Blank supplying and automatic bottle shedding mechanism of plastic blowing machine

A stretch-blow machine and plastic technology, which is used in the fields of plastic hollow containers, plastic stretch-blow machines, preforms, and automatic ejection of bottles, which can solve the problems of being easily crushed by molds, low production efficiency, and high labor intensity. , to avoid die rolling, high production efficiency and low labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

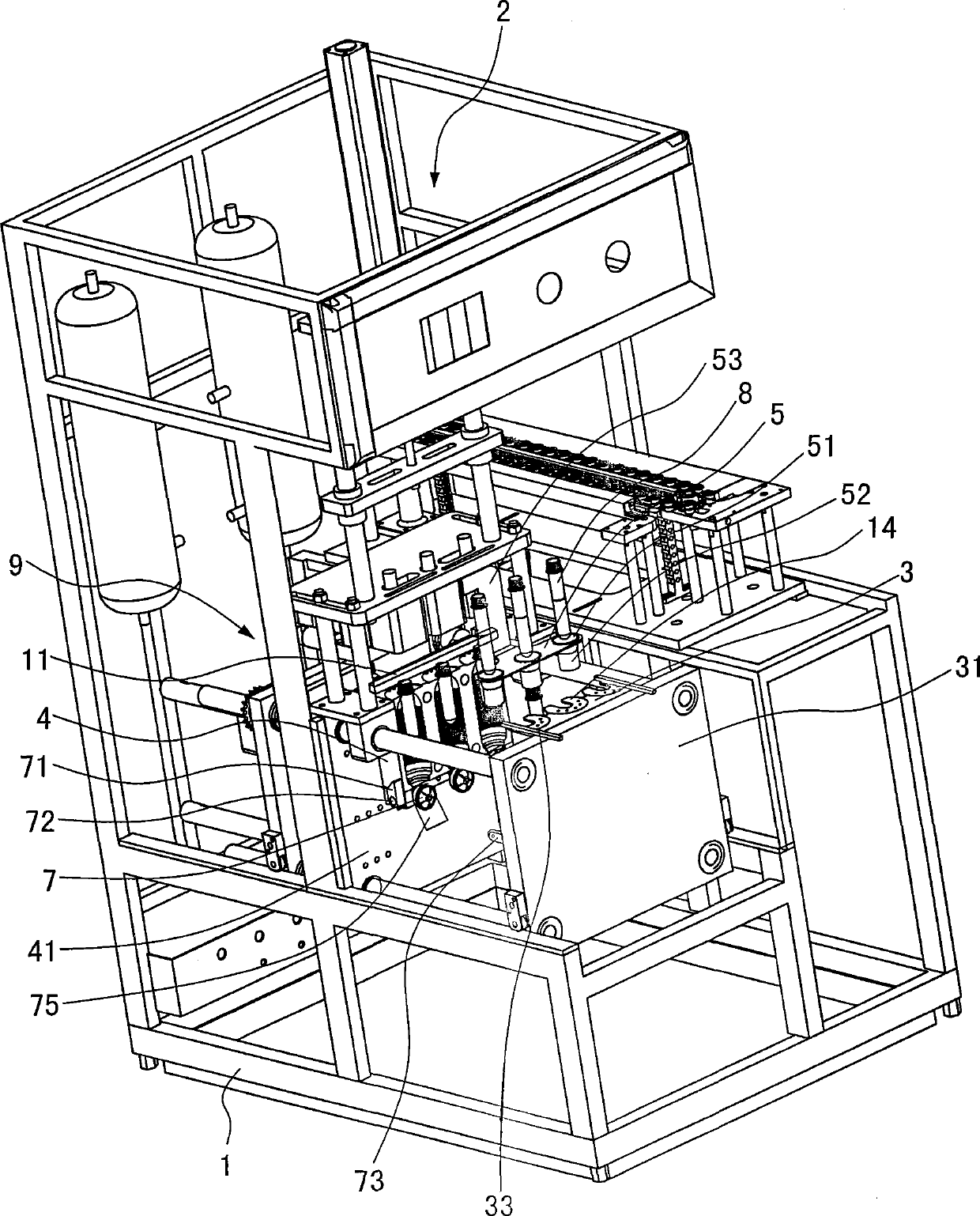

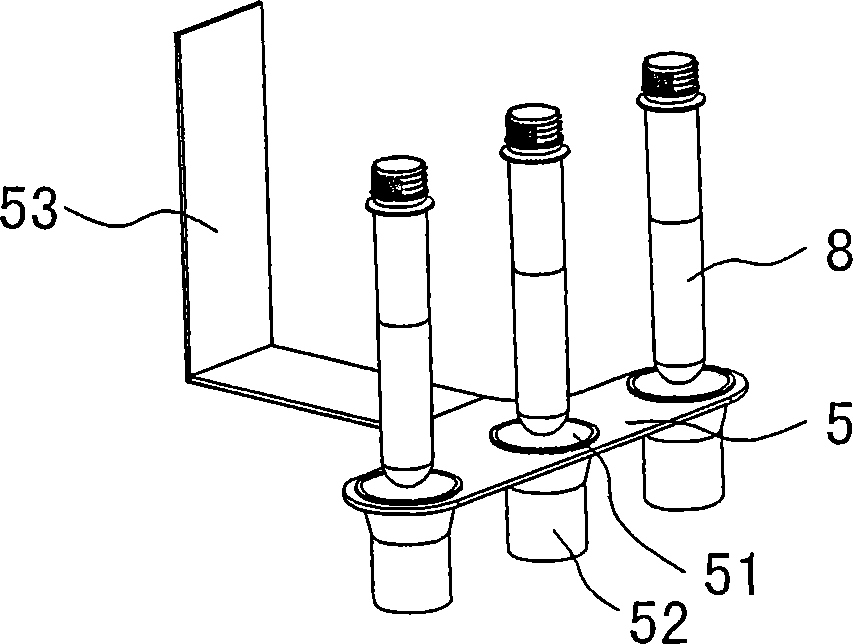

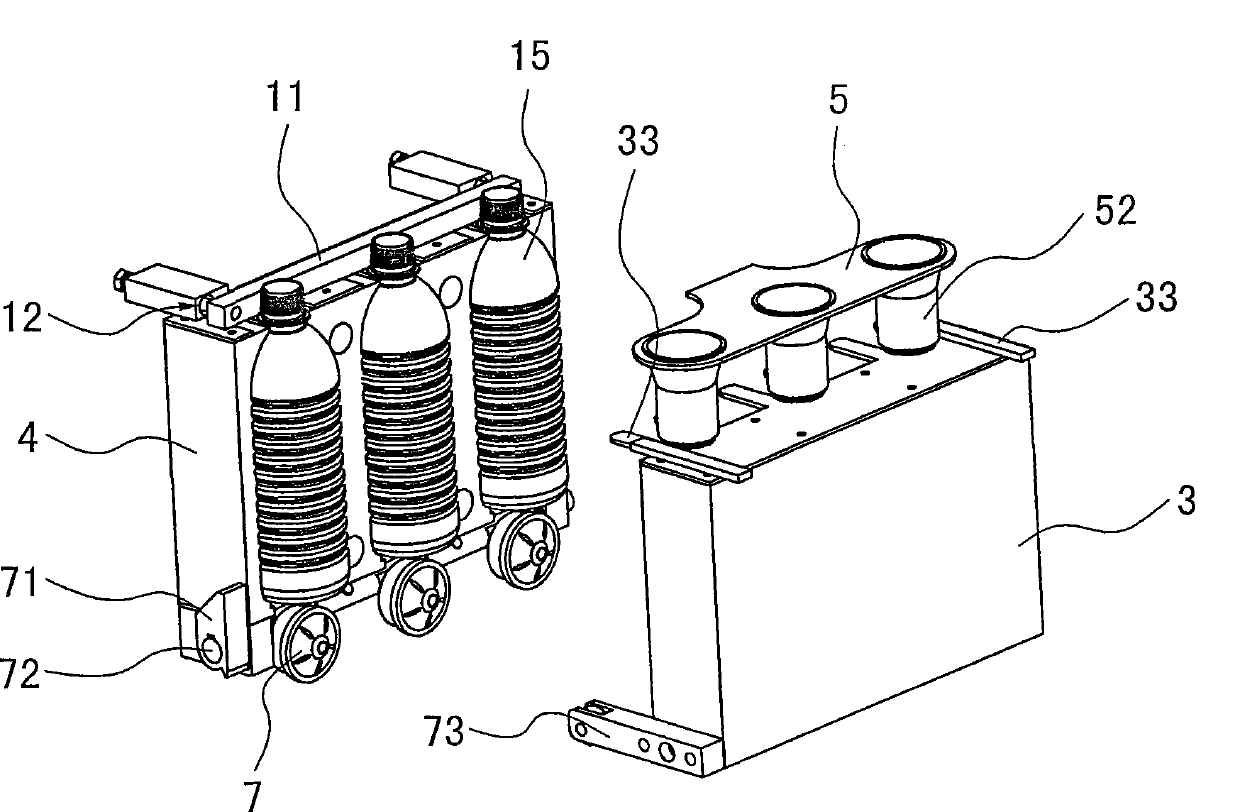

[0023] The invention relates to a preform and an automatic bottle-removing mechanism of a plastic stretch-blow machine, such as Figure 1-Figure 5 , Figure 13 , Figure 14Shown, comprise frame 1, install fixed formwork 41 and movable formwork 31 in the frame 1, mold is arranged in the formwork, comprise the mold opening and closing mechanism 9 that cylinder and connecting rod etc. are formed, the front formwork of this scheme is movable formwork 31, The movable mold 3 moves inside and outside along with the movable template 31. There is a stretch-blow mechanism 2 on the frame 1, and at the same time, the heating device can be installed on one side of the stretch-blow machine. For example, it can be on the same frame and the distance is close Some. The main feature is that the mold is equipped with a preform loading device and an automatic bottle removal mechanism, but the preform loading device of this program is not an automatic preform loading by a manipulator, but also a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com