Rapid wax removing agent

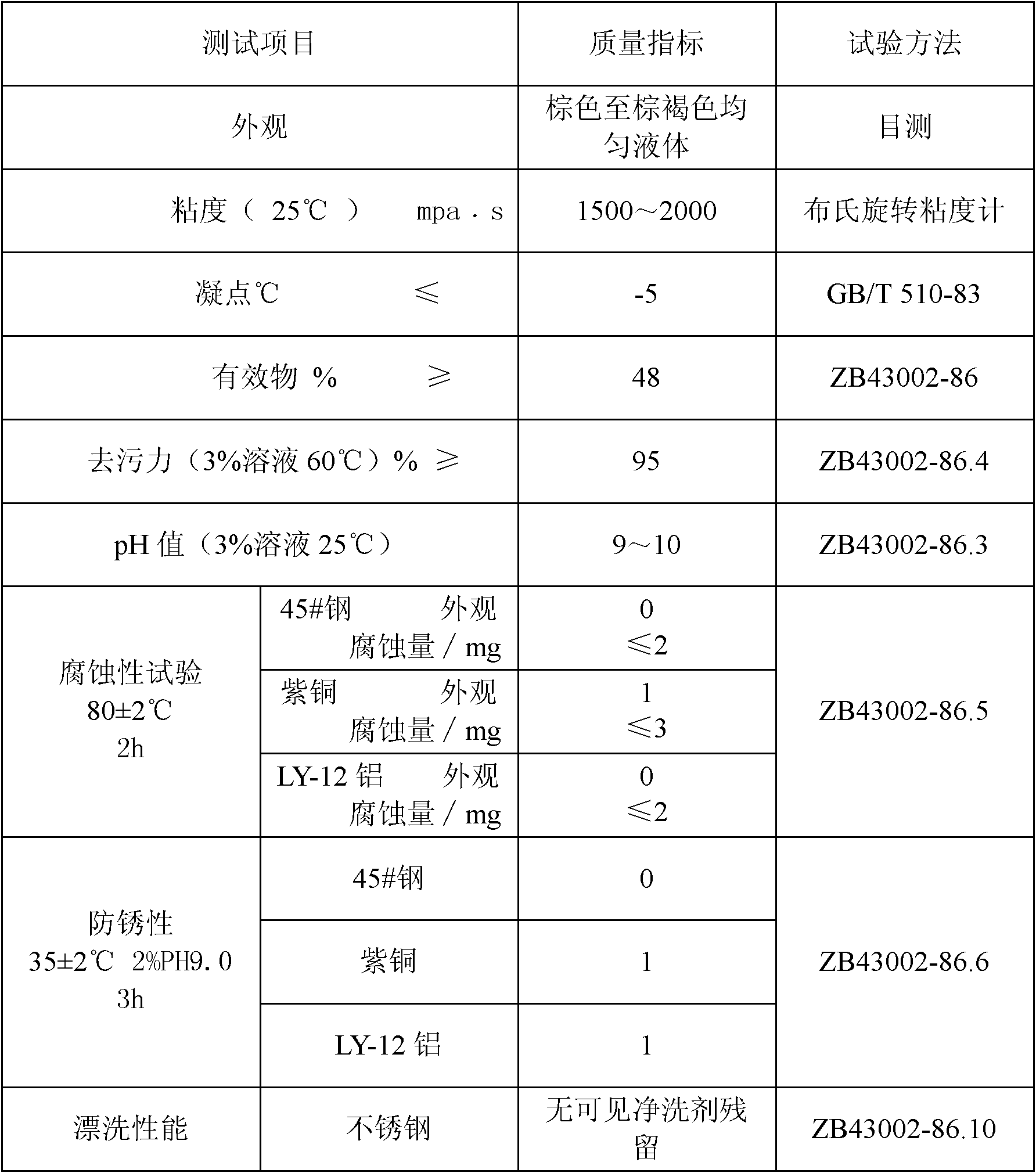

A wax remover and fast technology, applied in the field of cleaning agents, can solve the problems of flammability, high price, unevenness, etc., and achieve the effects of good asphalt removal performance, strong cleaning ability and fast dissolution speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A fast dewaxing agent, prepared in a high-quality stainless steel blending kettle, using an anchor agitator and a reducer to adjust the speed, the speed is about 50-150r / min, and the blending kettle should have a jacket for heating (cooling) and temperature control .

[0015] The weight ratio of raw and auxiliary materials prepared by it includes: oleic acid 15kg; triethanolamine 10kg; EDTA disodium salt 0.1kg; T706: 0.1kg; urea 0.5kg; 6501: 10kg; T154: 0.5kg; 4.0kg; ethylene glycol butyl ether 1.5kg; N-methylpyrrolidone 4kg; cyclohexane 1.5kg; monoethanolamine 1.5-2.0kg, add water to 100kg.

[0016] The process steps for preparing the liquid composition are as follows: react oleic acid and triethanolamine at 80-120°C to form oleic acid triethanolamine soap, and then add an appropriate amount of pure water (50-60% of the formula amount) %, about 30~35kg), lower the temperature to about 80°C, add EDTA disodium salt, T706 and urea, then add 6501 and composite dispersant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com