Lubricating grease composition containing thiuram compound and preparation method thereof

A grease composition and compound technology, applied in the field of lithium-based grease, can solve problems such as poor effect, and achieve the effects of good extreme pressure and wear resistance, non-volatile and low odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The method for preparing the lubricating grease composition provided by the present invention comprises: mixing a thickener and a part of base oil, heating and heating, and then mixing with a thiuram compound, calcium petroleum sulfonate and the remaining base oil.

[0032] In the present invention, when the thickening agent is lithium fatty acid, the thickening agent can be synthesized in situ. Therefore, the method can include: in the presence of a part of the base oil, mixing a fatty acid and a lithium source, heating and heating, introducing The remaining base oil is cooled, and thiuram compounds and calcium petroleum sulfonate are introduced, and the temperature is continued, and optional additives are introduced. More specifically, the method may include: mixing part of the base oil and fatty acid, heating to 80-90° C., introducing an aqueous solution of a lithium source, stirring and raising the temperature, raising the temperature to 200-210° C., introducing the ...

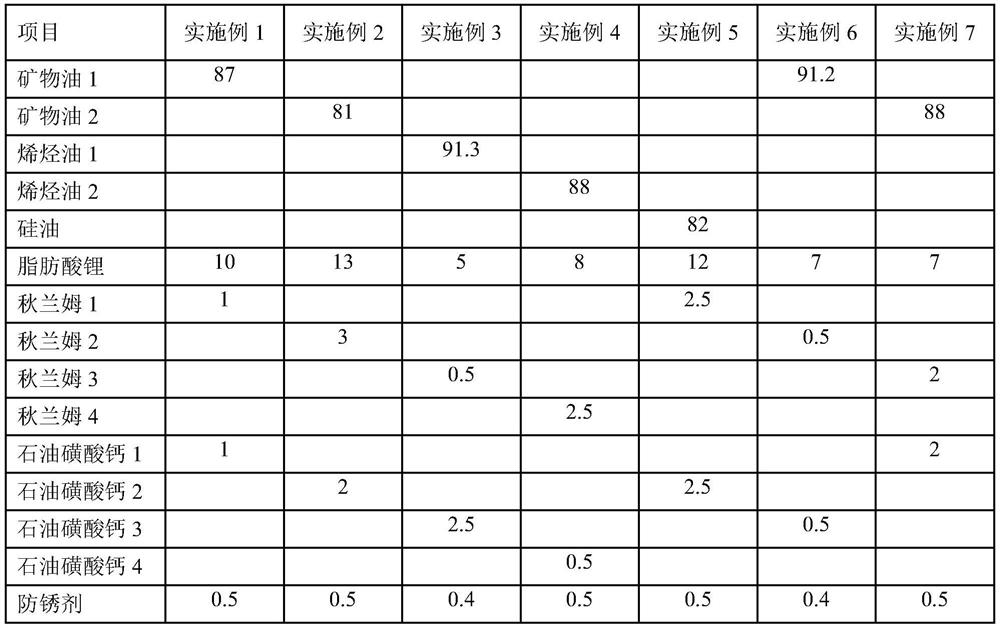

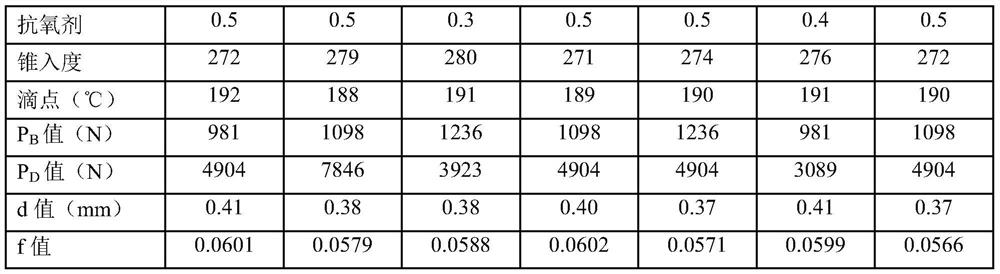

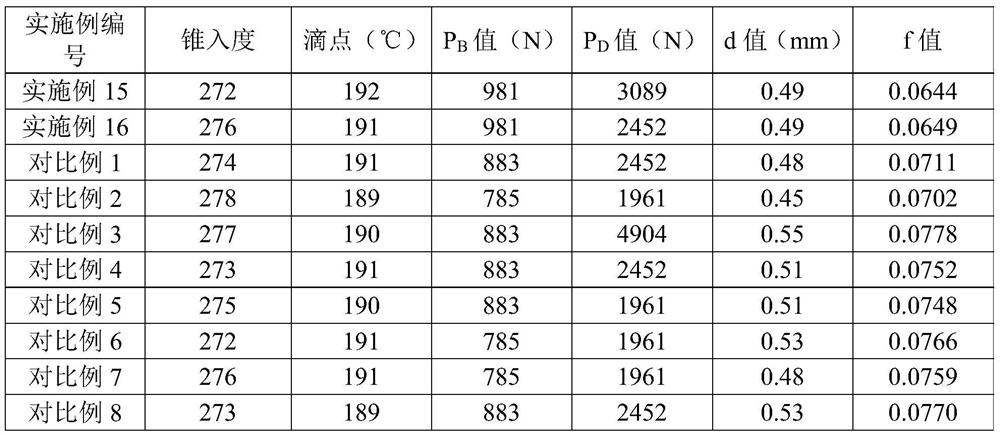

Embodiment 1-14

[0045] According to the proportioning shown in Table 1 and Table 2 respectively (accounting for the weight percent of the total weight of the grease composition, the calculation method of the fatty acid lithium is (the mass of the 12-hydroxy fatty acid / the molecular weight of the 12-hydroxy fatty acid × 12-hydroxy fatty acid lithium) molecular weight) / total weight of the composition × 100%, in the reactor, add base oil and 12-hydroxystearic acid with about 2 / 3 of the base oil consumption, heat up to 85±5°C, add lithium hydroxide aqueous solution , stir to heat up, the temperature rises to 205±5℃, add the remaining about 1 / 3 of the base oil, the material cools down, when the temperature drops to about 130℃, add thiuram compound and calcium petroleum sulfonate, stir for about 15min, Continue to lower the temperature to 85±5°C, add the remaining additives (rust inhibitor and antioxidant), and grind the material through three rounds of grinding to make it evenly dispersed to obtain...

Embodiment 15

[0047] A grease composition sample was prepared according to the method of Example 1, except that the thiuram compound was replaced by tetraisobutylthiuram disulfide (sulfur content 31.3% by weight).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com