Water-based phosphor copper anode cleaning agent and preparation method thereof

A cleaning agent, phosphor copper technology, applied in the field of water-based phosphor copper anode cleaner and its preparation, to achieve the effect of high cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

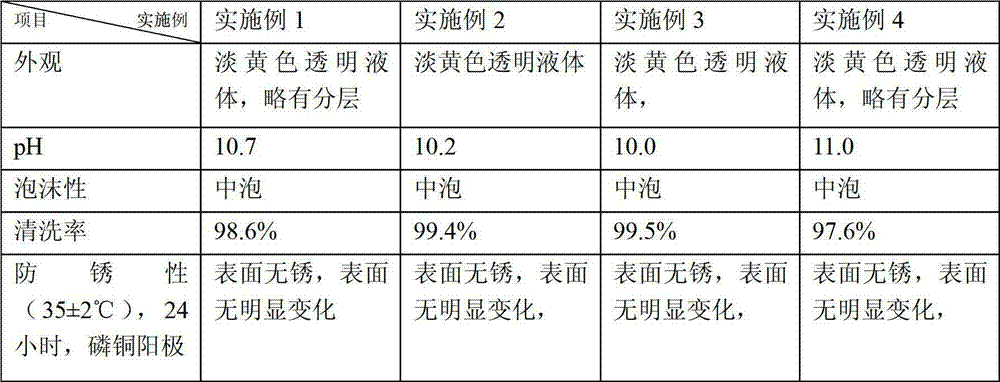

Examples

Embodiment 1

[0027] Mix 5g of sodium dodecylbenzenesulfonate, 5g of sodium secondary alkyl sulfonate, 8g of fatty alcohol polyoxyethylene (9) ether, Tween-801g, 1g of triethanolamine oleate, 2g of penetrant JFC and 4g of betaine Uniformly obtain solution A (that is, mixed surfactants, the weight of which is 26g in total); take 30g of water and dissolve 8g of sodium carbonate, 6g of sodium hydroxide, 2g of sodium citrate, 0.5g of sodium benzoate, 801g of Span-801g, and 1g of triethanolamine to obtain a solution B, add A into B and stir evenly, then add water to 100g.

Embodiment 2

[0029] Sodium dodecylbenzenesulfonate 3g, sodium secondary alkylsulfonate 7g, fatty alcohol polyoxyethylene (9) ether 4g, Tween-801.5g, oleic acid triethanolamine 2.5g, penetrant JFC 4g and betaine Mix 3.5g evenly to obtain solution A (that is, the mixed surfactant, whose weight is 25.5g in total); take 40g of water to dissolve 8g of sodium carbonate, 2g of sodium hydroxide, 0.5g of sodium edetate, 1g of sodium benzoate, and Span- 802g, 2g of triethanolamine to obtain solution B, add A to B and stir evenly, then add water to 100g.

Embodiment 3

[0031] Add 4.5g sodium dodecylbenzenesulfonate, 8g sodium secondary alkyl sulfonate, 2g fatty alcohol polyoxyethylene (9) ether, Tween-802g, 3.5g triethanolamine oleate, 5g penetrant JFC and betaine Mix 3g evenly to get solution A (that is, mixed surfactant, its weight is 28g in total); take 35g of water to dissolve 7g of sodium carbonate, 5g of sodium hydroxide, 1.5g of sodium nitrilotriacetate, 1.5g of sodium benzoate, and 801g of Span-801g , 2g of triethanolamine to obtain solution B, add A to B and stir evenly, then add water to 100g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com