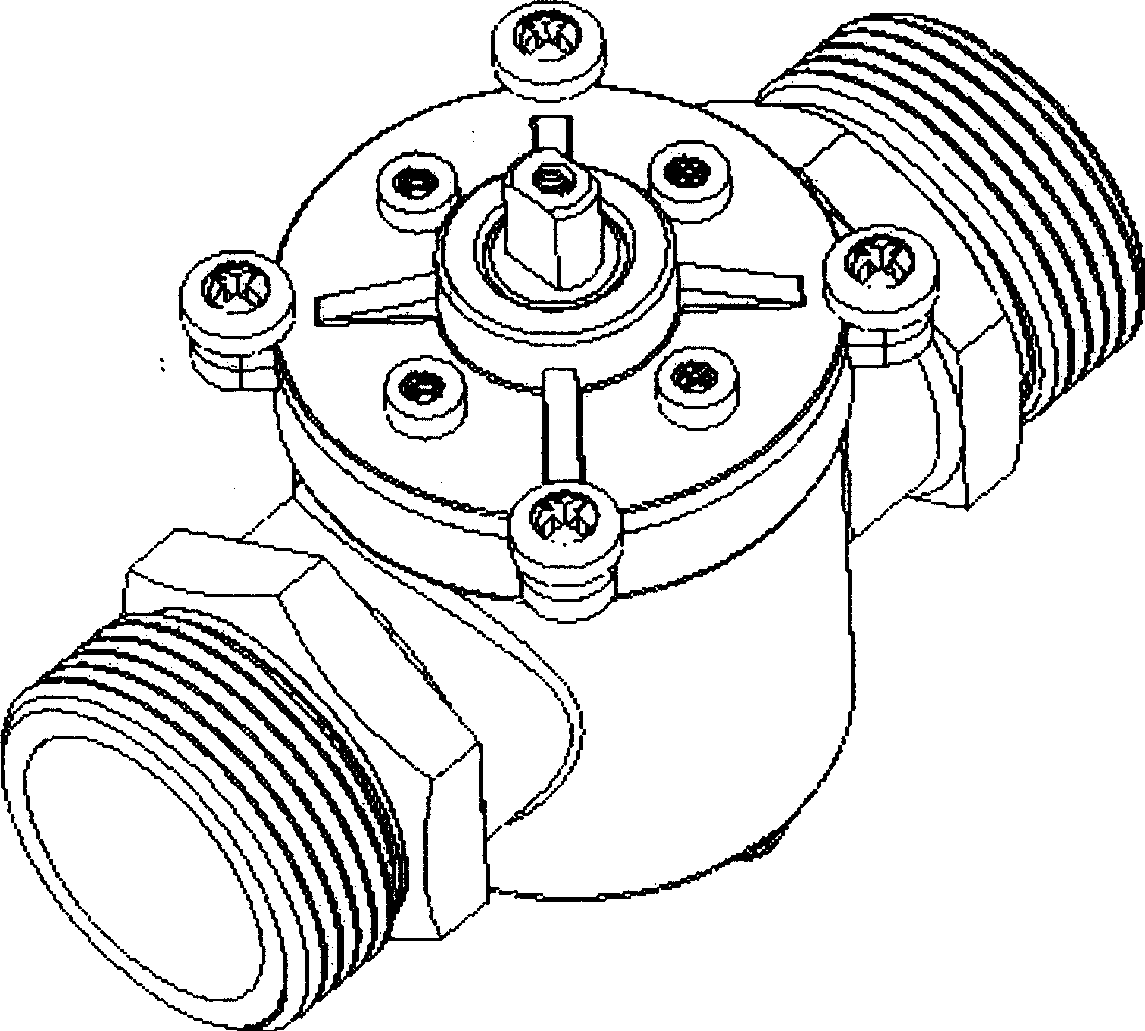

Upper assembled electric ball valve

A technology for electric ball valves and top loading, which is applied in the direction of valve devices, engine components, cocks including cut-off devices, etc. It can solve the problem that it is not enough to make up for the sealing and performance defects, and the misalignment of the ball and spherical sealing rings and the rotating shaft is difficult to solve Sealing performance and other issues, to achieve a wide range of application prospects and promotion of use value, control accuracy and switch performance is stable and reliable, to ensure the effect of mechanical strength and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

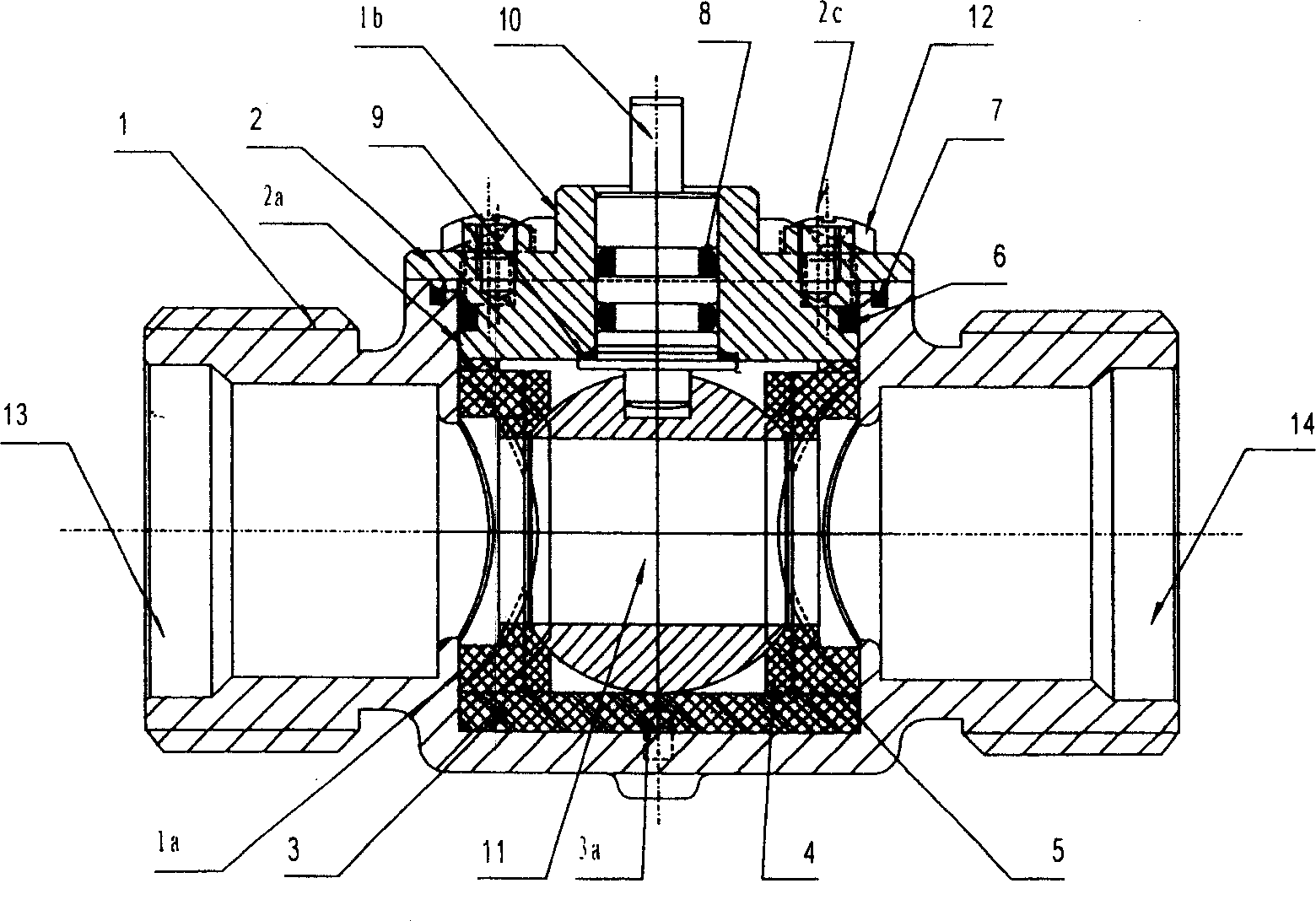

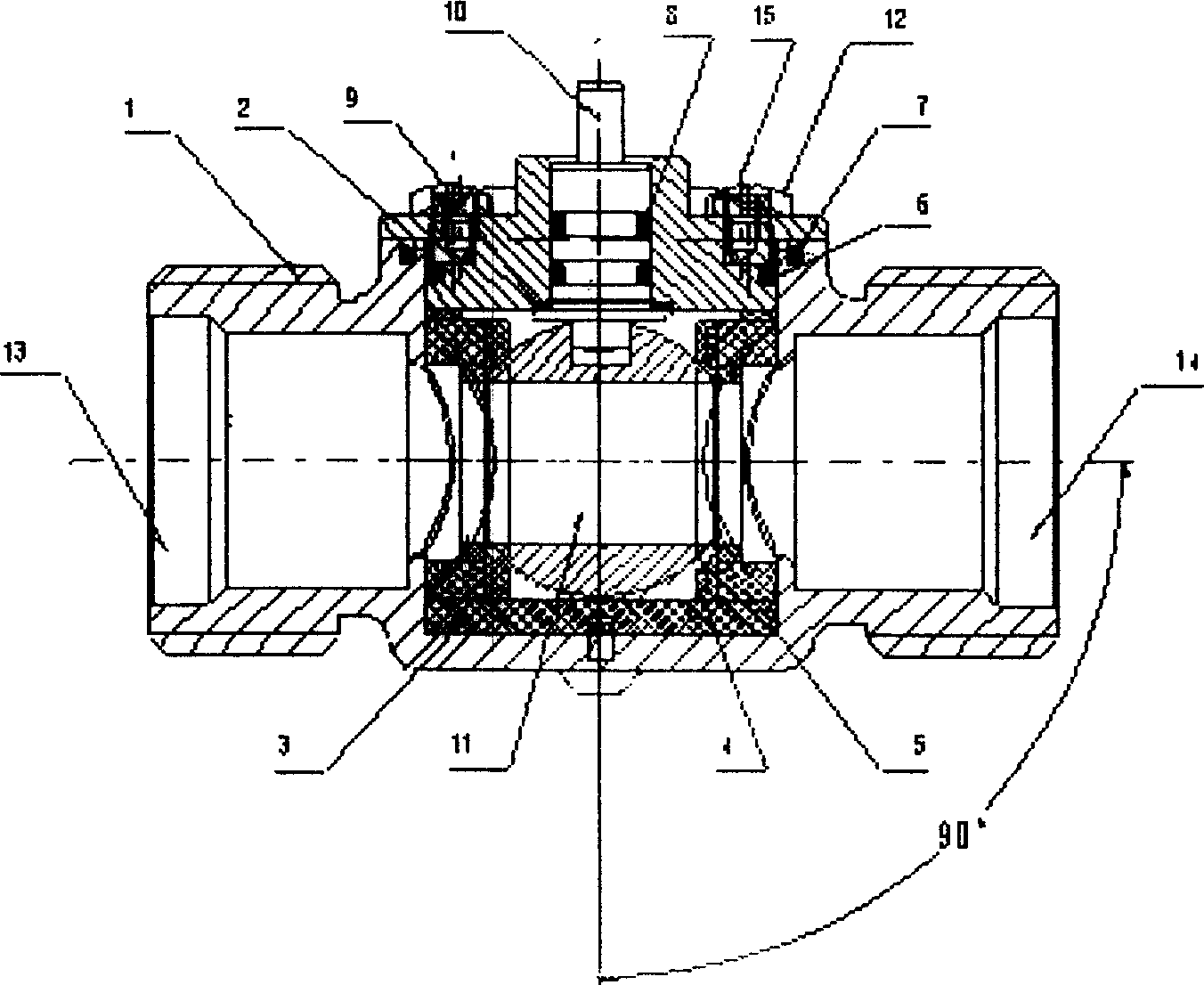

[0035] Embodiment: A convenient top-mounted electric ball valve for disassembly (see Figure 1-3 and 5), comprising a ball valve body 1, a ball valve upper cover 2, a valve core 3, a water inlet 13, a water outlet 14 and an electronic control unit, and is characterized in that a special-shaped spherical sealing ring 4, a silicon rubber elastic sealing ring are arranged in the valve core 3 5. O-shaped sealing ring I6, O-shaped sealing ring II7, O-shaped sealing ring III8, polytetrafluoroethylene wear-reducing washer 9, rotating shaft 10, sphere 11 and fastening screw 12 form a detachable ball valve core assembly. Upper cover 2, valve core 3, special-shaped spherical seal ring 4, silicone rubber elastic seal ring 5, O-ring seal I6, O-ring seal II7, O-ring seal III8, polytetrafluoroethylene anti-friction washer 9, rotating shaft 10. The assembly of the ball 11 and the fastening screw 12 is perpendicular to the axis of the water supply pipeline (see attached image 3 ), that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com