Environment-friendly emulsified cutting fluid and method for preparing same

A kind of cutting fluid and affinity technology, applied in the direction of petroleum industry, additives, lubricating composition, etc., can solve the problems of smelly smell, environmental pollution, biodegradation, etc., achieve simple preparation method, protect clean environment, and protect normal The effect of benign operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

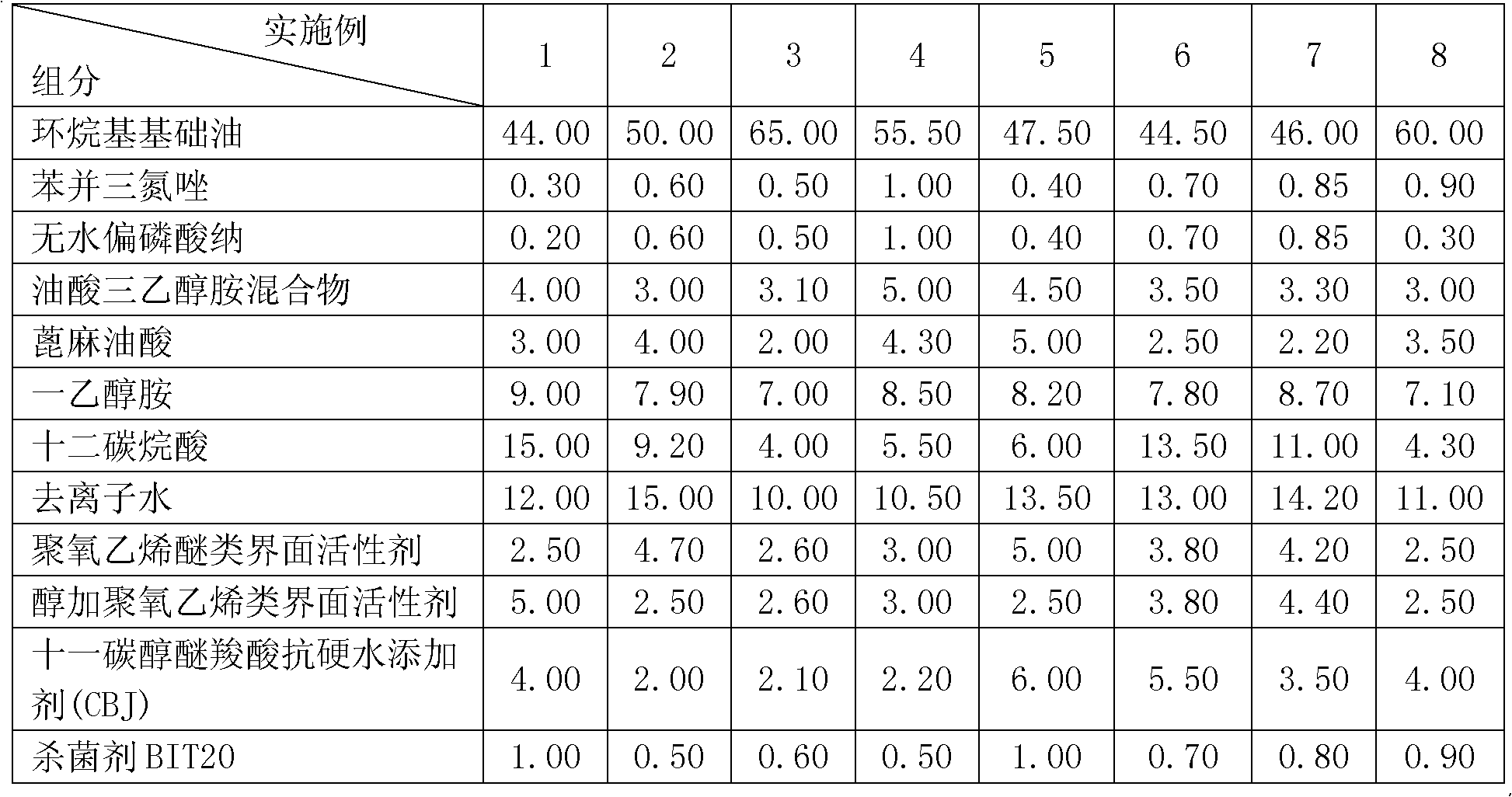

[0037] Embodiment: The formula of each embodiment of the environment-friendly emulsified cutting fluid of the present invention is shown in Table 1 below:

[0038] Table 1 (unit: % by weight)

[0039]

[0040] In Table 1 above:

[0041] The naphthenic base oil has a viscosity of 8mm at 40°C 2 / s of naphthenic base oil;

[0042] The polyoxyethylene ether-based surfactant is a polyoxyethylene ether-based surfactant with 8 EOs; the alcohol-added polyoxyethylene-based surfactant is a polyoxyethylene ether-based surfactant with 9 EOs . Among them, EO is a term in the chemical industry, which refers to ethylene oxide.

[0043] The oleic acid-triethanolamine mixture is obtained by using oleic acid and triethanolamine as raw materials through condensation reaction, so it is a mixture mainly comprising oleic acid-triethanolamine.

[0044] In the present invention, naphthenic base oil plays the role of lubricating; benzotriazole plays the role of anti-oxidation and anti-discolor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com