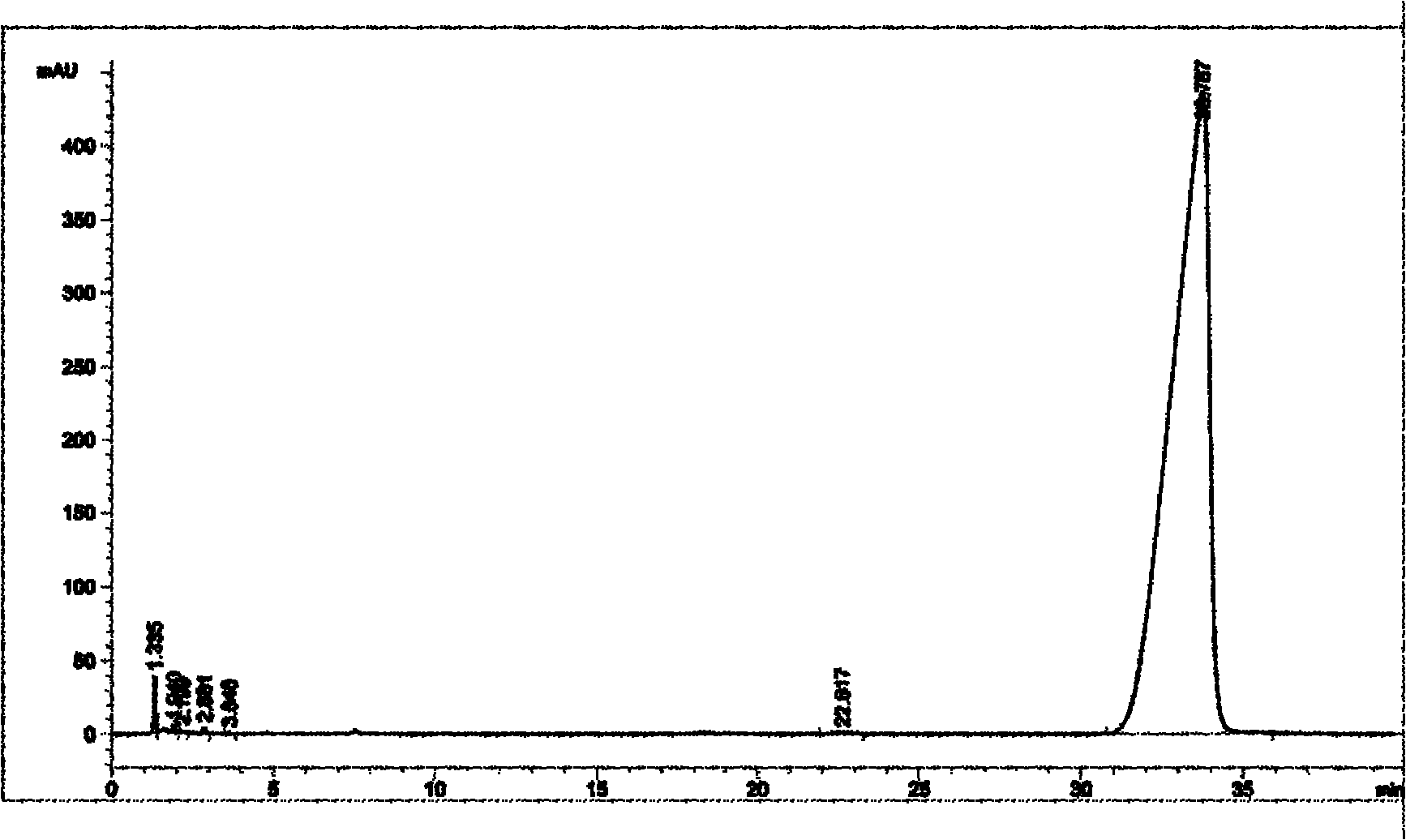

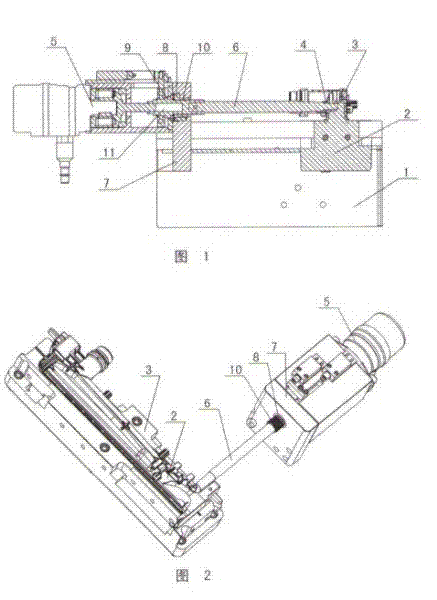

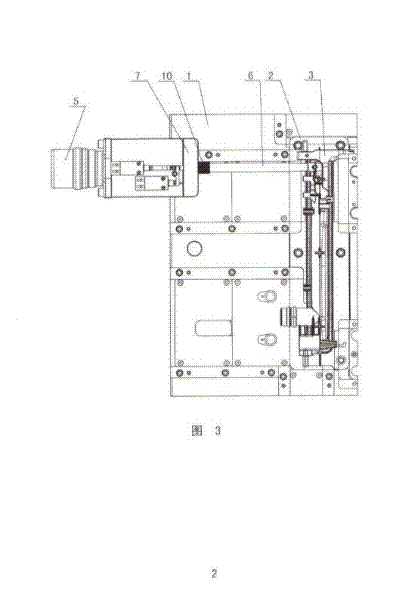

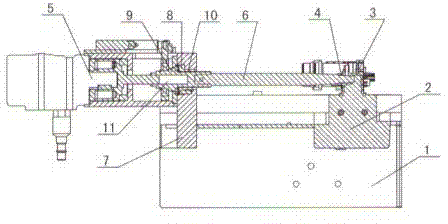

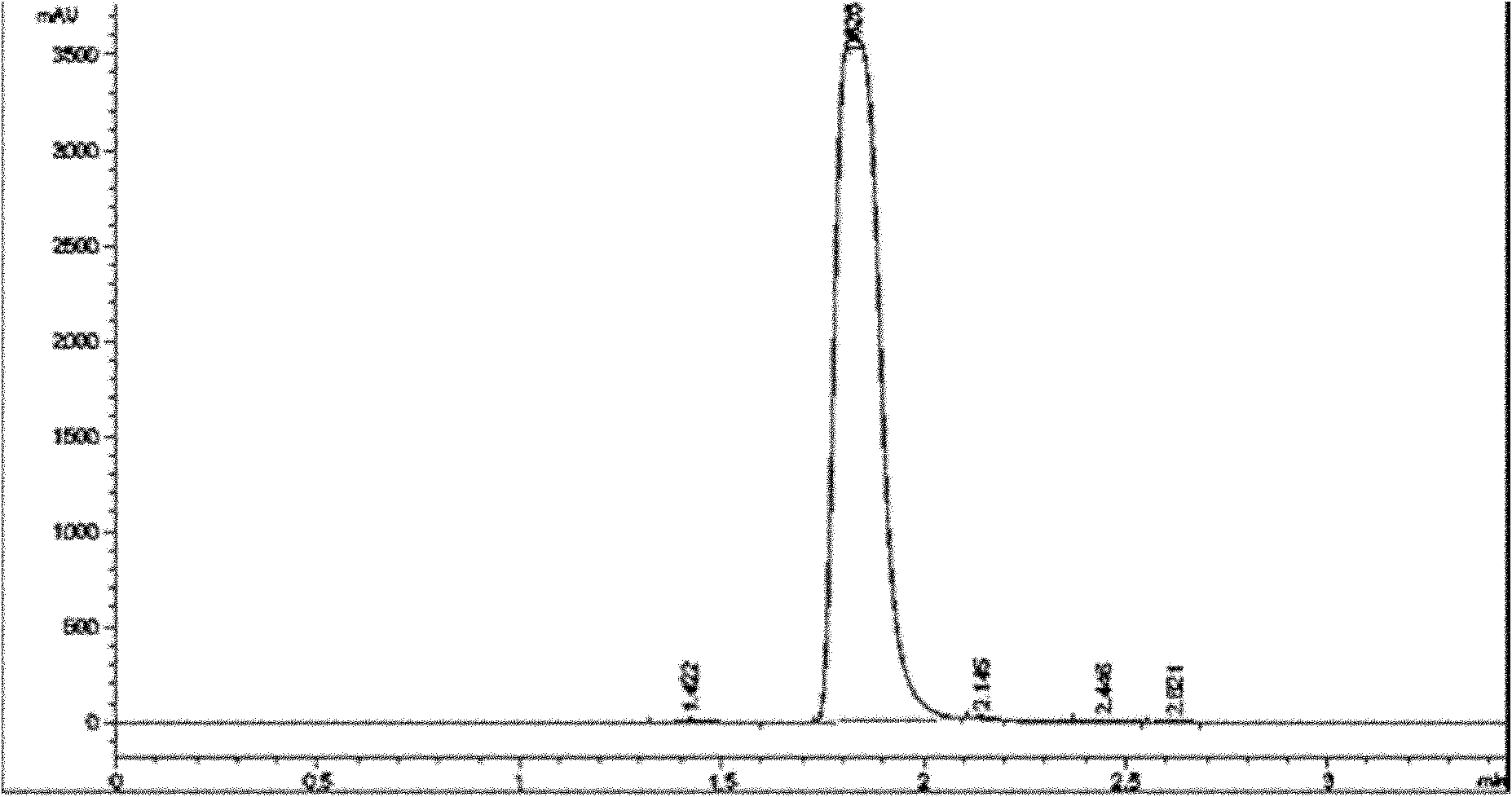

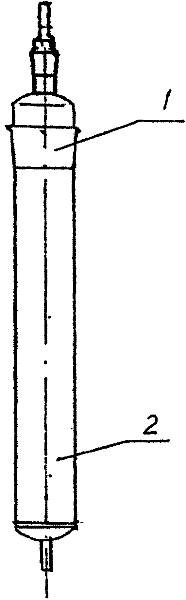

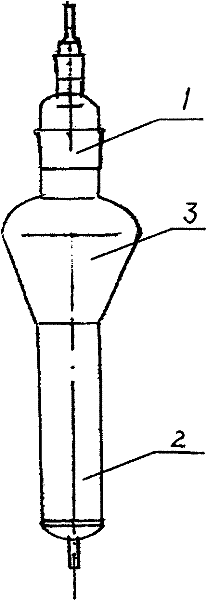

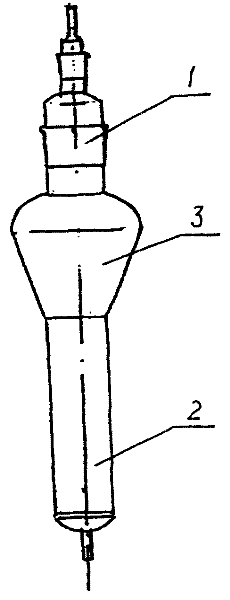

A method for separating and purifying lentinan

InactiveCN101161112AThe effect remains the sameAdapt to mass industrial productionFungi medical ingredientsFood preparationElutionPre treatment

The present invention relates to a method for separating and purifying lentinan, which is characterized in that after transforming the column type of the traditional chromatographic column to heterotype column, the lentinan coarse product is pretreated so as to ensure it to adopt the absorption of the heterotype column, the separating and purifying of the lentinan is changed to that of the lentinan dynamicly and high efficiently, thus to obtain single lentinan after a series of treatment of washing, elution, dialysis, deposition and freeze out etc. The advantage of the present invention is that it is suitable for producing large quantities and industrialisation, and can obtain high effect, low cost product with the precondition of method is simple as well as quality is good.

Owner:上海慈瑞医药科技股份有限公司

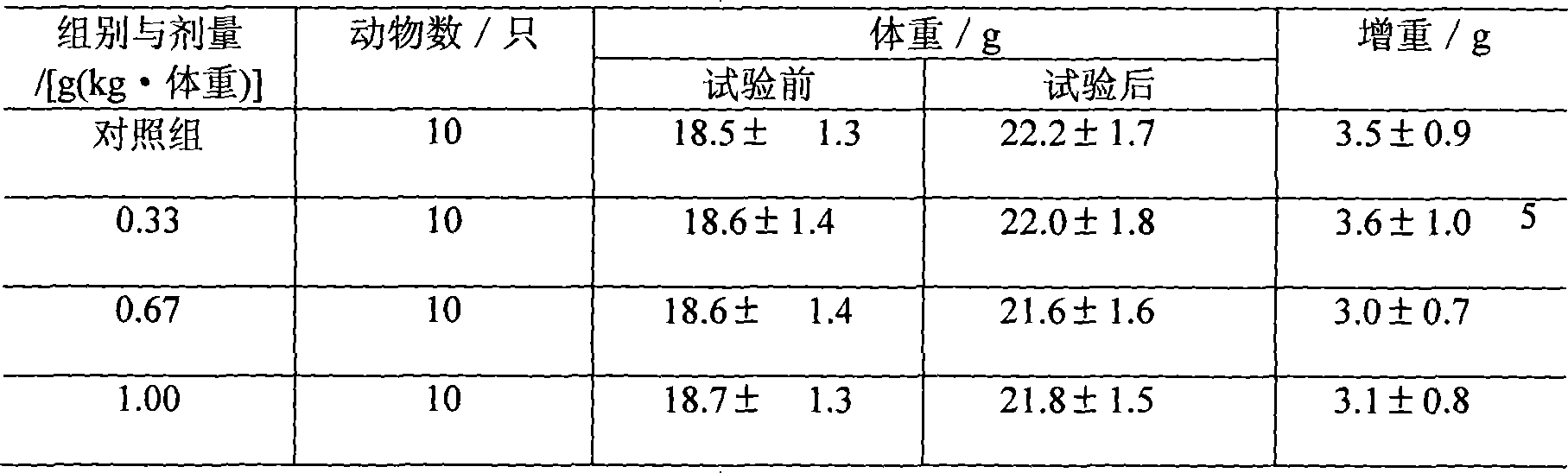

Cultivation method of acanthopanax root tree plant and acanthopanax root jujube tea with reinforced immunity function

InactiveCN101248731ARelieve physical fatigueReduce stressFertilising methodsTeaSide effectEleutherococcus senticosus

The invention relates to 'a cultivation method of an acanthopanax tea plant and the acanthopanax root tea with the purpose of enhancing immunity', which belongs to the field of health protection tea. The cultivation method of the acanthopanax tea plant is characterized in that: (1) soybean cakes are used for fertilizing the root; (2) pistil leaves of the acanthopanax are sprayed with foliar fertilizer every day a week before picking, wherein, the foliar fertilizer are prepared by jujube extract and ginseng distilled water. The acanthopanax root tea prepared by the tea plant has no other ingredients, which can obviously enhance the immunity of the organism of people with low immunity; meanwhile, the tea also has the advantages of convenient drinking, no small pieces and moderate sweet and sour taste. Clinical trials verifies that the acanthopanax root tea has not only the efficacy of enhancing immunity, but also the advantages of balancing blood pressure, relieving physical fatigue, delaying senility, reducing the incidence rate of headache, strengthening memory power and even increasing working strength for some people; in addition, the tea has no side effect and adverse reaction.

Owner:北京惠中铭捷生物科技有限公司

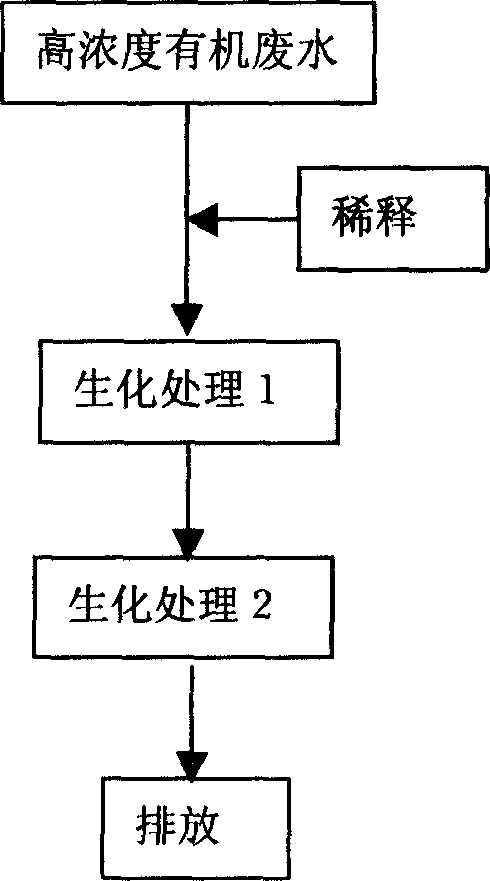

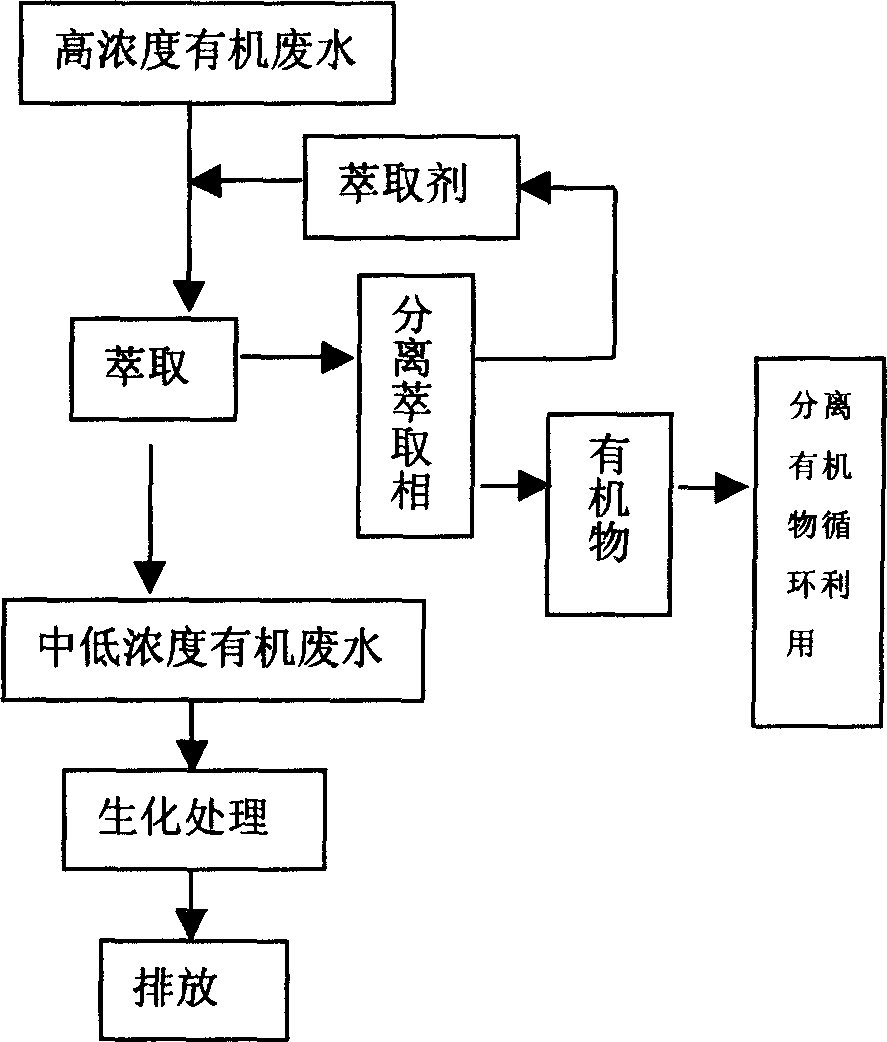

Method of treating phencyclic compound waste water using liquid-liquid extraction

InactiveCN1830821AEasy to operateMild conditionsWater/sewage treatment by extractionWater useBiodiesel

A process for treating the sewage of the compound containing the benzene ring by liquid-liquid extraction includes such steps as extracting by biologic diesel oil 1-5 times, vacuum distilling for respectively recovering said compound and biologic diesel oil, conventional biochemical treating, and draining.

Owner:ZHEJIANG UNIV OF TECH

Fireworks and firecrackers oxidant

InactiveCN1743297ASolve the problem of hygroscopicityLarge luminous radiusExplosivesFirecrackerNitrate

This new firework oxidant is a multi-element composite composed of two or more azotates and one or several perchlorates, among which perchlorates and organic encapsulation agent uniformly cover on the surface of the complex azotate, forming a layer of compact complex film. This invention resolves the puzzle of azotates' inclination to absorb moisture and insensitivity to explode. Therefore if as a substitute for potassium chlorate and potassium perchlorate simultaneously, it can resolve the security problem during production, cut down production cost and increase profit. Advantages: advanced technology and superior technical performance.

Owner:龙文革 +4

Preparation method of ultrathin woven fabric with anti-ultraviolet-photocatalysis, antibacterial and water-proof functions

ActiveCN107675326AWaterproof Stability GuaranteeImprove functionalityWoven fabricsMonocomponent polyesters artificial filamentPolyesterFiber

The invention provides a preparation method of an ultrathin woven fabric with anti-ultraviolet-photocatalysis, antibacterial and water-proof functions. The preparation method comprises the steps of weaving, setting, finishing and dyeing and forming, wherein in the step of weaving, the fibrous raw materials comprise anti-ultraviolet and antibacterial polyester or polyamide. The product prepared byusing the method has excellent functional effects in the anti-ultraviolet, antibacterial and water-proof aspects, wherein in the anti-ultraviolet aspect, the ultraviolet protection factor (UPF) valuecan reach 100, the ultrathin woven fabric can reach the highest anti-ultraviolet standard UPF value 50+, and compared with products prepared by using other methods, the gain is about 100%; according to the antibacterial effect, the sterilizing rate under photocatalysis (sun light) reaches 99%, and meanwhile, it can be stably ensured that the water-proof grade of the fabric reaches four.

Owner:苏州白云纺织科技发展有限公司

Ramie terry socks

The invention relates to a ramie terry-loop hosiery. Ramie is used as a raw material to prepare the ramie terry-loop hosiery by the following steps that: (1) a bio-enzyme of original ramie material is degumed to produce refined dry ramie; (2) the refined dry ramie and cotton are blended into ramie-cotton blended hank yarn; the hank yarn is subjected to reladling twice to reduce the twist number and the strength so as to prepare blank yarn; (3) the blank yarn is dyed and finished after the dyeing; (4) a silicon class softener is used to intenerate the finished yarn twice; and (5) the yarn is machined on a loom to be manufactured into the terry-loop hosiery. The terry-loop hosiery uses purely natural fibre as the raw material and has the efficacies of promoting blood circulation, removing blood stasis, eliminating toxicant and resisting bacteria without needing any drug additive; the ramie terry-loop hosiery has good performances of ventilation and moisture exhaust and can prevent foot sweat and foot odor, inhibit the growth of bacteria and prevent dermatophytosis and other foot diseases; and the ramie terry-loop hosiery is comfortable, soft and unchanged in effect after the terry-loop hosiery is washed repeatedly and is in particular suitable for high-aerobic activities.

Owner:左万万

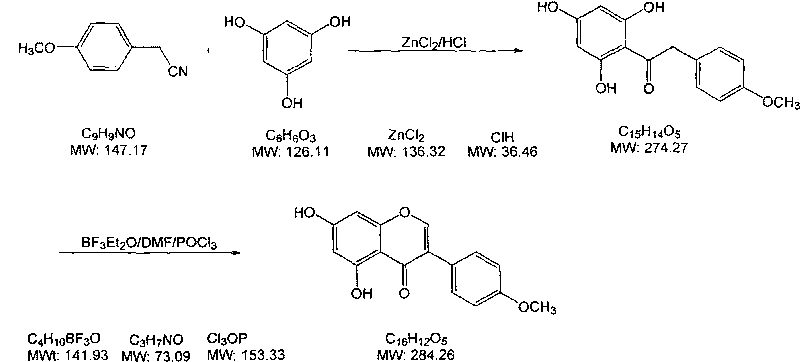

Method for synthesizing biochanin A

InactiveCN101717387AImprove solubilityDoes not affect the reaction effectOrganic chemistryPhysical/chemical process catalystsSolubilityDiethyl ether

The invention relates to a method for synthesizing biochanin A, which comprises the steps of: carrying out condensation and cyclization reactions on raw materials of methoxy phenyl-acetonitril and phloroglucin, and purifying to obtain the product biochanin A. The method is characterized in that in the first condensation reaction step, isopropyl ether or n-butyl ether is used as solvent for replacing ether of the prior art, and because the boiling point of the isopropyl ether or n-butyl ether is far higher than that of the ether and does not influence the reaction effect, industrialized mass production becomes possible. In addition, anhydrous zinc chloride and chlorine hydride gas are added as catalysts in the condensation reaction, and since the anhydrous zinc chloride can greatly increase the solubility of the chlorine hydride gas, the yield of products can be enhanced by more than one time. Furthermore, crude products are purified by mixed solvent N,N- dimethylformamide-methanol, and since the dosage of the solvent is just 5-10 times of the raw materials, the production cost is greatly reduced without changing the reaction effect. The method also has the advantages of simple operation, convenient operation and the like.

Owner:天津市佰斯康科技有限公司

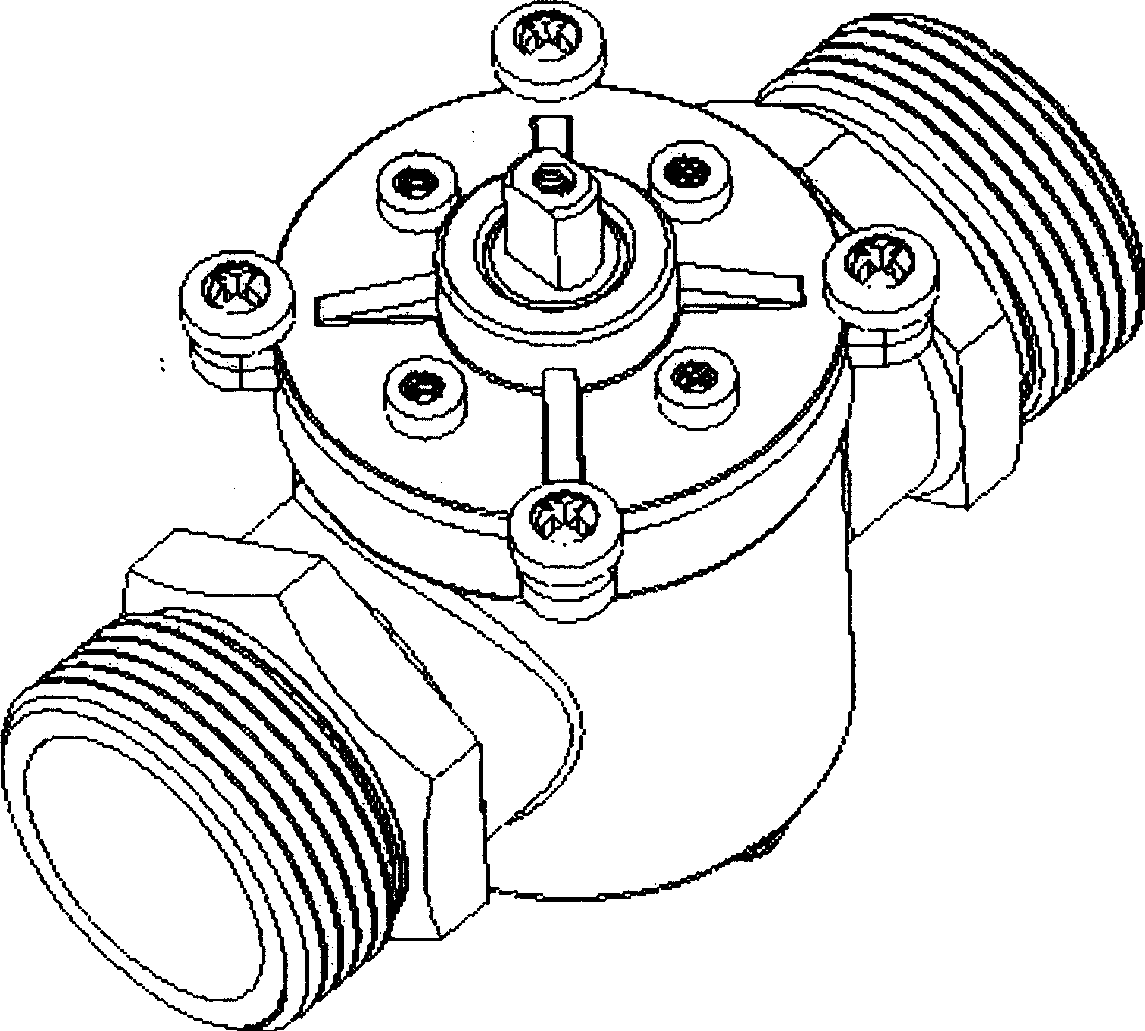

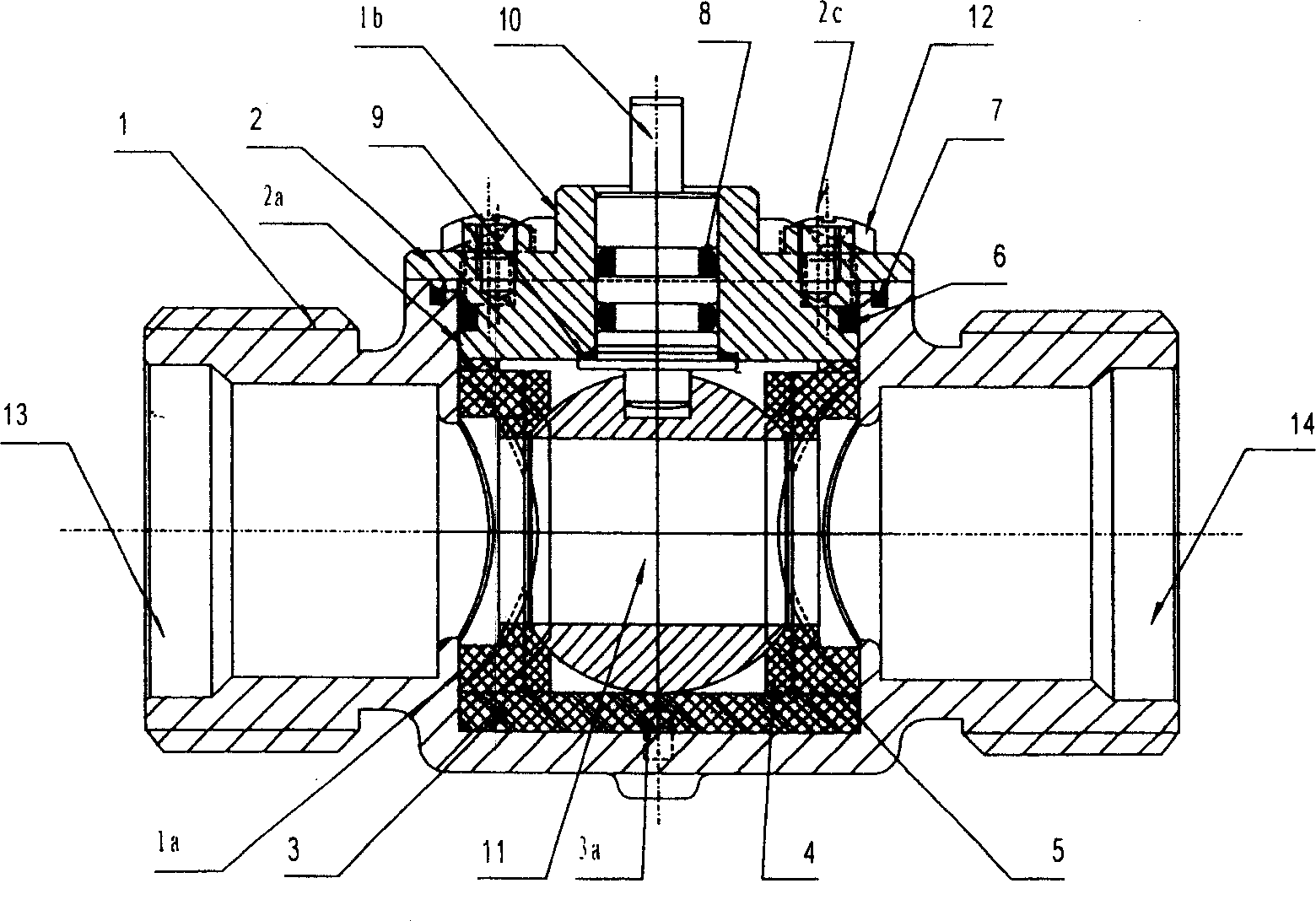

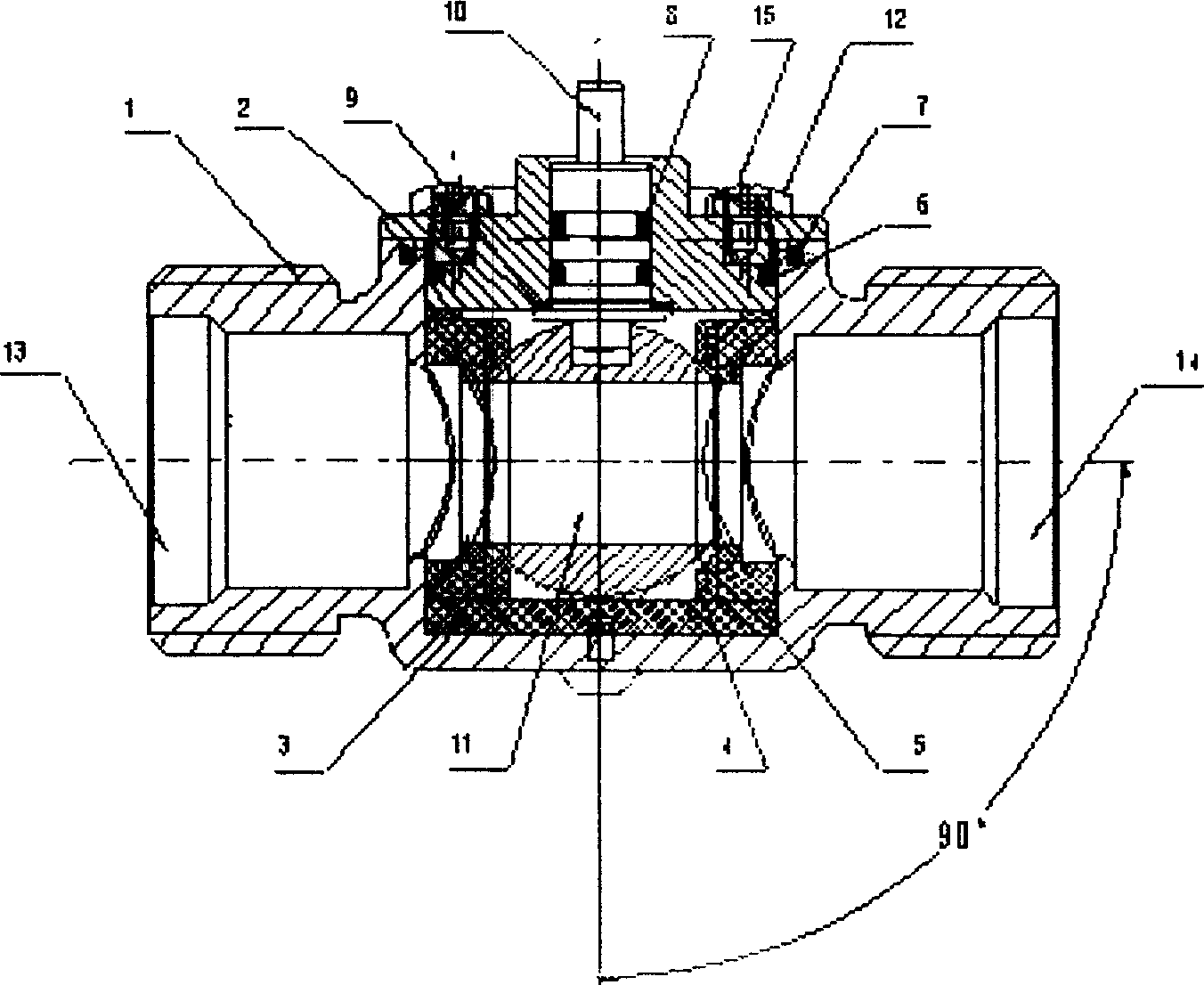

Upper assembled electric ball valve

The invention relates to an upper install ball valve, whose element is vertical to the water direction or the axle of water tube, wherein the invention has high control accuracy, stable property, and low rotation torque, while its idle rotation torque is not higher than 0.5N-m (0.05kgf-m); and the invention has high property than common ball valve, whose pressure resistance is improved from 1.6MPa to 3.5MPa. The inventive ball valve element is mounted on the valve body.

Owner:陈蕾

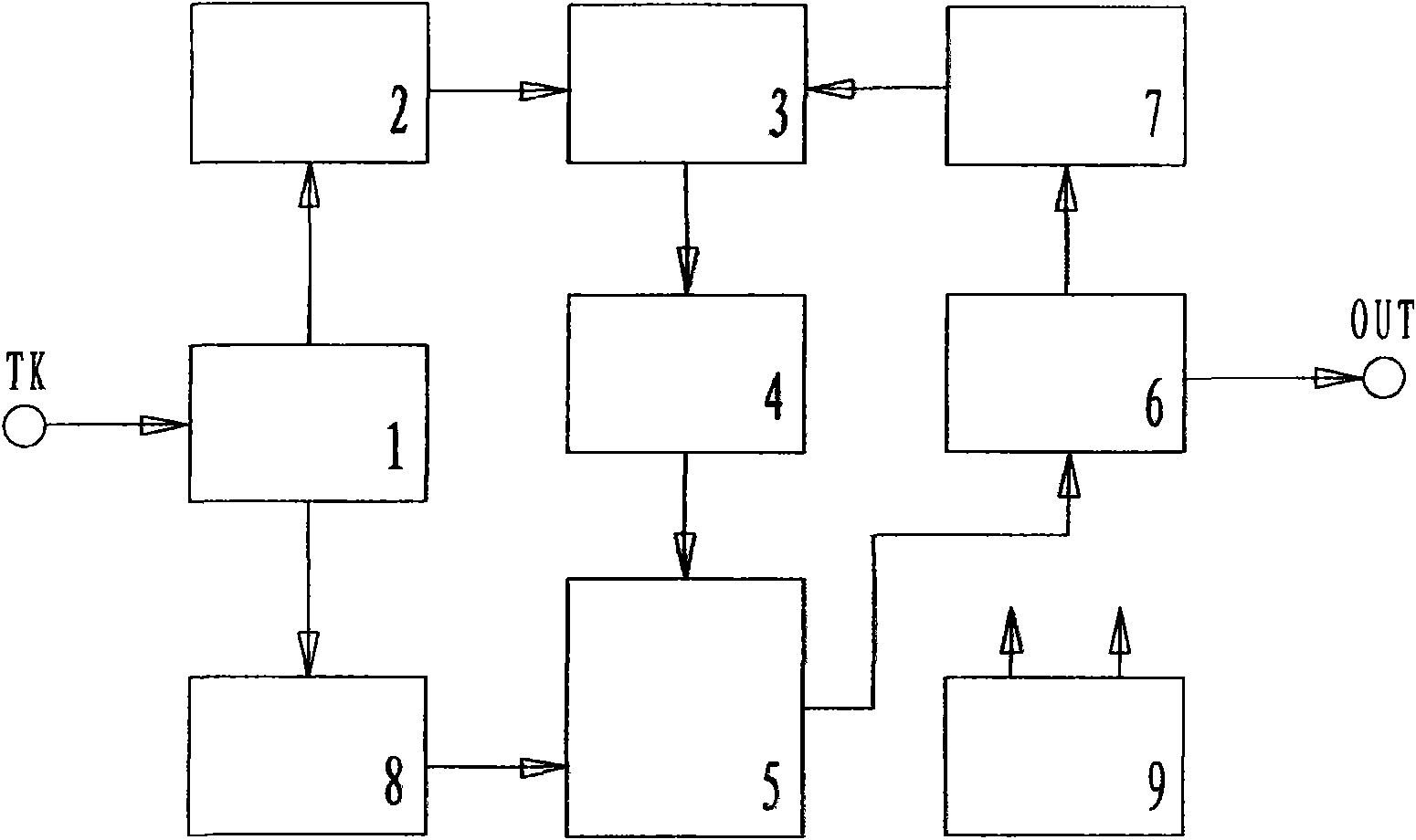

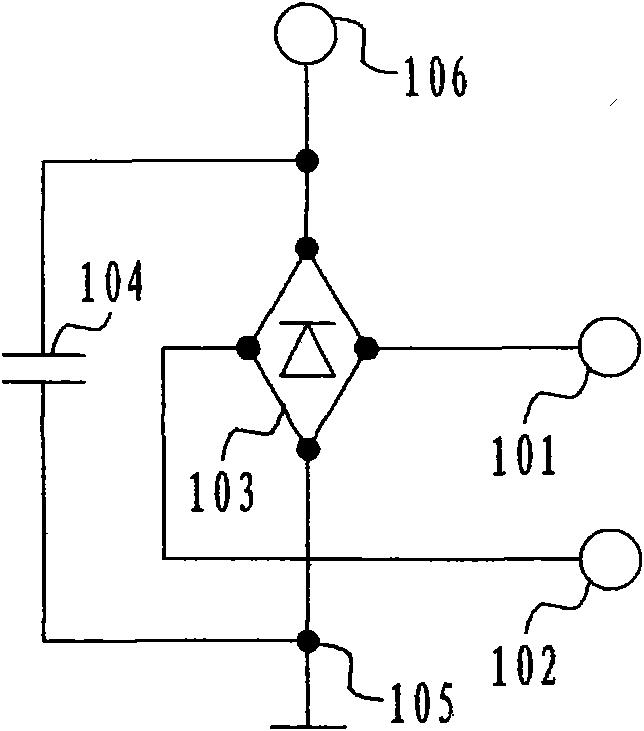

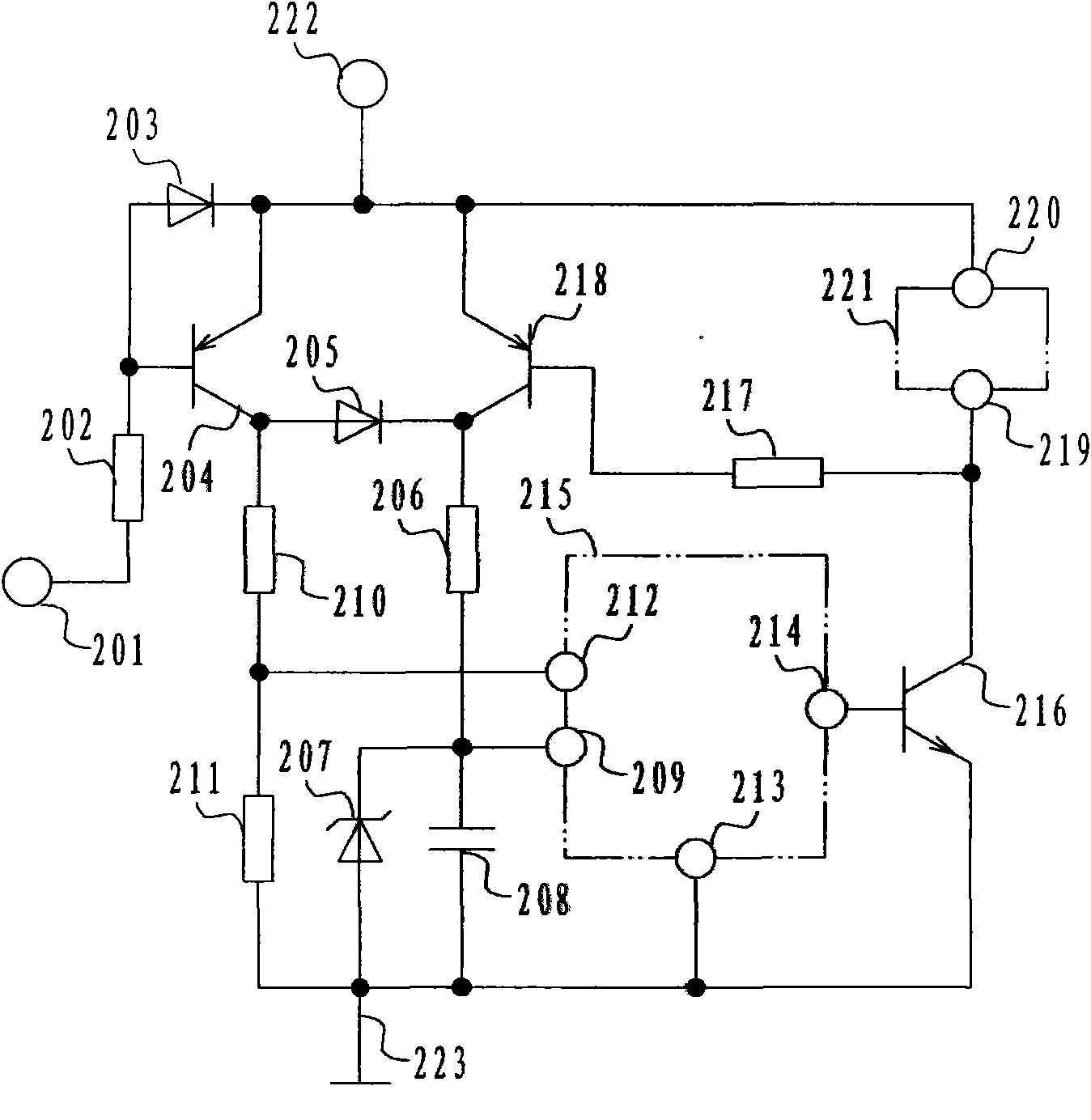

Scheme for touch switch consuming no power in off state

ActiveCN101771406AReduce power consumptionExtend your lifeElectronic switchingPositive feedbackAC power

The invention relates to a scheme for a touch switch consuming no power in the off state, which belongs to the field of the electronic switch, in particular to the category of touch type electronic switches. The commonly used touch type electronic switch consumes power in the off state, thereby causing a large amount of waste of energy. The invention provides a scheme for a touch type electronic switch consuming no power in the off state, and touch switches consuming no power in the off state with different functions can be manufactured with the scheme. In the scheme, an AC power supply supplies working power after rectification and filtration, the control electrode of a P type semiconductor device is connected with the output electrode of an N type semiconductor device, and the control electrode of the N type semiconductor device is connected with the output electrode of the P type semiconductor device, so as to form a positive feedback complementary switch circuit. In the feedback loop, a functional circuit is inserted, the feedback power is used as the power of the functional circuit, and the output signal of the functional circuit is adopted to control the on / off state of the feedback, thereby forming a complementary switch circuit with various functions. Then a touch circuit is connected in the feedback loop of the complementary switch circuit to provide a starting signal, so as to excite the turning of the complementary switch circuit with various functions.

Owner:刘忠宪 +3

Composite inorganic water purifying agent and preparation method thereof

InactiveCN102531117AAdapt to a wide range of waterImprove precipitation effectWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateRare earth

The invention discloses a composite inorganic water purifying agent and a preparation method thereof. The composite inorganic water purifying agent comprises water, hydrochloric acid, polyaluminium chloride, rare earth and activated water. The preparation method comprises the following steps of: (1), injecting the water into a reaction kettle and starting an acid mist recovery system; (2) starting a stirrer, injecting the hydrochloric acid and mixing completely; (3) adding the polyaluminium chloride and the rare earth and stirring continuously; (4) turning off the acid mist recovery system; and (5) injecting the activated water and stirring continuously. The composite inorganic water purifying agent prepared by the method is low in cost and has a good water purification effect.

Owner:陕西蓝清环境科技有限公司

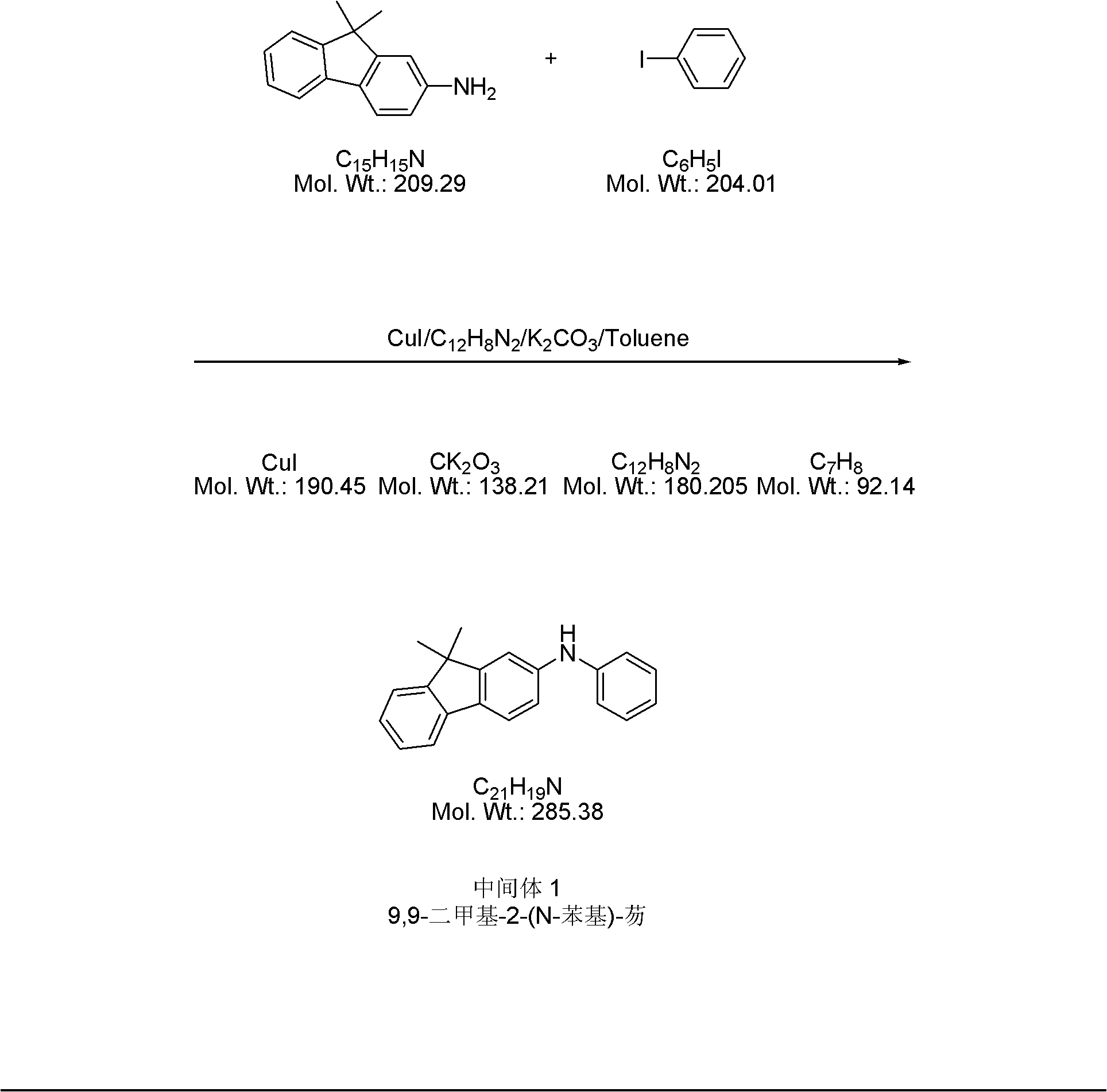

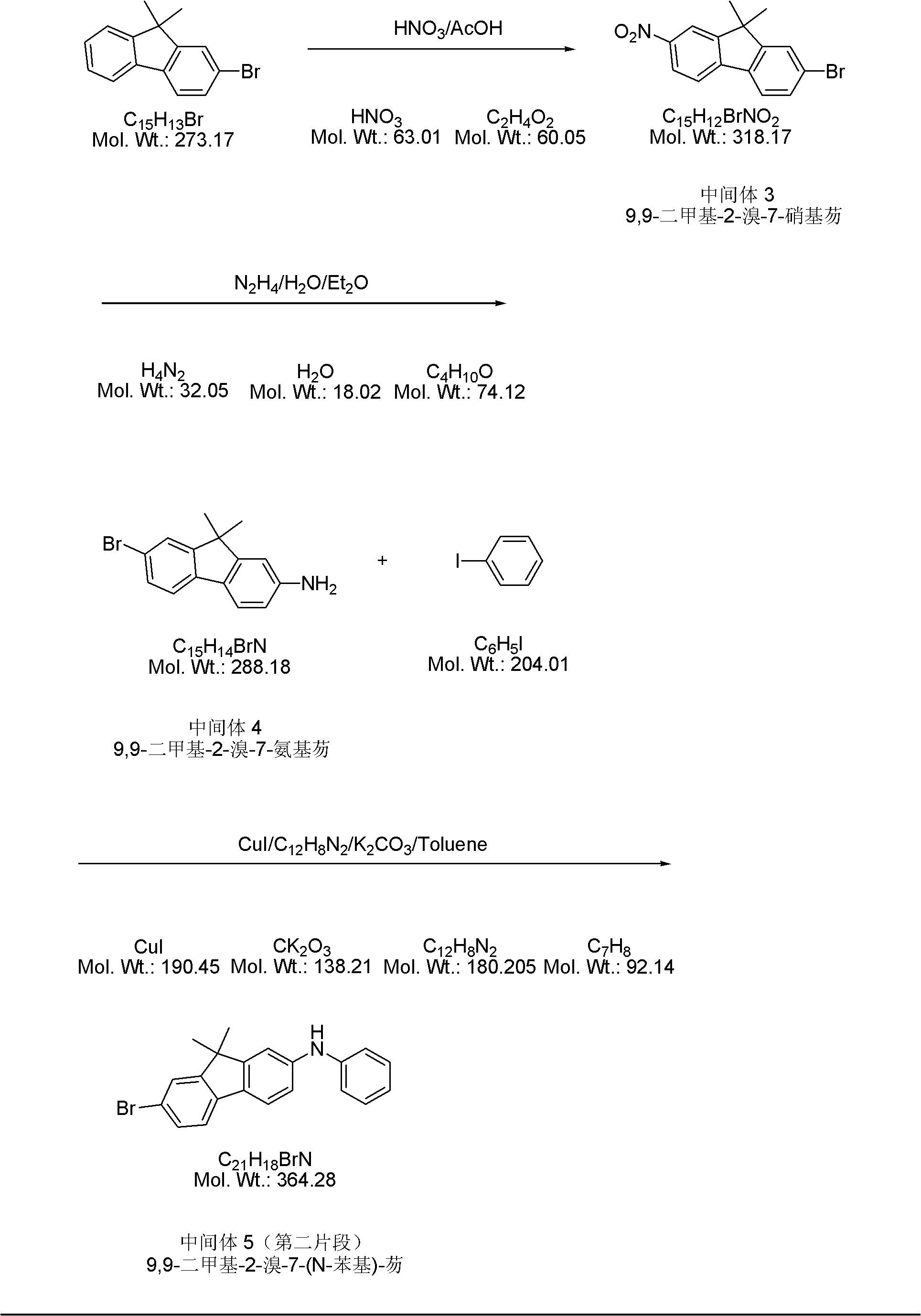

Method for synthesizing N,N'-diphenyl-N-(9,9-dimethyl-2-fluorenyl)-N'-(9',9'-dimethyl-7'-bromo-2'-fluorenyl)-benzidine

InactiveCN101973895ALow costImprove production safetyOrganic compound preparationAmino compound preparationSynthesis methodsBromine

The invention relates to a method for synthesizing N,N'-diphenyl-N-(9,9-dimethyl-2-fluorenyl)-N'-(9',9'-dimethyl-7'-bromine-2'-fluorenyl)-benzidine. In the method, a novel convergent synthesis route is adopted, and 9,9-dimethyl-2-aminofluorene and 9,9-dimethyl-2-bromofluorene are respectively used as starting raw materials for respectively preparing two fragments for synthesizing a final product;and finally, the two fragments are condensed and purified to obtain the final product N,N'-di-phenyl-N-(9,9-dimethyl-2-fluorenyl)-N'-(9',9'-dimethyl-7'-bromine-2'-fluorenyl)-benzidine. Because the price of the raw materials used by the synthesis method is low, the consumption of a solvent is small and the solvent is easy to recover, the production cost can be greatly reduced on the premise of guaranteeing the product purity and the productivity, thus the method is suitable for industrial production. In addition, the synthesis method has the advantages of simple operation, convenience, safety,and the like.

Owner:天津市佰斯康科技有限公司

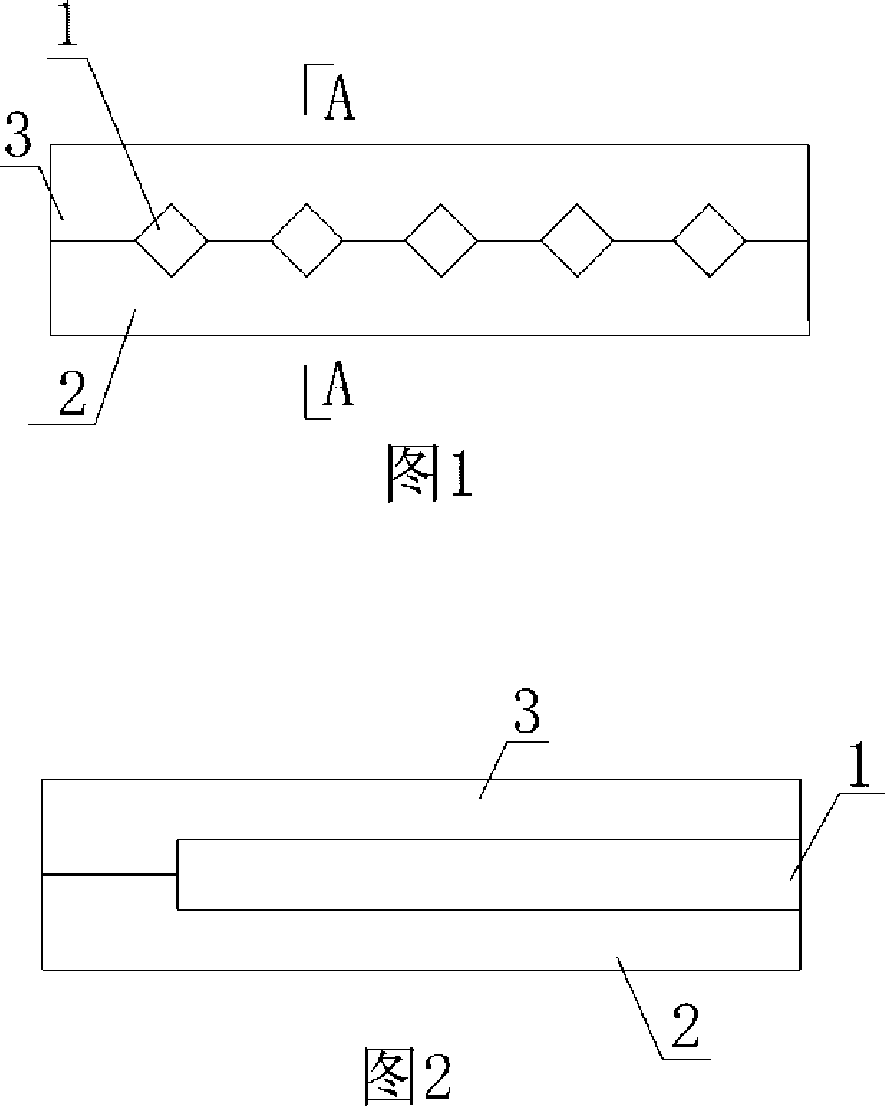

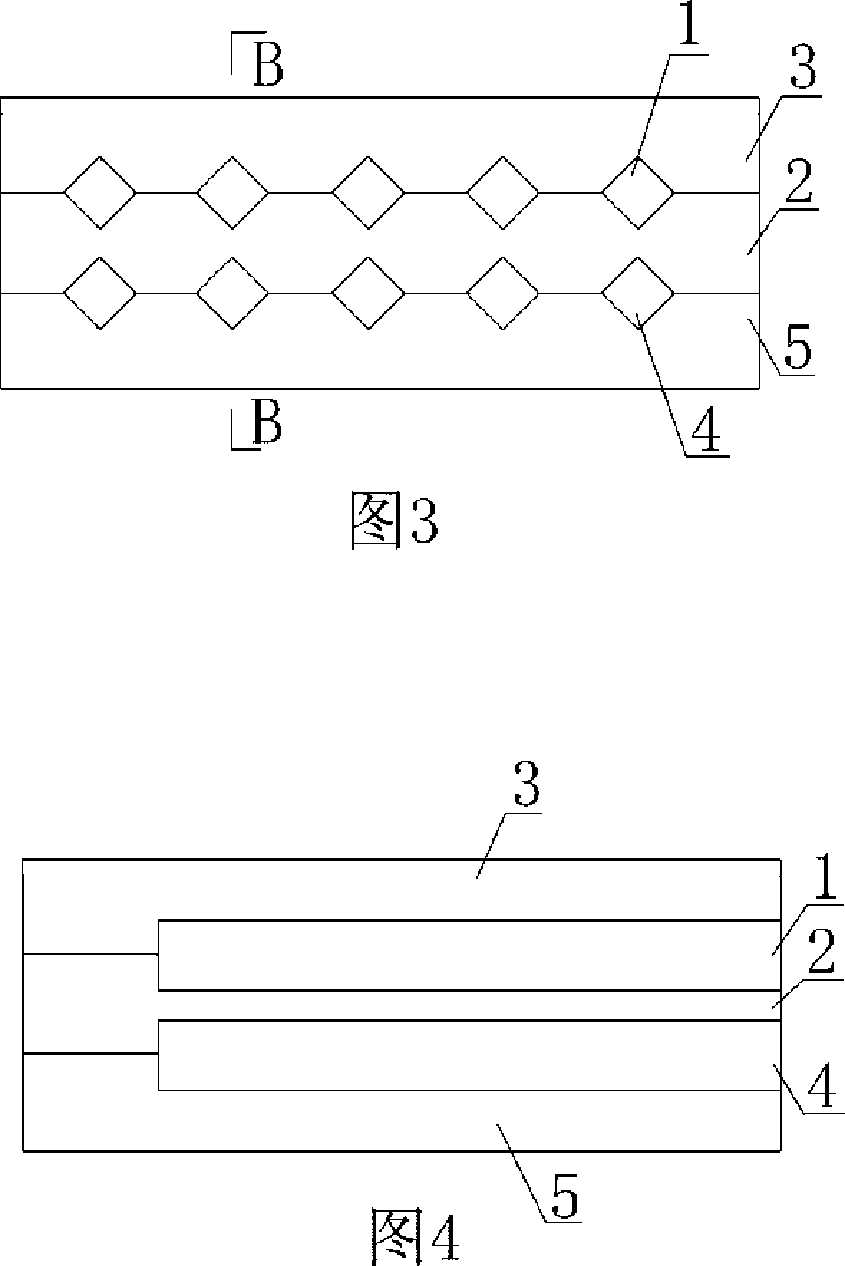

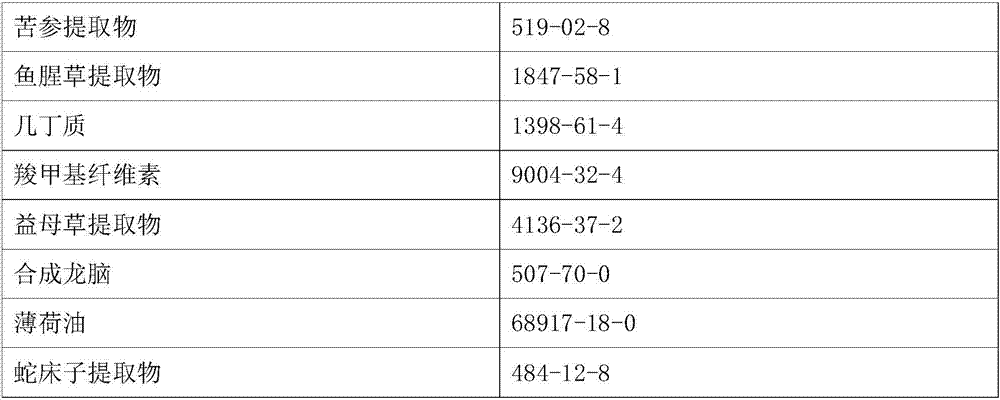

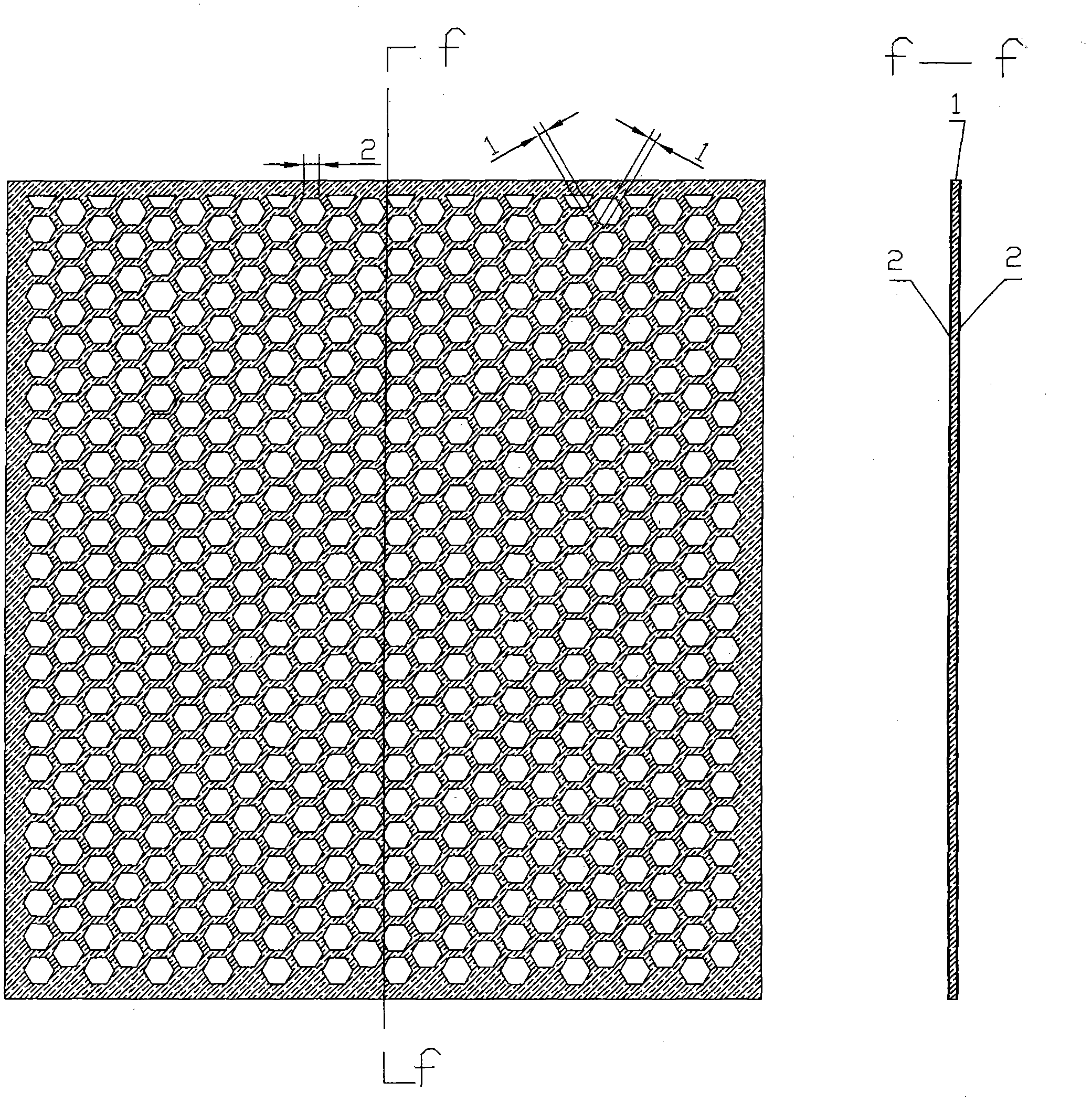

Grinder dresser with linerarly arranged diamond strips

InactiveCN101088707ALow costThe effect remains the sameGrinding devicesAbrasive surface conditioning devicesAlloyMetal powder

The grinder dresser with linearly arranged diamond strips consists of a cutter body and a mold sheet. The mold sheet has artificial diamond strips arranged in one single or several rows in the alloy sintering body, and all the artificial diamond strips with diamond-shaped cross section are embedded in V-grooves of the metal support, with the parts of the artificial diamond strips outside the V-grooves being sintered integrally with the metal powder. The present invention has artificial diamond strips with ends in the same straight line, low cost, high durability and high machining accuracy.

Owner:崔洲平

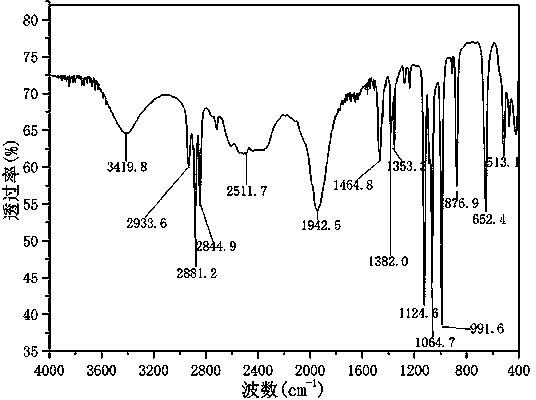

Heavy metal ion absorbent and preparation method thereof

ActiveCN106423112ARealize resource utilizationAvoid secondary pollutionOther chemical processesWater contaminantsWater basedSorbent

The invention discloses a heavy metal ion absorbent and a preparation method thereof. The heavy metal ion absorbent is mainly prepared from 70-95 parts of water-based black ink printing effluent extract and 5-30 parts of pumice stone and sepiolite in parts by mass. The preparation method comprises steps as follows: the water-based black ink printing effluent extract is blended into paste with a certain solid content, and appropriate alkaline substances are added until the paste is neutral; a certain quantity of pumice stone and sepiolite granules are added to sludge and stirred to be uniform, so that the specific gravity of the sludge is adjusted; the sludge is heated to 50-90 DEG C while being stirred and then hydrated until the sludge becomes blocky, the blocky sludge is subjected to hot pressing until the water content is lower than 50% and then dried, and water obtained during dehydration is drained; the sludge is heated to 350-750 DEG C in a vacuum state and kept at the temperature for 1-5 h; the sludge is broken into granules after being cooled to be at a certain temperature, sprayed with a wetting agent solution in the mass concentration being 0.05%-0.2% and mixed uniformly. The prepared heavy metal ion absorbent can be recycled after regeneration.

Owner:QINGDAO UNIV

Multifunctional biological preparation

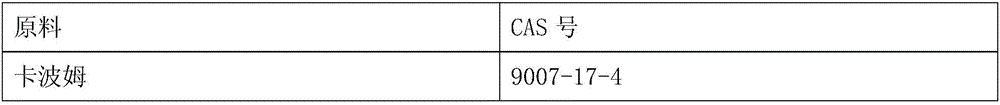

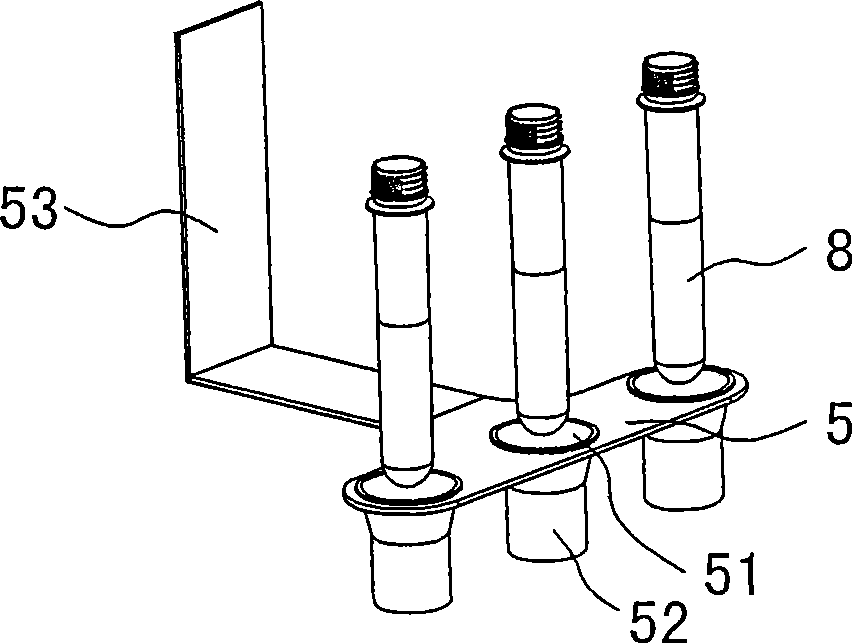

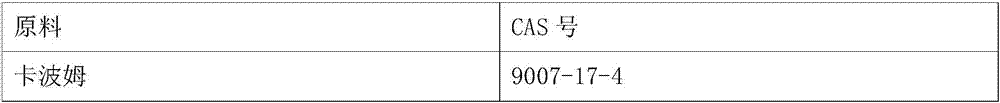

ActiveCN106552078AImprove immunityImprove mental stateHydroxy compound active ingredientsAntipyreticCelluloseChlorhexidine Acetate

The invention relates to the field of the medical technology, in particular to a multifunctional biological preparation. The multifunctional biological preparation comprises the following components comprising, by mass, 831-856 parts of water, 50 parts of glycerin, 50 parts of propylene glycol, 6 parts of carbomer, 0-6 parts of radix sophorae flavescentis extract, 5 parts of houttuynia cordata extract, 1-2 parts of chitin, 10 parts of cellulose, 5-20 parts of motherwort extract, 0-1 part of hyaluronic acid, 5 parts of borneol, 0-3.5 parts of ethyl alcohol, 1 part of chlorhexidine acetate, 0-0.5 part of peppermint oil and 0-20 parts of common cnidium fruits. The multifunctional biological preparation can significantly improve the immunity, especially the immunity of the genital system and significantly relieve the dysmenorrheal symptom. The multifunctional biological preparation can significantly improve the health state and the youthful state of the genital system and comprehensively solve various genital problems.

Owner:GUANGZHOU GREEN HUMAN BIOTECH

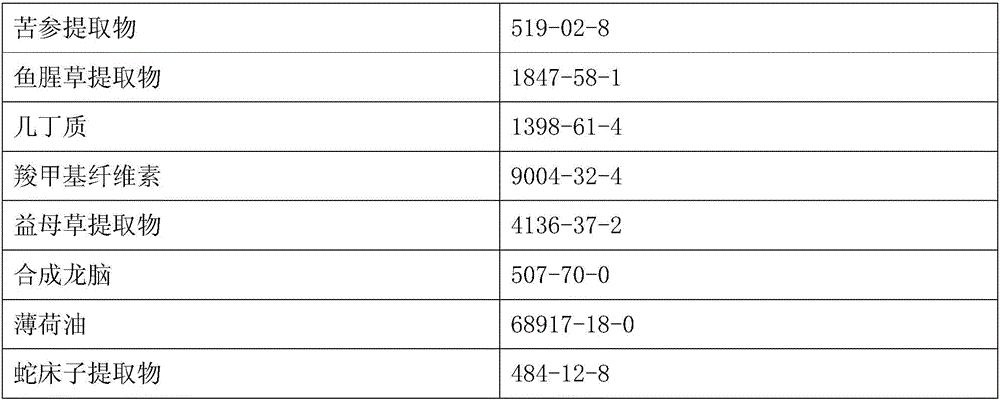

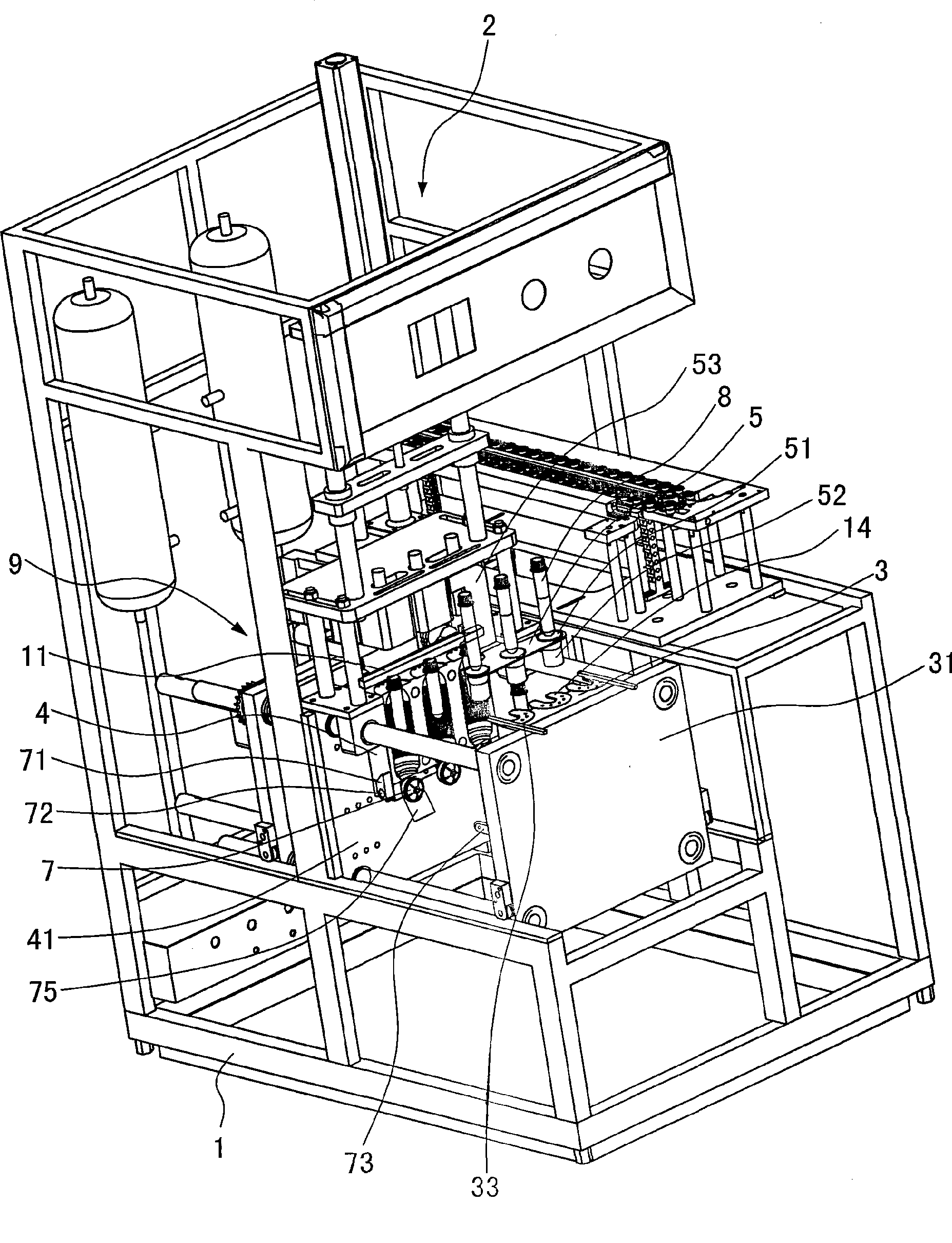

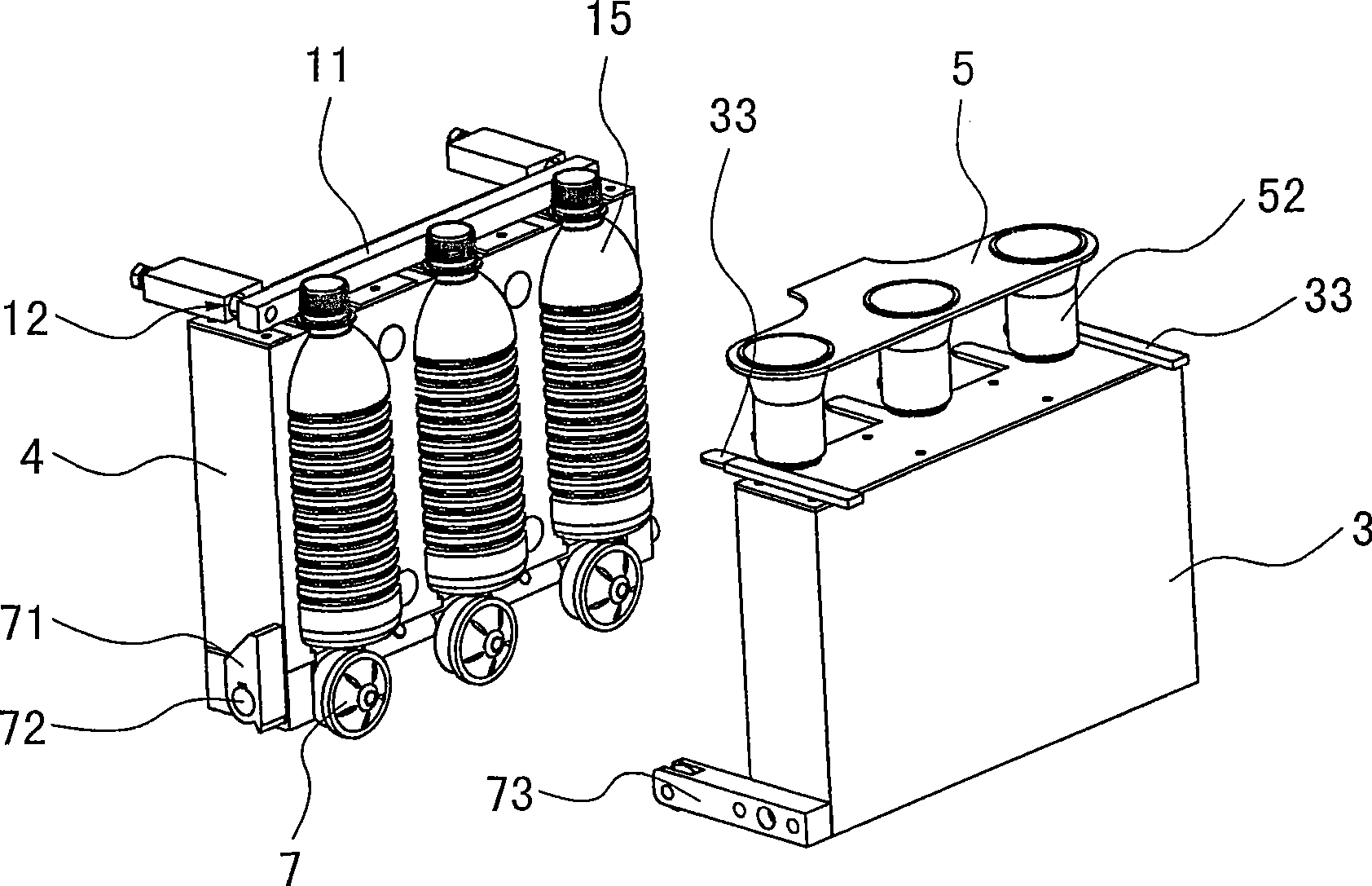

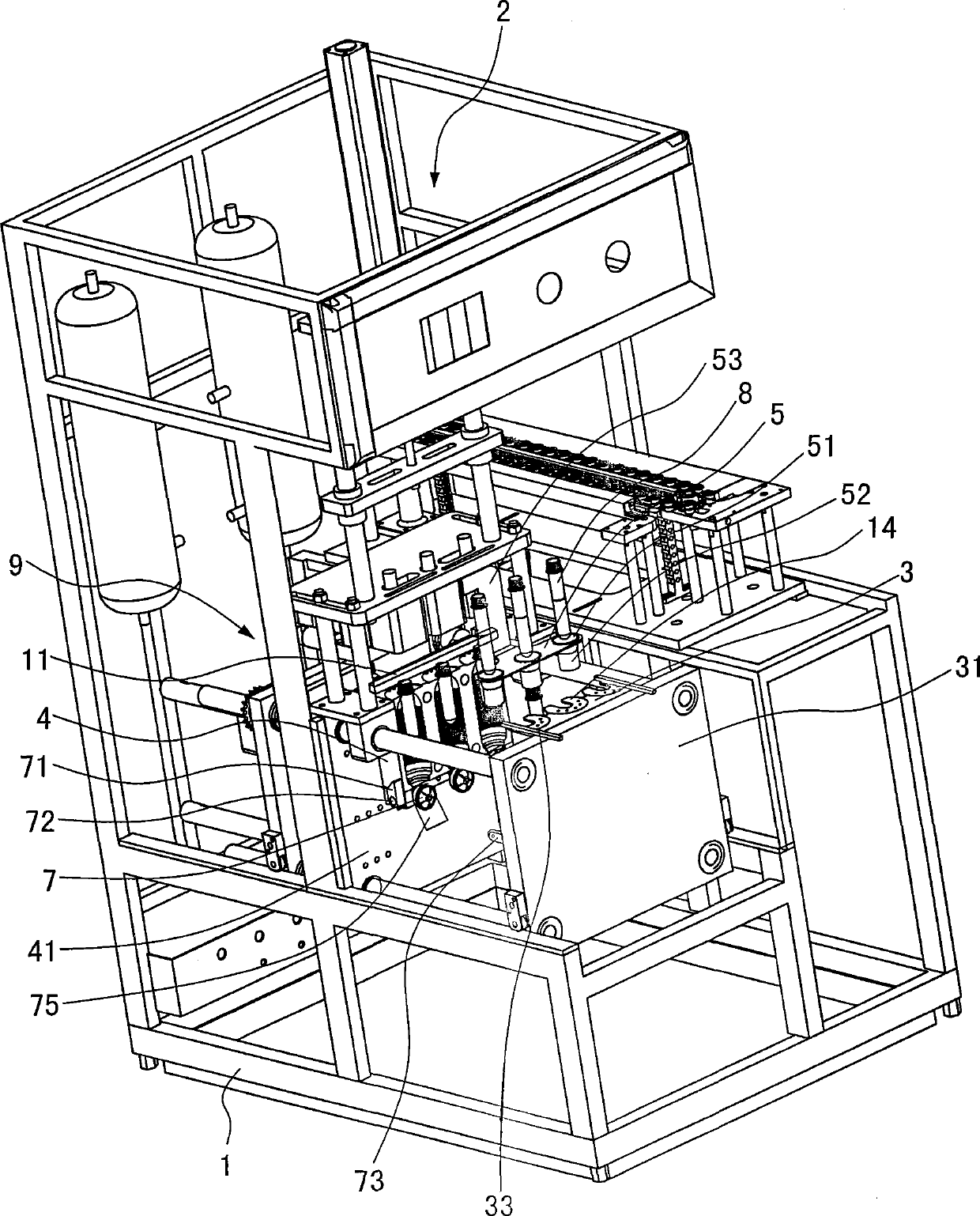

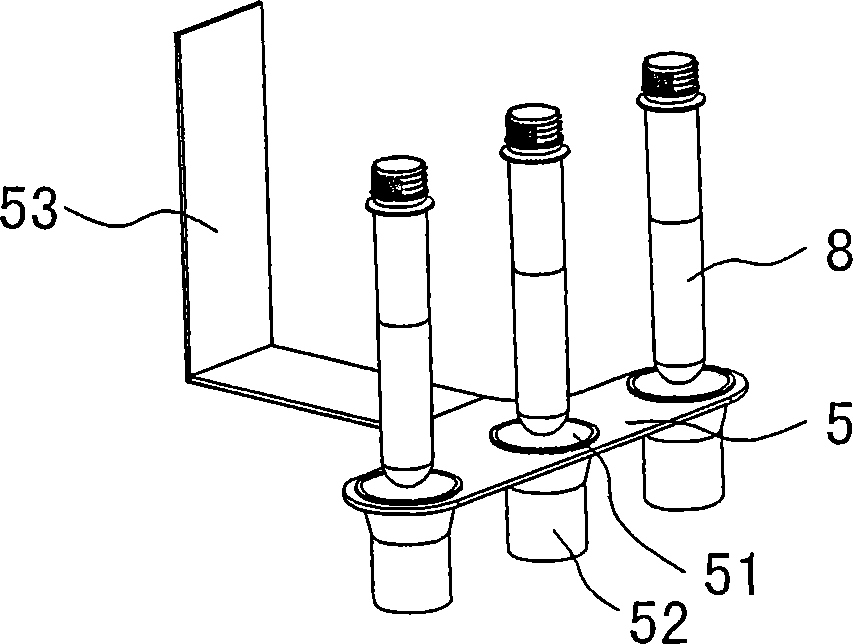

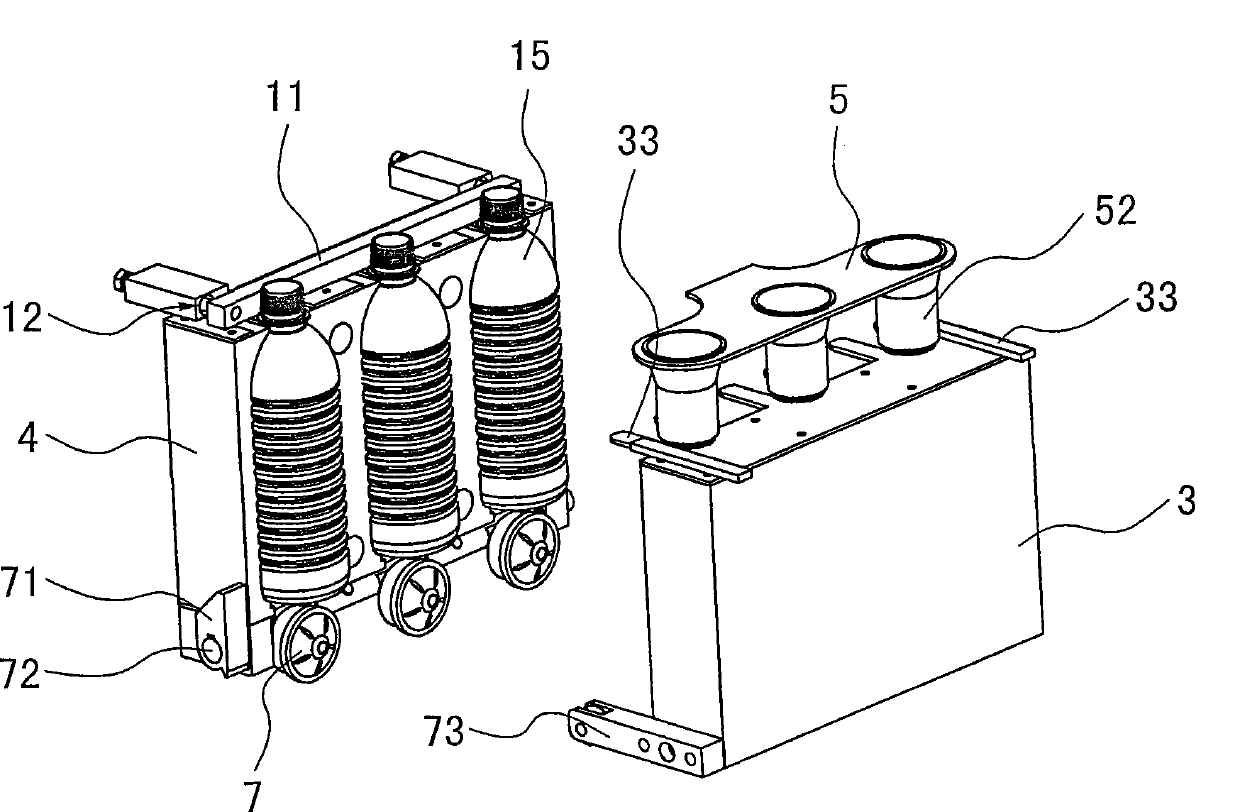

Blank supplying and automatic bottle shedding mechanism of plastic blowing machine

The invention relates to a blank supplying and automatic bottle shedding mechanism of a plastic blowing machine, which comprises a stander, a template, a die, a die opening and closing mechanism and a blowing mechanism, wherein the template, the die and the die opening and closing mechanism are arranged on the stander. The blank supplying and automatic bottle shedding mechanism of the plastic blowing machine is characterized in that a blank supplying device and an automatic bottle shedding mechanism are arranged on the die, the blank supplying device comprises a supporting plate which is arranged on the stander or the die, a plastic bottle blank guide cylinder is arranged in the supporting plate, the center of the guide cylinder is in the same straight line as the center of the die, and ablank receiving fork is arranged on a die orifice of the movable die and contacted with a plastic bottle blank; the automatic bottle shedding mechanism comprises a bottle mouth extruding device and abottom die rotating device, the bottle mouth extruding device comprises a pushing plate and a spring which are fixed on the die orifice of the fixing die, and a post rod is arranged on the movable die and matched with the pushing plate; and the bottom die rotating device comprises a rotating shaft which is connected in series with bottom dies, the head of the rotating shaft is provided with a pulling block which is contacted with a contact rod arranged on the stander or the die to rotate, and the rotating shaft is provided with a resetting spring.

Owner:蔡业

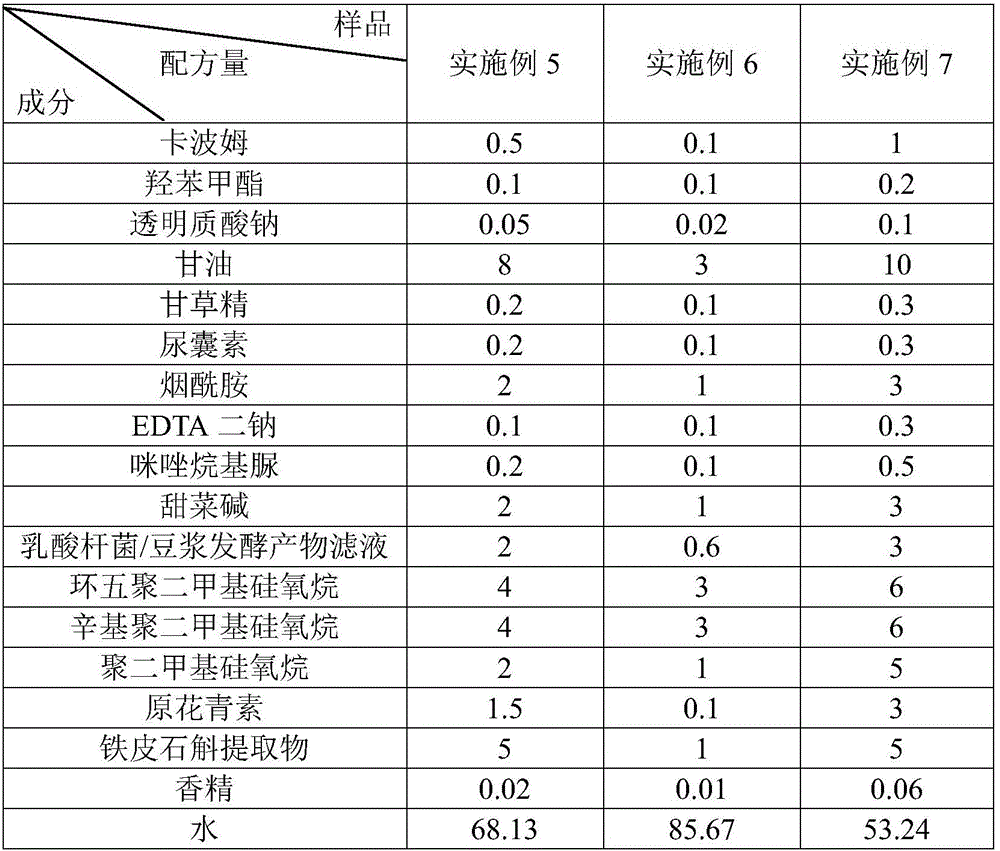

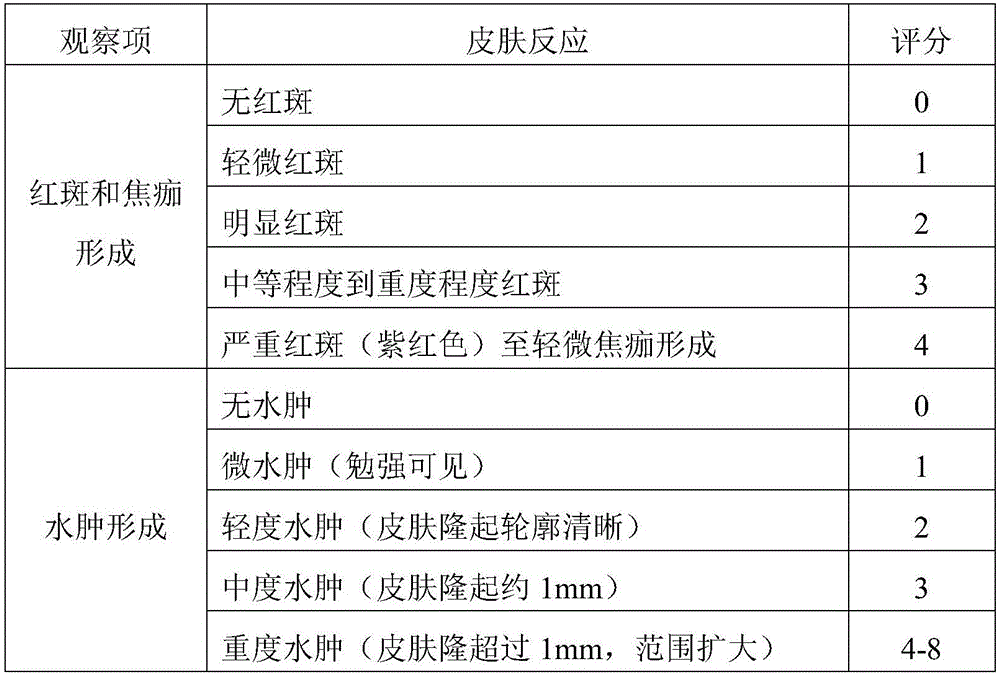

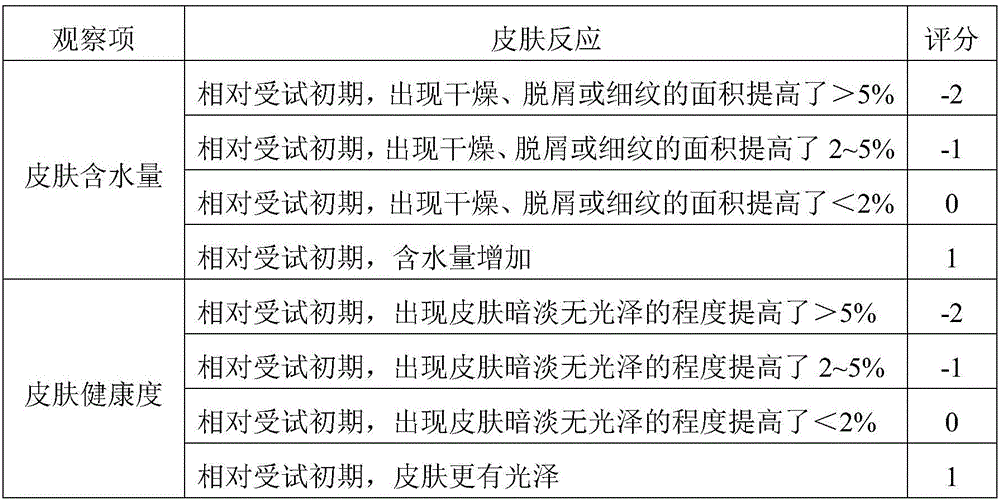

Moisturizing cream

InactiveCN106389305ADecentralized and easy to controlAdjust dispersionCosmetic preparationsToilet preparationsProanthocyanidinMedicine

The invention discloses a moisturizing cream. The moisturizing cream comprises, by mass, 1.0-3.0 parts of nicotinamide, 0.6-3 parts of lactobacillus / soybean milk fermentation product filtrate, 0.1-3 parts of proanthocyanidins and 1-5 parts of Dendrobium officinale extract. The moisturizing cream has a skin allergy possibility reducing effect.

Owner:上海娇云日化有限公司

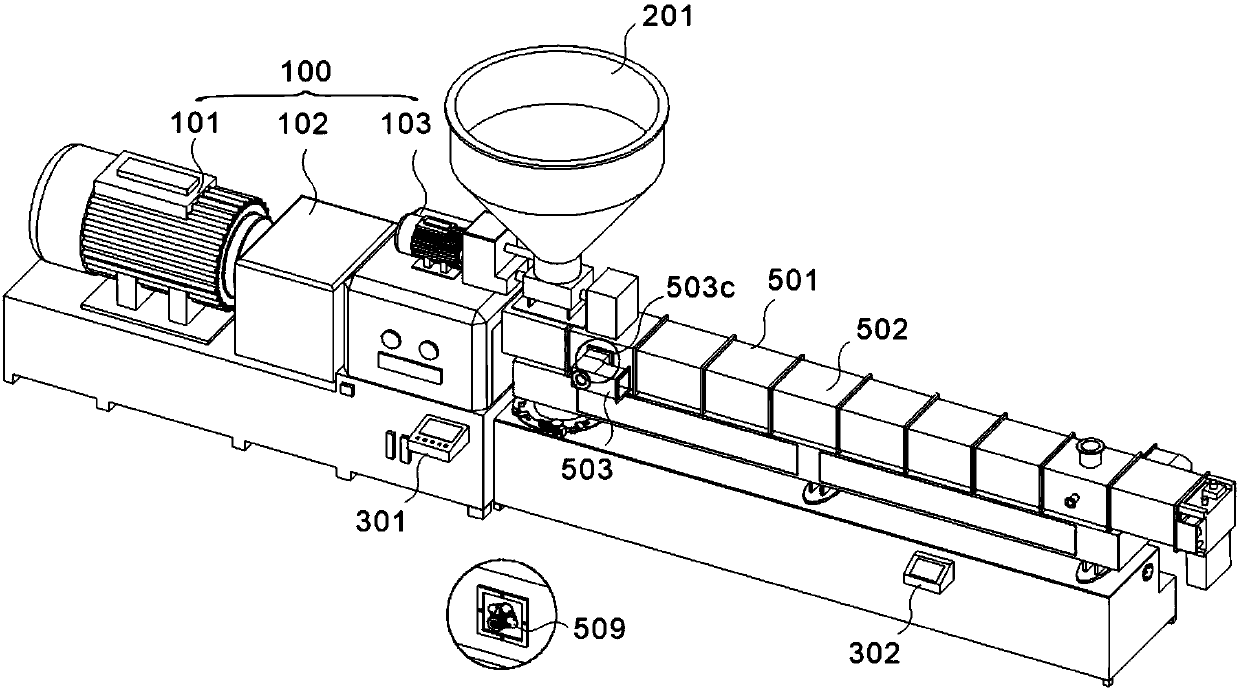

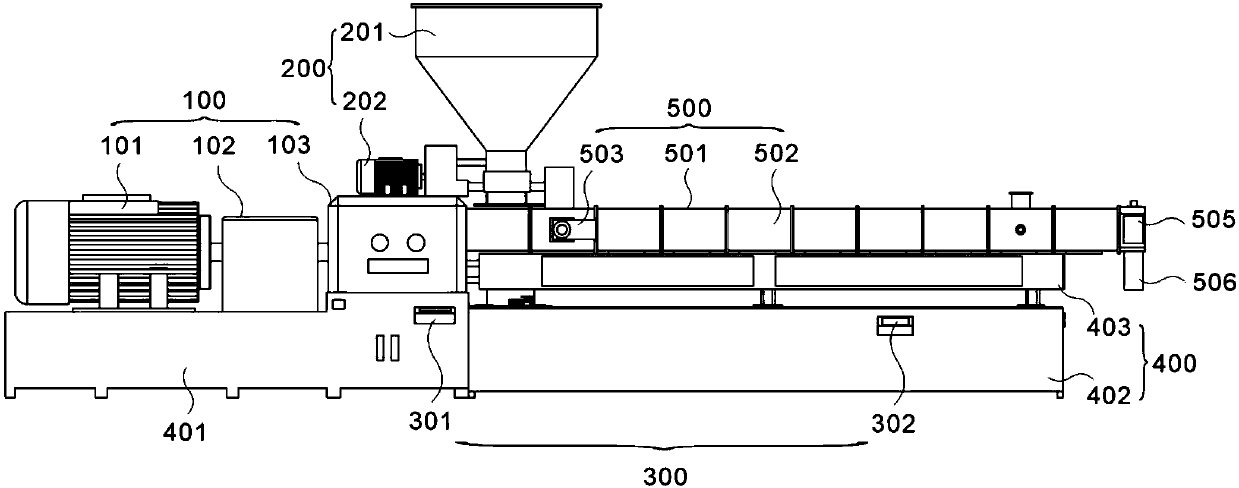

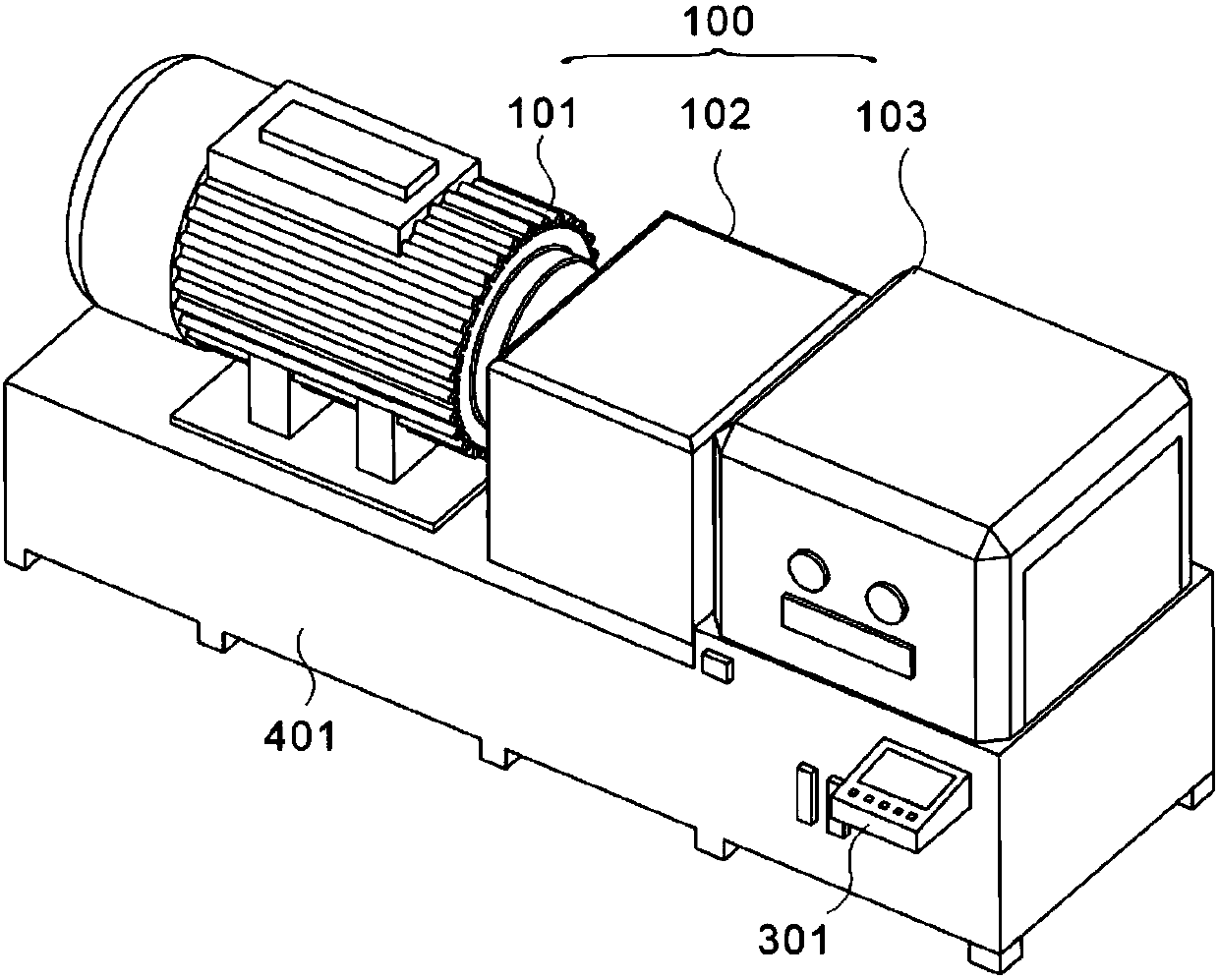

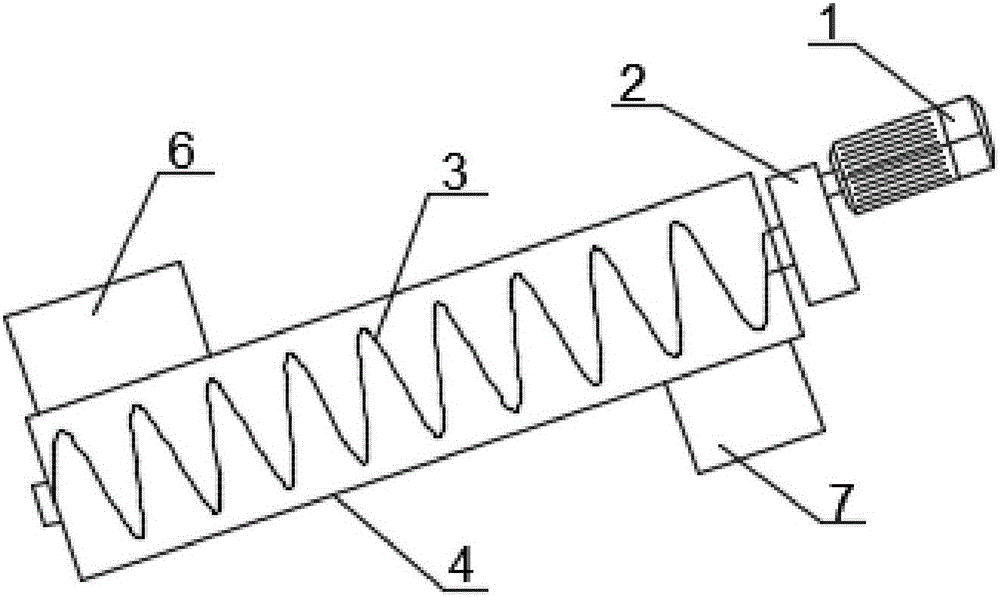

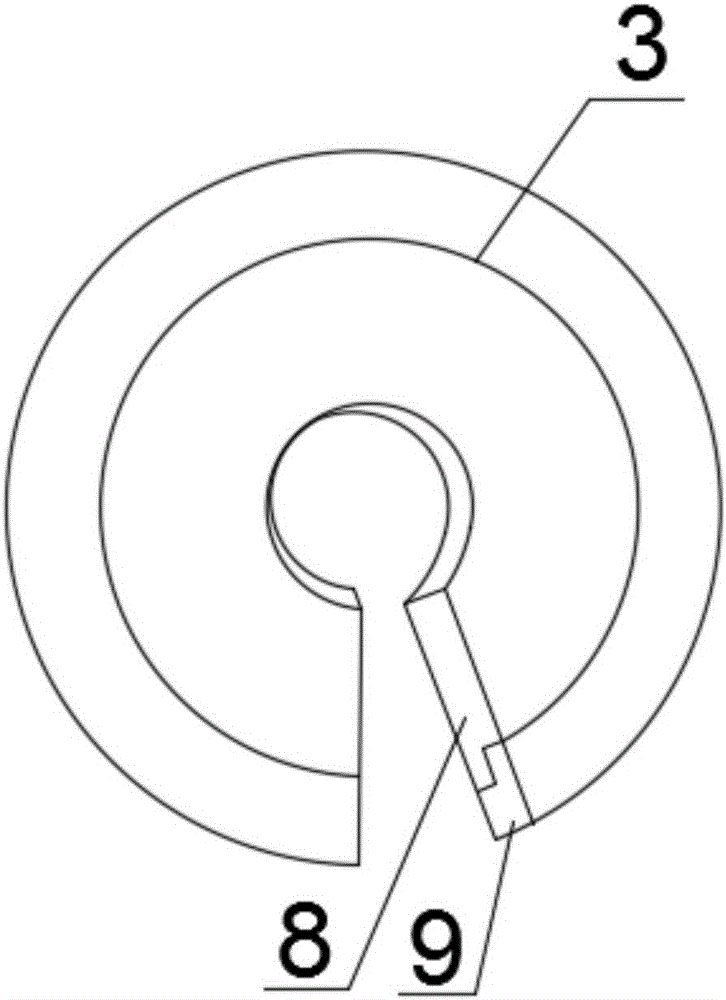

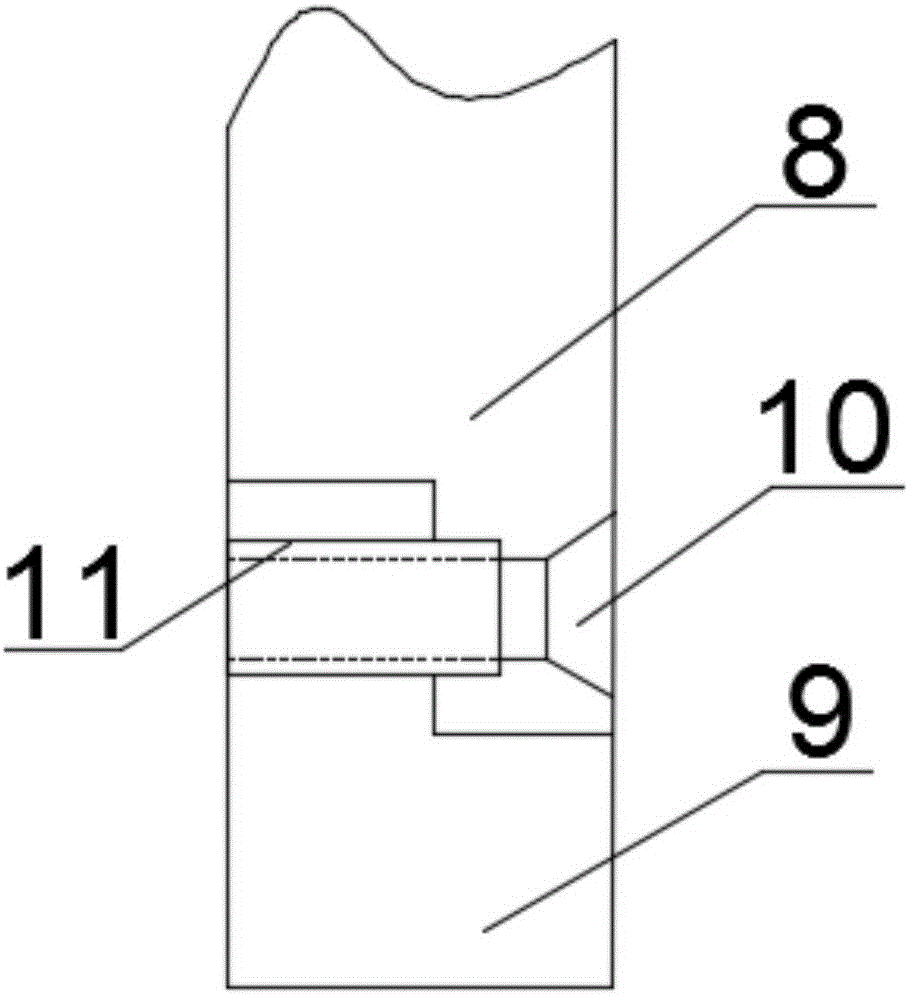

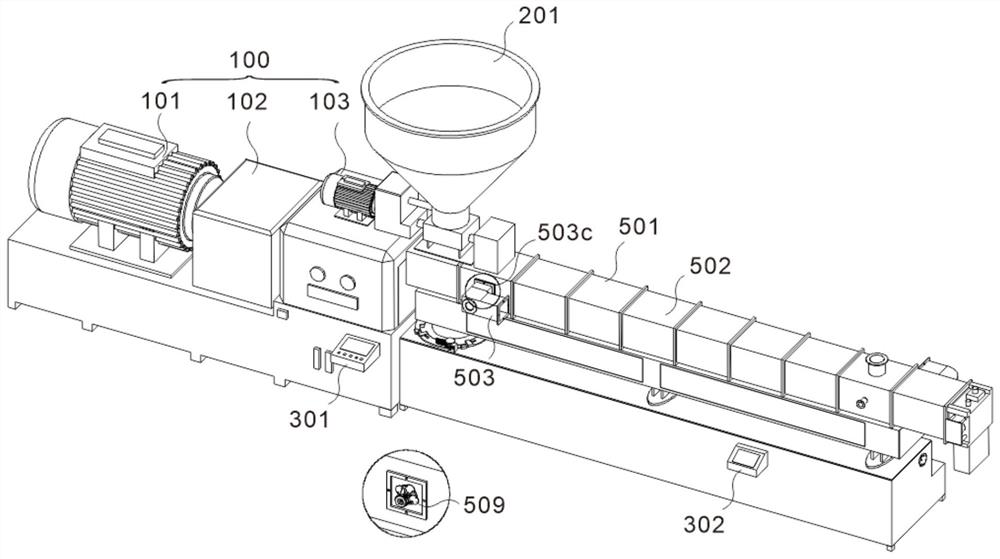

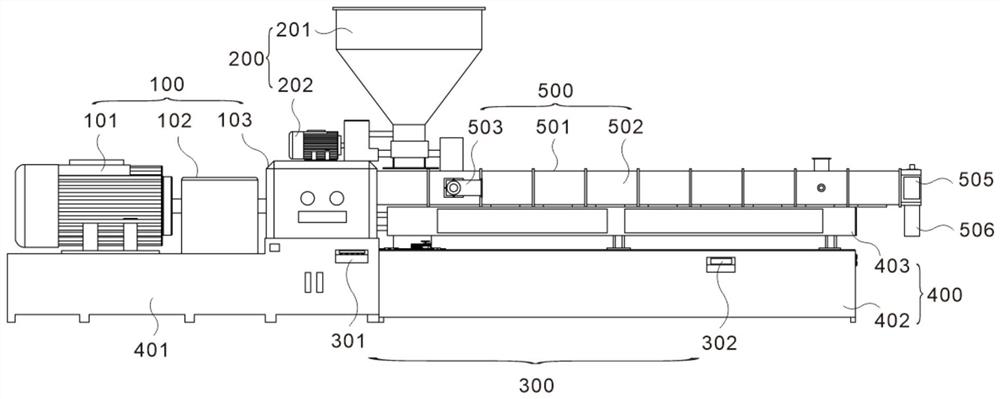

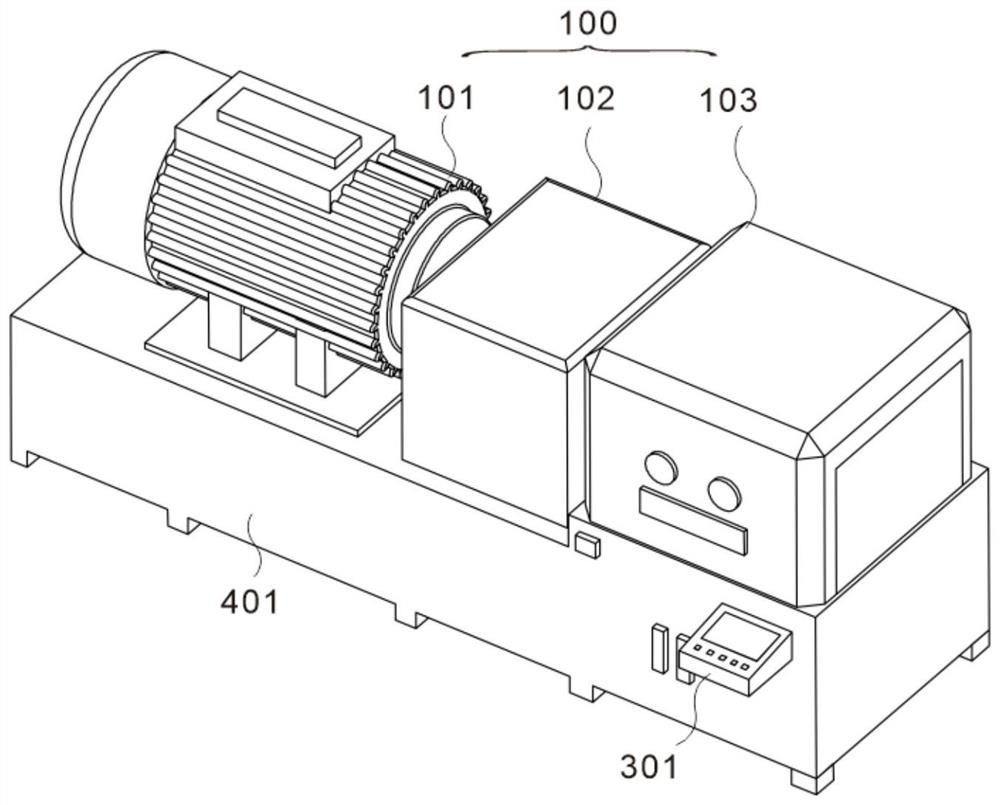

Shaftless screw conveyor

InactiveCN105775632AEasy to replaceMeet the requirements of all aspects of usePackagingEngineeringMaterial resources

A screw conveyor which is widely used nowadays consists of three parts of a speed reduction motor, a blade and a barrel body; a material is restricted in the barrel body; the screw blade which is driven by the speed reduction motor is an integral blade; the material is driven to move by friction between the blade and the material during normal operation so as to realize conveying of the material; friction can be generated between the screw blade and the barrel body, which can damage the screw blade gradually; but since the screw blade is of an integral structure, so that the whole blade fails when a part of the blade is damaged; and the blade needs to be changed, so that waste of manpower and material resources is caused. For solving the defect in the prior art that the whole blade is scrapped because of partial failure, a combined-type blade is adopted by the invention; the original integral blade is changed into two parts, namely a main body part and an easy-to-damage part; when the blade is abraded and fails, the blade can be conveniently repaired and changed; the later-period repair and maintenance cost is lowered; waste is reduced; and by adopting the combined-type blade, requirements on every aspect of use of the blade are met, and the use property is unchanged.

Owner:SHANDONG HAINENG ENVIRONMENT TECH CO LTD

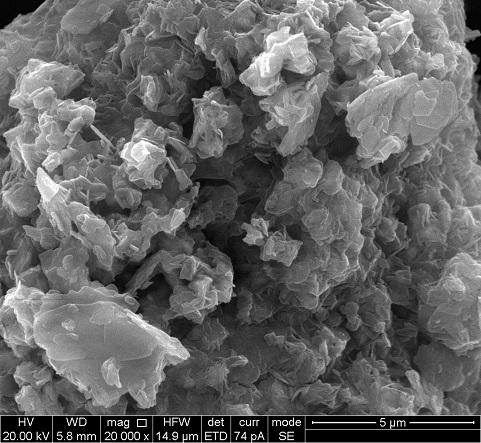

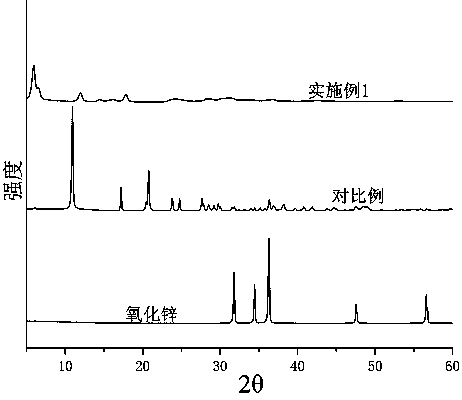

Vulcanizing activator and preparation method thereof

The invention relates to a vulcanizing activator and a preparation method thereof. The vulcanizing activator is prepared by the following steps: putting zinc oxide, benzoic acid and an alkane solventof which the boiling point is 100-150 DEG C into a reaction container in a mass ratio of 1:(0.05-0.1):(3-6), stirring for 30 minutes, adding glycerinum in a mole ratio to the zinc oxide of 1:(1.15-1.2), heating to 100-150 DEG C under stirring, enabling the components to react for 120-180 minutes, cooling, carrying out suction filtration, and drying a filter cake, thereby obtaining the vulcanizingactivator, wherein the content of zinc in the vulcanizing activator is 45-47%. The vulcanizing activator provided by the invention is capable of replacing zinc oxide in an equal mass fraction and hasa remarkable zinc reduction effect. The vulcanizing activator is simple in preparation method, convenient to operate and gentle in reaction condition.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

Glass-reinforced-plastic counterweight protective guard for elevator and production process thereof

ActiveCN103909704AHigh strengthThe effect remains the sameLamination plant layoutSynthetic resin layered productsPolyesterGlass fiber

The invention discloses a glass-reinforced-plastic counterweight protective guard for an elevator. The glass-reinforced-plastic counterweight protective guard comprises the following materials in percentage by weight: 52-58% of unsaturated resin, 32-38% of glass fiber, 4.6-5% of a curing agent, 0.1-0.3% of polyester film, 2.5-3.5% of a promoter and 1.5-2.5% of a pigment. The invention also discloses a production process of the glass-reinforced-plastic counterweight protective guard for the elevator. The production process comprises the following steps: (1) taking the materials and manufacturing resin adhesive solution; (2) laying the resin adhesive solution on the polyester film; (3) adding the glass fiber; (4) soaking and covering with an upper film; (5) entering an oven for heating, curing and forming; and (6) shaping, cooling and then cutting. The production process disclosed by the invention has the advantages that a continuous mechanism is adopted for forming, and the upper film and a lower film are adopted for covering, so that the pollution to the environment can be reduced, the performances such as aging resistance, impact resistance, tear resistance and water resistance of a product are improved, scratching is not caused in the installation process. The glass-reinforced-plastic counterweight protective guard is suitable for being used in a pit of an elevator hoistway.

Owner:XUANCHENG VALIN PRECISION TECH

Process for treating high-purity pyridine solution

InactiveCN101074211BEasy to operateMild conditionsOrganic chemistryWater contaminantsHigh concentrationBiodiesel

Process for treating high-concentration pyridine aqueous solution is carried out by boiling while distilling for high-concentration pyridine aqueous at constant temperature continuously, delivering itto top of tower to obtain pyridine-constant-hydrated boiling substances, circulation utilizing, hierarchical extracting 1-10 times with coarse pyridine biological diesel-oil as extracting solvent atnormal temperature, or countercurrent extracting continuously in proportion of solvent: waste water=5:1-1:10 and pH=4-10 for 3-30 mins, laying aside for 5-15 mins, separating, decompress distilling for extracting phase containing pyridine and biological diesel-oil, and recovering pyridine and biological diesel oil. It's simple, economical and has better effect and no environmental pollution.

Owner:ZHEJIANG UNIV OF TECH

Injection mold rotation non-destructive thread removal mechanism

InactiveCN102294799AAvoid damageReduce extrusion pressureScrew-threads articlesHydraulic motorEngineering

Injection mold rotates without damaging thread removal mechanism, including mold template, mold core is installed on the template, there is plastic product on the mold core, plastic product is threaded, hydraulic motor is installed on one side of the template, the hydraulic motor is connected to the threaded core through the keyway, The head of the threaded core matches the thread of the plastic product, and is characterized in that a bracket is installed on the template, a threaded sleeve is installed in the bracket, and an external thread is formed on the tail of the threaded core, and the external thread matches the threaded sleeve. In this solution, when the hydraulic motor drives the threaded core to rotate and pull the core, the reaction force for the threaded core to withdraw is borne by the external thread and the threaded sleeve, which reduces the extrusion force of the threaded core when it exits the thread of the plastic product, and makes the thread of the plastic product No damage, improve yield and save cost. Moreover, the structure is simple, the processing is easy, and it is suitable for all plastic products with threads, and has a wide range of applications and significant positive effects.

Owner:ZHEJIANG KAIHUA MOLDS

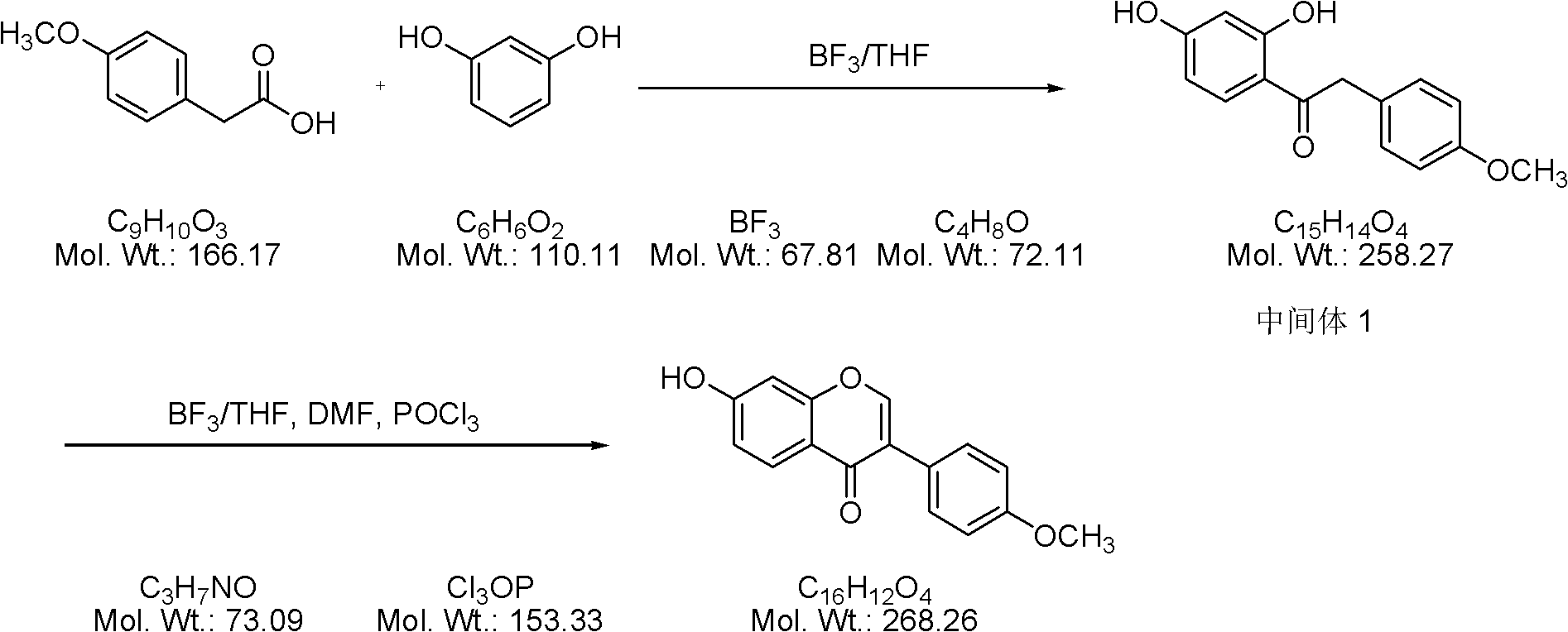

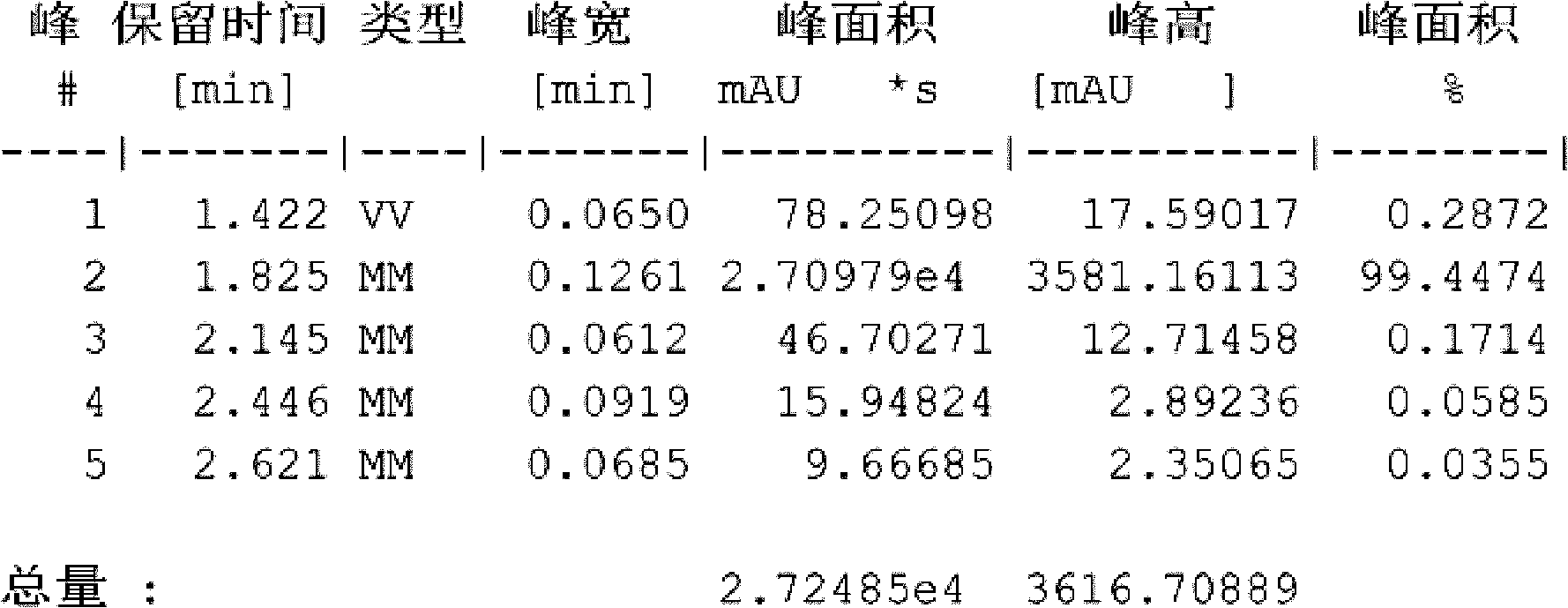

Method for synthesizing formoononetin

InactiveCN102002030AReduce manufacturing costThe effect remains the sameOrganic chemistryChemistryBoiling point

The invention relates to a method for synthesizing formoononetin, which comprises the steps of: carrying out condensation and cyclization reaction on p-methoxyphenylacetic acid and hydroxyphenol, which are used as raw materials; and then purifying the materials to obtain the product formoononetin. The method for synthesizing formoononetin, provided by the invention is characterized in that in the first step of condensation reaction, boron triflouride-tetrahydrofuran is used for replacing boron triflouride-diethyl ether in the prior art to be used as a solvent, and because the boiling point and the safety of the tetrahydrofuran are far higher than those of the diethyl ether, the industrialized large-scale production becomes possible; and a water-methanol mixed solvent is used for product purification in the first step so as to replace a pure methanol or pure ethanol solvent in the prior part, therefore, the production cost can be obviously reduced and the effect is the same. In addition, the water-methanol mixed solvent is also used for product purification in the last step to replace the pure methanol or pure ethanol solvent in the prior part, so that the total cost can be further reduced. Moreover, the synthesizing method also has the advantages of simplicity in operation, convenience, high safety and the like.

Owner:天津市佰斯康科技有限公司

Preparation method of ultra-thin woven fabric with anti-ultraviolet photocatalytic antibacterial and waterproof function

InactiveCN107675326BWaterproof Stability GuaranteeImprove functionalityWoven fabricsMonocomponent polyesters artificial filamentPolyesterFiber

The invention provides a method for preparing an ultra-thin woven fabric with anti-ultraviolet photocatalysis, antibacterial and waterproof functions, which includes weaving, shaping, finishing and molding; the fiber raw materials used in the weaving include anti-ultraviolet and antibacterial polyester or nylon. The product obtained by the method of the invention can simultaneously have three excellent functional effects of anti-ultraviolet / antibacterial and waterproof. In terms of anti-ultraviolet, the ultraviolet protection factor (UPF) value can reach 100, reaching the highest anti-ultraviolet standard UPF value of 50+, which is about 100% higher than other methods, and the antibacterial effect can reach 99% under photocatalysis (sunlight) %, at the same time, it can also stably ensure that the waterproof level of the fabric is 4.

Owner:苏州白云纺织科技发展有限公司

Blank supplying and automatic bottle shedding mechanism of plastic blowing machine

InactiveCN101544054BIncrease productivityReduce labor intensityHollow articlesEngineeringPlastic bottle

Owner:蔡业

A cationic dye dyeing wastewater decolorizer and its preparation and use method

ActiveCN106348358BRealize resource utilizationAvoid secondary pollutionWater contaminantsWater/sewage treatment by sorptionWater basedPumice dust

Owner:QINGDAO UNIV

A method for separating and purifying lentinan

InactiveCN101161112BThe effect remains the sameAdapt to mass industrial productionFungi medical ingredientsFood preparationElutionChromatographic column

The present invention relates to a method for separating and purifying lentinan, which is characterized in that after transforming the column type of the traditional chromatographic column to heterotype column, the lentinan coarse product is pretreated so as to ensure it to adopt the absorption of the heterotype column, the separating and purifying of the lentinan is changed to that of the lentinan dynamicly and high efficiently, thus to obtain single lentinan after a series of treatment of washing, elution, dialysis, deposition and freeze out etc. The advantage of the present invention is that it is suitable for producing large quantities and industrialisation, and can obtain high effect, low cost product with the precondition of method is simple as well as quality is good.

Owner:上海慈瑞医药科技股份有限公司

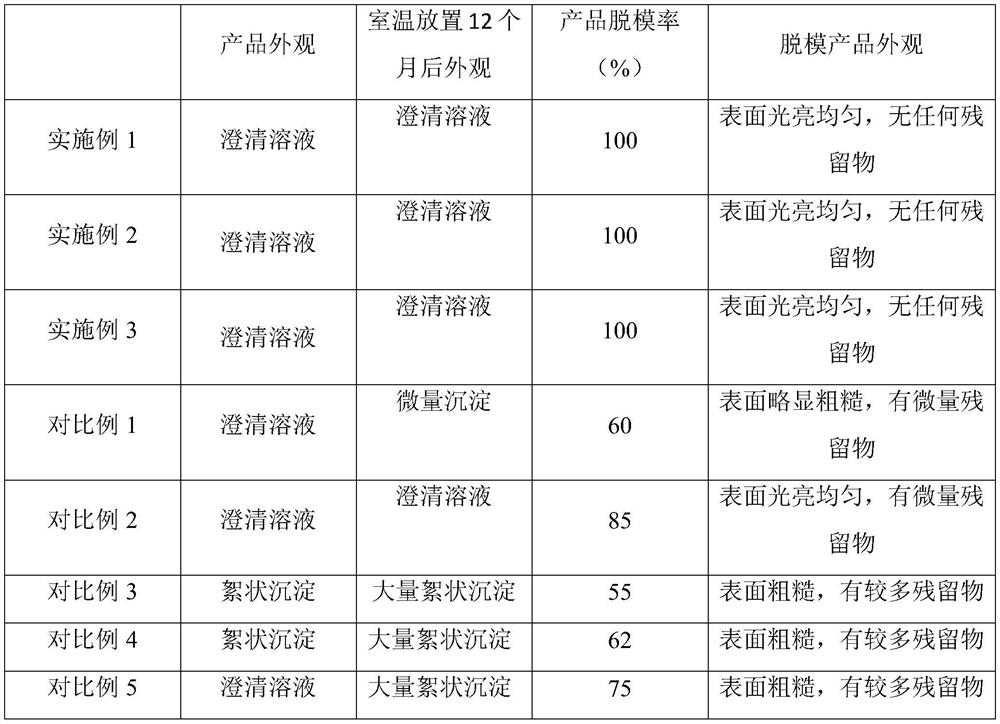

A spray-on plastic release agent

A spray-on plastic release agent, which is composed of A solution, B solution, C solution and D solution according to the volume ratio of 15~35:1.6:0.5:0.8~1; the A solution is prepared by the following method Preparation: get 100ml ethyl acetate, 15ml eucalyptus oil and 3ml glycerol carbonate and mix it; the B solution is made by mixing 100mL ethyl acetate and 15mL eucalyptus oil; the C solution is 10mL simethicone Prepared by dissolving in 100mL ethyl acetate; the D solution is a mixed surfactant solution prepared by dissolving 10g sodium stearate and 10g Tween-80 in 100mL water. The mold release agent is used for mold release of plastic products and has good smoothness, isolation and mold release, high and low temperature resistance, chemical stability, no corrosion, non-toxic environmental protection, easy operation, and good use effect.

Owner:上海济雨实业有限公司

A gynecological biological agent

ActiveCN106552078BImprove immunityImprove mental stateHydroxy compound active ingredientsAntipyreticCelluloseChlorhexidine Acetate

The invention relates to the field of the medical technology, in particular to a multifunctional biological preparation. The multifunctional biological preparation comprises the following components comprising, by mass, 831-856 parts of water, 50 parts of glycerin, 50 parts of propylene glycol, 6 parts of carbomer, 0-6 parts of radix sophorae flavescentis extract, 5 parts of houttuynia cordata extract, 1-2 parts of chitin, 10 parts of cellulose, 5-20 parts of motherwort extract, 0-1 part of hyaluronic acid, 5 parts of borneol, 0-3.5 parts of ethyl alcohol, 1 part of chlorhexidine acetate, 0-0.5 part of peppermint oil and 0-20 parts of common cnidium fruits. The multifunctional biological preparation can significantly improve the immunity, especially the immunity of the genital system and significantly relieve the dysmenorrheal symptom. The multifunctional biological preparation can significantly improve the health state and the youthful state of the genital system and comprehensively solve various genital problems.

Owner:GUANGZHOU GREEN HUMAN BIOTECH

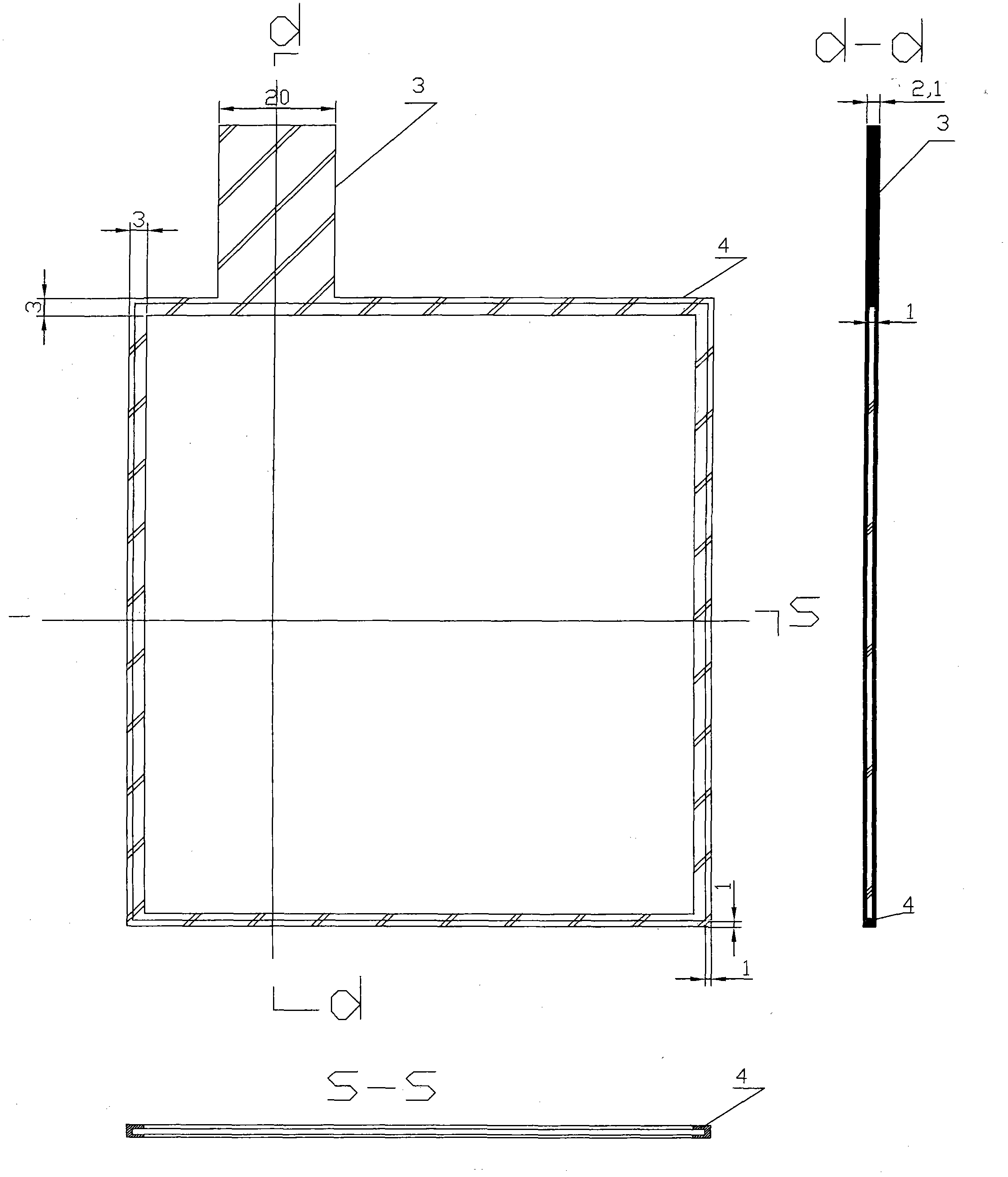

Lead-acid accumulator assembled by pole plate with frame-cast, screened and pasted lead-plastic compound grid

InactiveCN102501464BGuaranteed electrical conductivityConductiveFinal product manufactureElectrode carriers/collectorsElectrochemical responseElectrical conductor

A lead-acid accumulator assembled by a pole plate with a frame-cast, screened and pasted lead-plastic compound grid is disclosed. Because of the utilization of a plastic grid which has no problem of oxidative deterioration due to no participation in electrochemical reaction in an environment that the accumulator is repeatedly charged and discharged for a long time, the long-time stable existence of the grid is ensured. Lead foils glued and compounded on the two surfaces of a plastic matrix are converted to a lead dioxide conductor after electrochemical oxidization, and the conductor is firmly attached to the plastic matrix to keep stable under the powerful action of an adhesive. The two stabilizations ensure the long-time conductive function of the grid and the long-time stable and invariable grid-shaped structure of the grid, and active substances attached to the grid are impossible to fall off due to the support of the grid and the protection of a mesh; and because of no falling-off of the active substances of positive pole, the scrapping conditions of the lead-acid accumulator are inexistent, and the service life of the accumulator can be greatly prolonged due to the long-time stable existence of a positive plate.

Owner:李平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com