Shaftless screw conveyor

A shaftless screw conveying and screw blade technology, applied in the field of screw blades, can solve problems such as irreparability, blade failure, waste of manpower and material resources, and achieve the effect of reducing maintenance costs, maintaining the same performance, and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to illustrate the technical solution of the present invention more clearly, the following specific embodiments will introduce the present invention in detail in conjunction with the accompanying drawings.

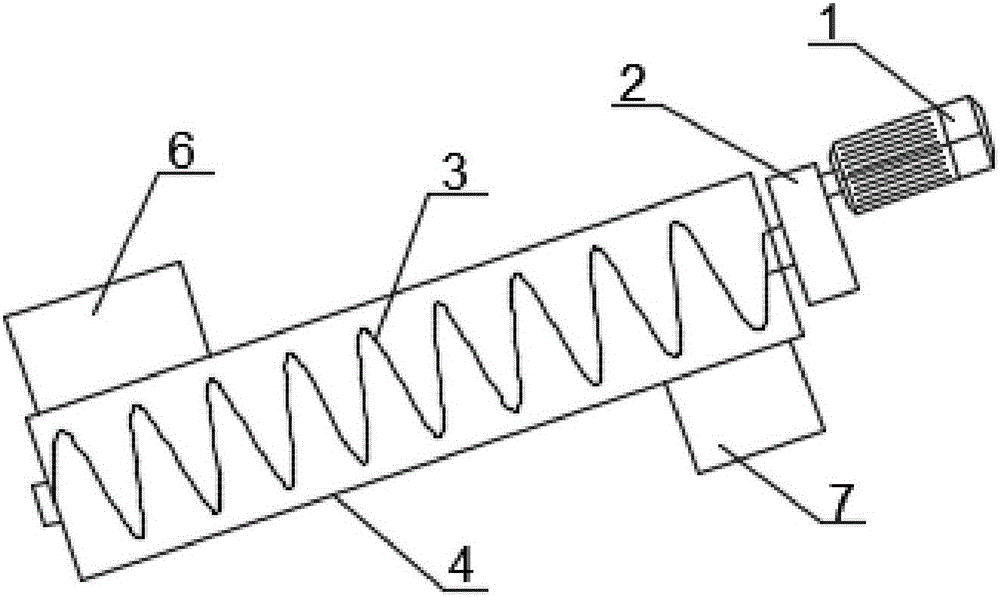

[0018] Such as Figure 1~4 As shown, a shaftless screw conveyor includes: a motor (1), a reducer (2), a screw blade (3), a cylinder (4), a liner (5), an inlet (6), an outlet (7); Wherein, cylinder body (4) one side is provided with feed inlet (6), and the other side is provided with discharge outlet (7), and motor (1) is connected with reducer (2) and is arranged on cylinder body (4) ) side, the integral structure of the screw blade (3) runs through the inside of the cylinder (4), the screw blade (3) is connected with the drive shaft of the reducer extending into the inside of the cylinder, and the liner (5) is arranged on the cylinder (4 ) inner wall.

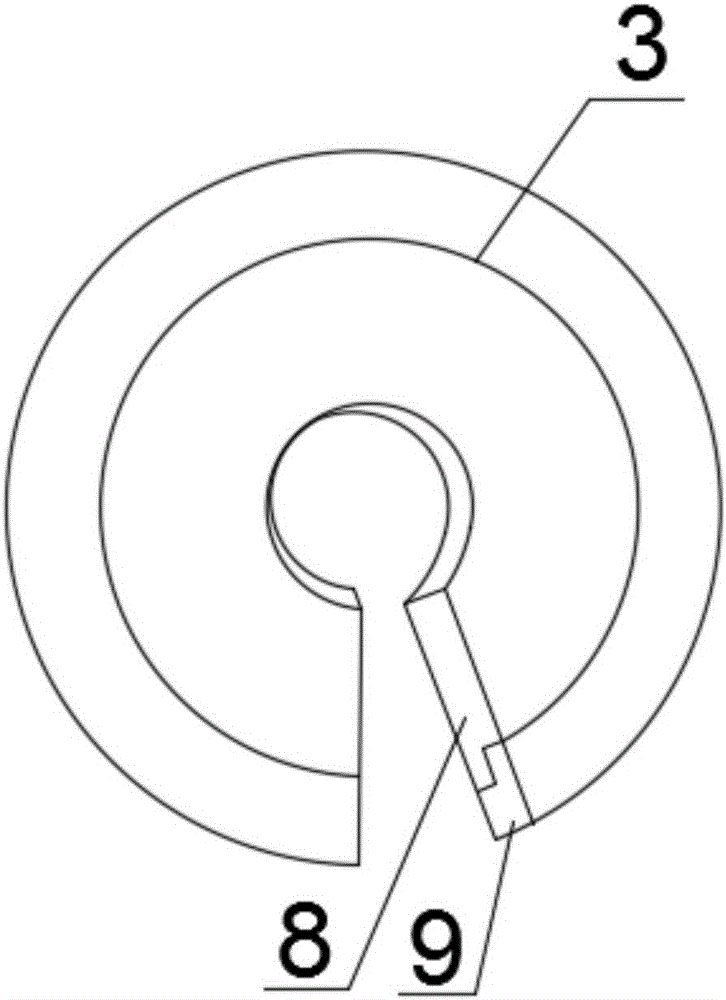

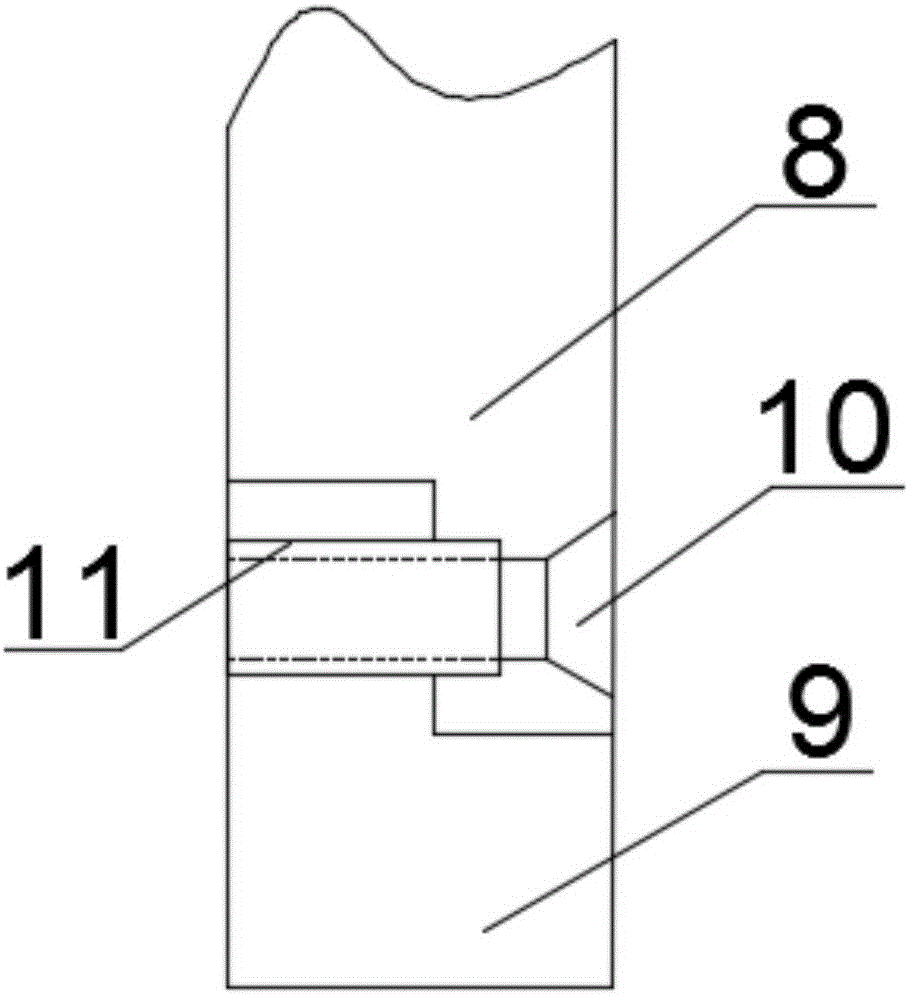

[0019] Such as figure 2 As shown, the spiral blade (3) includes: a main body part (8), a vulnerable p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com