Preparation method of ultrathin woven fabric with anti-ultraviolet-photocatalysis, antibacterial and water-proof functions

An anti-ultraviolet and anti-ultraviolet technology, applied in textile, fabric, rayon manufacturing, etc., can solve the problems of washing resistance, loss of elasticity, short energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

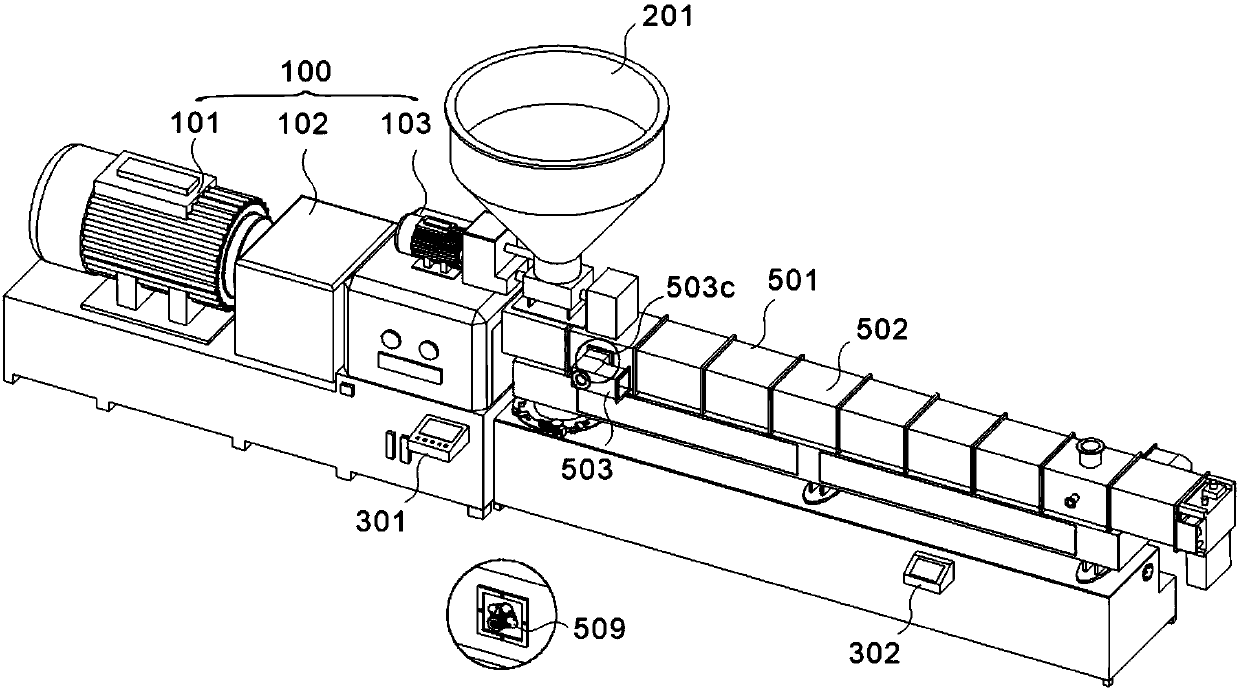

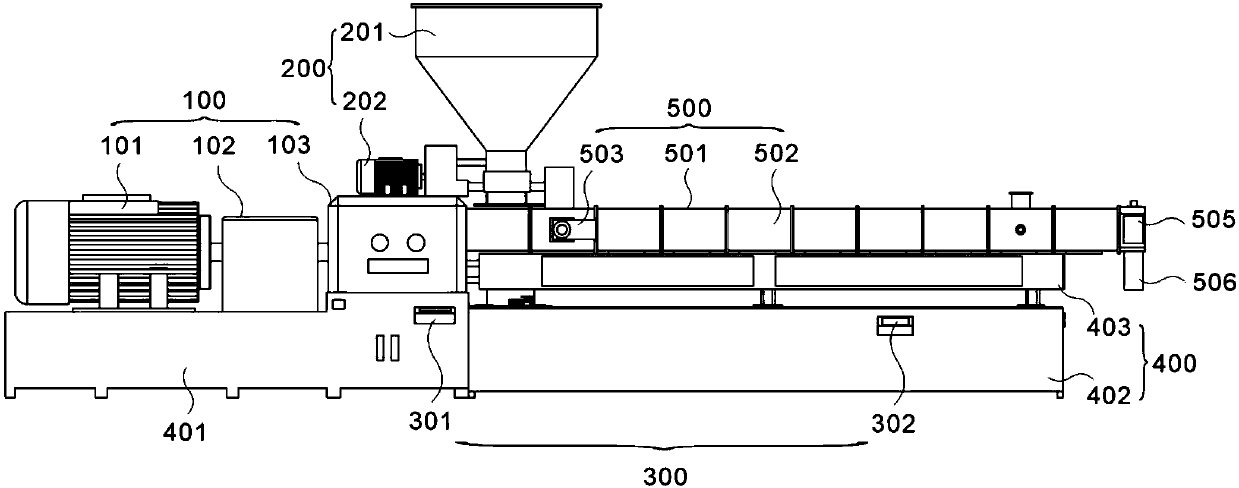

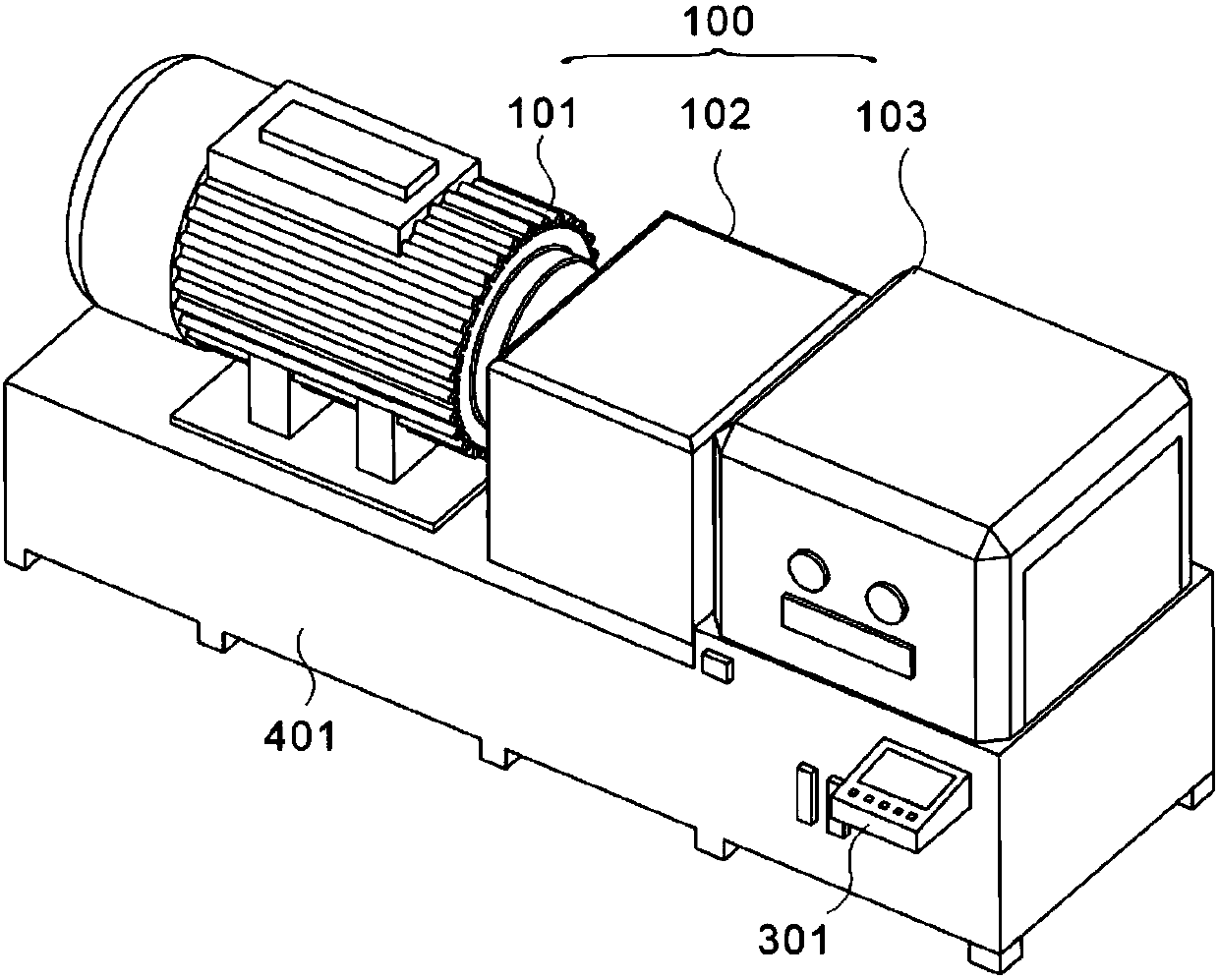

Image

Examples

Embodiment 1

[0042] With 20 parts by weight of polyester DTY and 80 parts by weight of anti-ultraviolet / antibacterial polyester DTY as fiber raw materials, the designed material is made through weaving, shaping, dyeing and finishing, and sewing processes. Anti-ultraviolet and antibacterial polyester is made of anti-ultraviolet and antibacterial functional masterbatch by anti-ultraviolet and antibacterial functional powder, which is prepared into anti-ultraviolet and antibacterial polyester by adding online masterbatch through spinning.

[0043] The anti-ultraviolet and antibacterial functional powder includes modified nitrogen-doped titanium dioxide. Its preparation process is,

[0044] Nitrogen-doped titanium dioxide with a nitrogen doping amount of 14% was placed under a UV lamp for 3 hours, and then placed in a 1.5% mass concentration of 3-(trimethoxysilyl)propyl-dimethyloctadecyl Put in the ammonium chloride solution for 5 minutes, take it out and place it at 90° C. for 12 hours to ob...

Embodiment 2

[0058] With 50 parts by weight of polyester DTY and 50 parts by weight of anti-ultraviolet / antibacterial polyester DTY as fiber raw materials, the designed material is made through weaving, shaping, dyeing and finishing, and sewing processes. Anti-ultraviolet and antibacterial polyester is made of anti-ultraviolet and antibacterial functional masterbatch by anti-ultraviolet and antibacterial functional powder, which is prepared into anti-ultraviolet and antibacterial polyester by adding online masterbatch through spinning.

[0059] The anti-ultraviolet and antibacterial functional powder includes modified nitrogen-doped titanium dioxide. Its preparation process is,

[0060] Nitrogen-doped titanium dioxide with a nitrogen doping amount of 15% was placed under a UV lamp for 3 h, and then placed in a 1.0% mass concentration of 3-(trimethoxysilyl)propyl-dimethyloctadecyl Put in the ammonium chloride solution for 4 minutes, take it out and place it at 95° C. for 10 hours to obtain...

Embodiment 3

[0073] With 80 parts by weight of polyester DTY and 20 parts by weight of anti-ultraviolet / antibacterial polyester DTY as fiber raw materials, the designed material is made through weaving, shaping, dyeing and finishing, and sewing processes. Anti-ultraviolet and antibacterial polyester is made of anti-ultraviolet and antibacterial functional masterbatch by anti-ultraviolet and antibacterial functional powder, which is prepared into anti-ultraviolet and antibacterial polyester by adding online masterbatch through spinning.

[0074] The anti-ultraviolet and antibacterial functional powder includes modified nitrogen-doped titanium dioxide. Its preparation process is,

[0075] Nitrogen-doped titanium dioxide with a nitrogen doping amount of 13% was placed under a UV lamp for 4 hours, and then placed in a 1.0% mass concentration of 3-(trimethoxysilyl)propyl-dimethyloctadecyl Put in the ammonium chloride solution for 5 minutes, take it out and place it at 90° C. for 11 hours to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com