Lead-acid accumulator assembled by pole plate with frame-cast, screened and pasted lead-plastic compound grid

A technology of acid battery and composite plate, applied in lead-acid battery, lead-acid battery construction, electrode carrier/current collector, etc., can solve the problems of loss of use function of battery, oxidation of positive grid, short life of lead-acid battery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

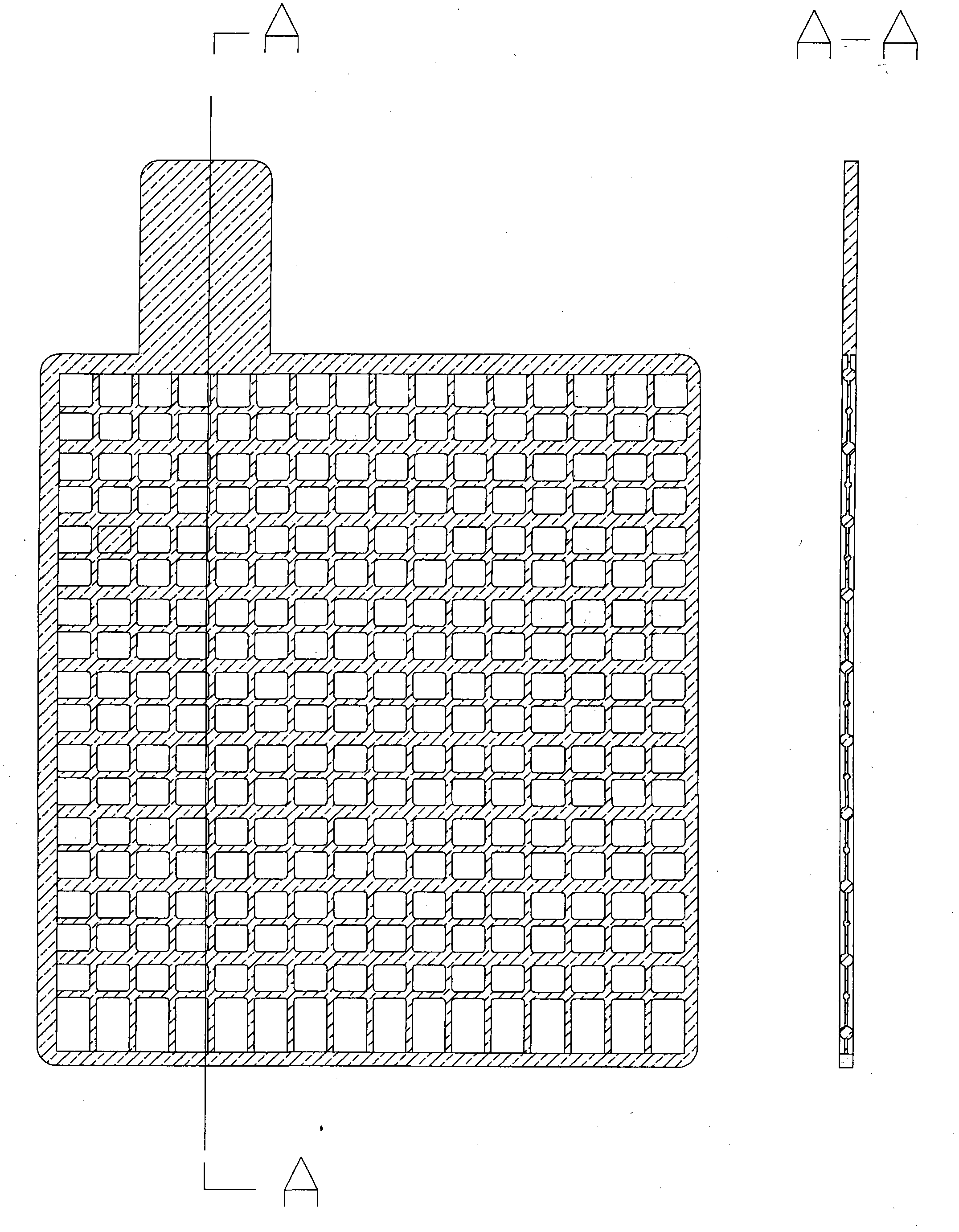

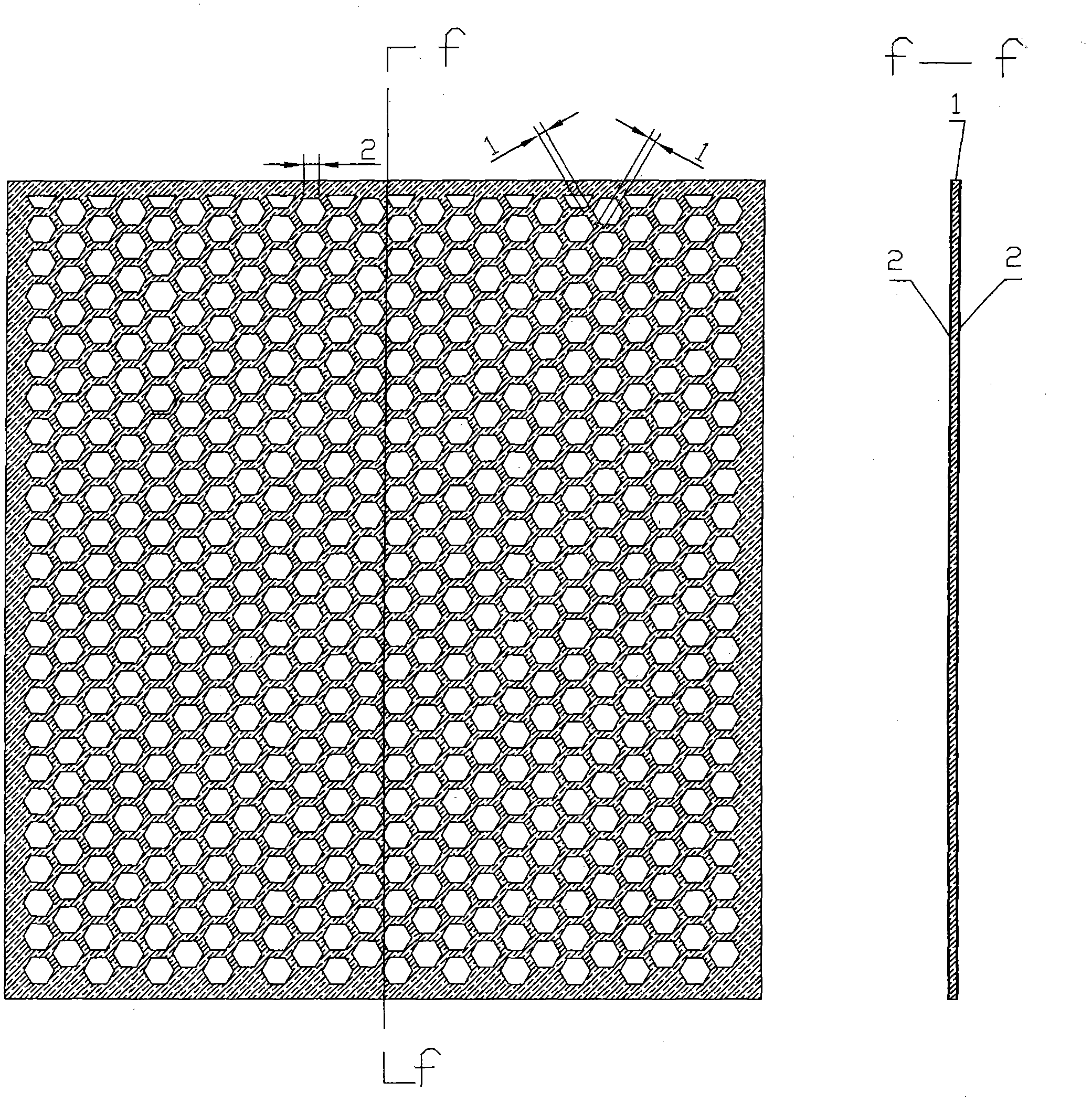

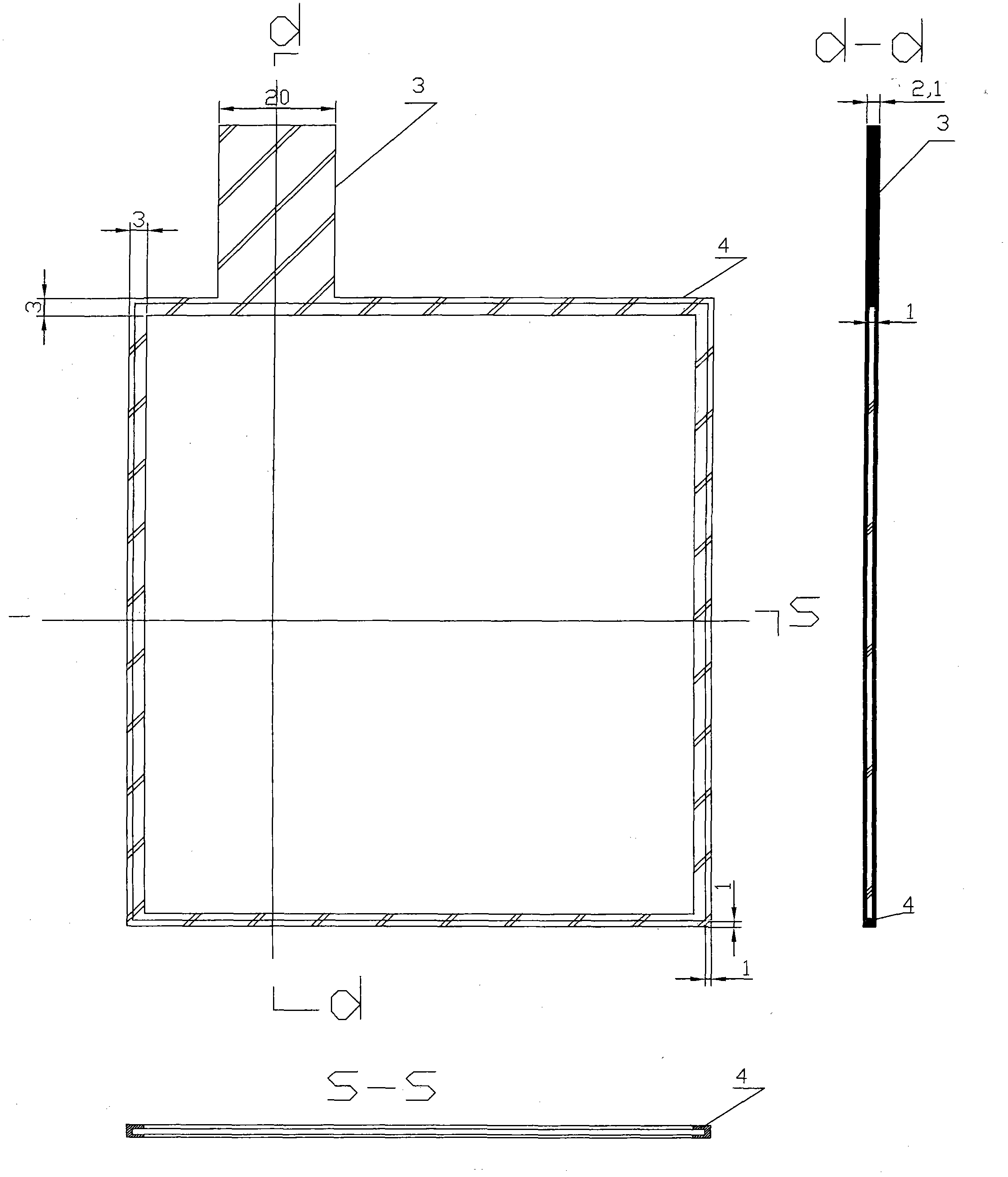

[0010] First of all, we use 500mm wide and 1mm thick polytetrafluoroethylene rolled sheet, 500mm wide and 0.10-0.15mm thick rolled lead foil coil, and carry out single-sided glue coating on the laminating machine to make single-sided lead plastic. Composite sheet. Turn it over and use a rolled lead foil coil with a width of 500mm and a thickness of 0.10-0.15mm on the other side of the thin plate for glue coating and compounding to make a three-layer composite board. Then cut into slices according to certain specifications. Install the designed die on the punching machine to punch out the shaped lead-plastic composite grid. As shown in Figure (2): the front of the grid is a geometric surface after washing out n regular hexagonal parts with a side length of 2mm. (1) is a polytetrafluoroethylene material, and its two sides (2) are calendered lead foils firmly compounded on it after gluing. Judging from the materials used, we have obtained a lead-plastic composite grid that is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com