Graphene oxide-containing water-based metal cutting fluid and preparation method thereof

A graphene dispersion liquid and base metal technology, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve problems such as environmental impact, and achieve the effect of reducing emissions, production costs and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

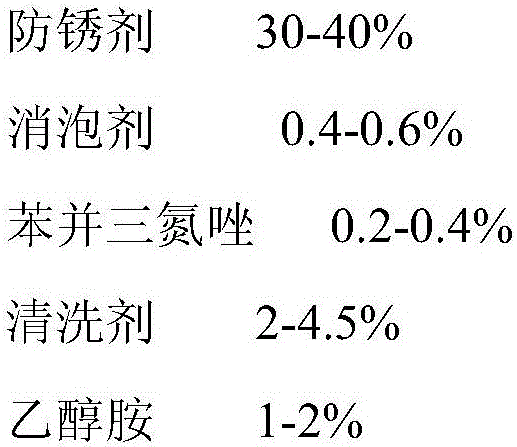

[0027] A water-based metal cutting fluid containing graphene oxide, which is calculated by weight percentage, and its raw material composition and content are as follows:

[0028] Lubricating additives: 1%;

[0029] Rust inhibitor: 35%;

[0030] Defoamer: 0.6%;

[0031] Benzotriazole: 0.4%;

[0032] Cleaning agent: 3%;

[0033] Ethanolamine: 1.5%;

[0034] The remainder is water;

[0035] Described lubricity additive is graphene oxide dispersion liquid, and its raw material composition and content are as follows by weight percentage:

[0036] Graphene oxide: 0.2%;

[0037] Polyvinylpyrrolidone: 3%;

[0038] The balance is deionized water;

[0039] Described lubricating additive, i.e. the preparation method of graphene oxide dispersion liquid, concrete operation steps are as follows:

[0040] A certain amount of prepared graphene oxide is placed in deionized water, and then ultrasonically dispersed to obtain a graphene oxide suspension, then the prepared polyvinylpyrro...

Embodiment 2

[0049] A water-based metal cutting fluid containing graphene oxide, which is calculated by weight percentage, and its raw material composition and content are as follows:

[0050] Lubricating additives: 3%;

[0051] Rust inhibitor: 40%;

[0052] Defoamer: 0.5%;

[0053] Benzotriazole: 0.3%;

[0054] Cleaning agent: 4%;

[0055] Ethanolamine: 2%;

[0056] The remainder is water;

[0057] The lubricating additive is a graphene oxide dispersion liquid, and its raw material composition and content are as follows: graphene oxide, 0.1%; polyvinylpyrrolidone, 2%; the balance is deionized water.

[0058] The preparation method of the lubricating additive graphene oxide dispersion, its specific operation steps are the same as in Example 1.

[0059] Above-mentioned graphene oxide-containing metal cutting fluid, wherein the specific preparation method of the rust inhibitor is the same as in Example 1.

[0060] The specific preparation method of the above-mentioned defoamer is the ...

Embodiment 3

[0064] A water-based metal cutting fluid containing graphene oxide, which is calculated by weight percentage, and its raw material composition and content are as follows:

[0065] Lubricating additives: 4.5%;

[0066] Rust inhibitor: 30%;

[0067] Defoamer: 0.4%;

[0068] Benzotriazole: 0.2%;

[0069] Cleaning agent: 2%;

[0070] Ethanolamine: 1%;

[0071] The remainder is water;

[0072]The lubricity additive is a graphene oxide dispersion liquid, and its raw material composition and content are as follows: graphene oxide, 0.4%; polyvinylpyrrolidone, 4%; and deionized water as the balance.

[0073] The preparation method of the lubricating additive graphene oxide dispersion, its specific operation steps are the same as in Example 1.

[0074] The above-mentioned water-based metal cutting fluid containing graphene oxide, wherein the specific preparation method of the rust inhibitor is the same as in Example 1.

[0075] The specific preparation method of the above-mention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com