C60 clathrate, and preparation method and application thereof

A technology of inclusion compound and C60, applied in the field of inclusion compound of fullerene-C60 and its preparation, can solve the problems of weak bearing capacity, reduced lubricating performance, unsatisfactory use effect, etc. The effect of dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The C of a kind of embedded dihydrocarbyl pentasulfide (RC2540) of embodiment 1 60 The preparation method of clathrate comprises the following steps:

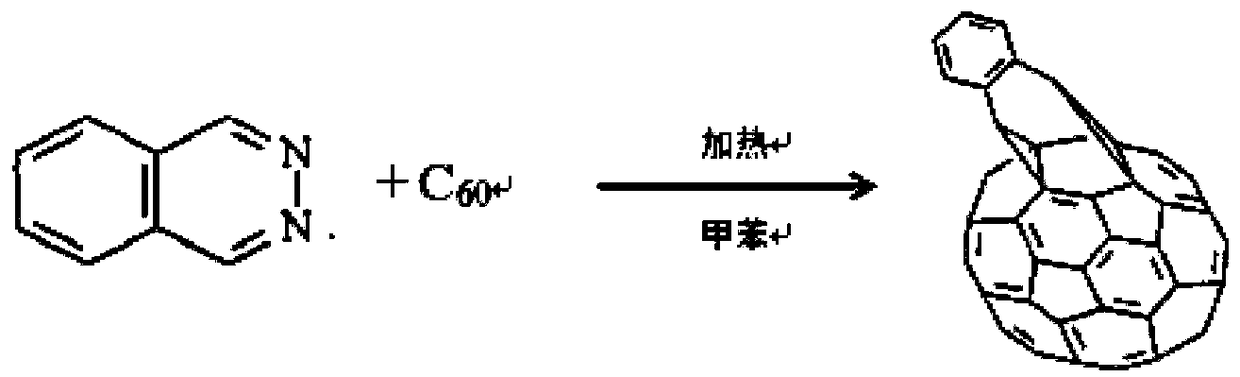

[0046] (1) Using the nitrogen method to convert C 60 Open the cage: first dissolve 15g of 2,3-naphthyridine (phthalazine) in 500ml of toluene, then add 2g of C 60 ; The mixed solution was heated to 80 ℃ under the condition of reflux 8h, utilize thin layer chromatography (TLC) tracking reaction, until the sample point does not change, the whole reaction continues 20h, the opening reaction process of this step is as follows figure 1 .

[0047] (2) On a rotary evaporator, the fully reacted mixed solution in the above (1) was subjected to vacuum distillation, and the heating temperature was 120° C. to obtain a concentrated solution.

[0048] (3) adopt silica gel column chromatography to separate and purify the concentrated solution in the above (2), adopt the mixed solution of toluene and sherwood oil as eluent, wherein ...

Embodiment 2

[0052] A kind of C with embedded sulfurized isobutylene (T321) of embodiment 2 60 The preparation method of clathrate comprises the following steps:

[0053] (1) Using the nitrogen method to convert C 60 Open the cage: first dissolve 15g of 2,3-naphthyridine (phthalazine) in 500ml of toluene, then add 2g of C 60 ; The mixed solution was heated to 80 ℃ under the condition of reflux 8h, utilize thin layer chromatography (TLC) tracking reaction, until the sample point does not change, the whole reaction continues 20h, the opening reaction process of this step is as follows figure 1 .

[0054] (2) On a rotary evaporator, the fully reacted mixed solution in the above (1) was subjected to vacuum distillation, and the heating temperature was 120° C. to obtain a concentrated solution.

[0055] (3) adopt silica gel column chromatography to separate and purify the concentrated solution in the above (2), adopt the mixed solution of toluene and sherwood oil as eluent, wherein the volu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com