Detergent composition special for automatic dishwasher

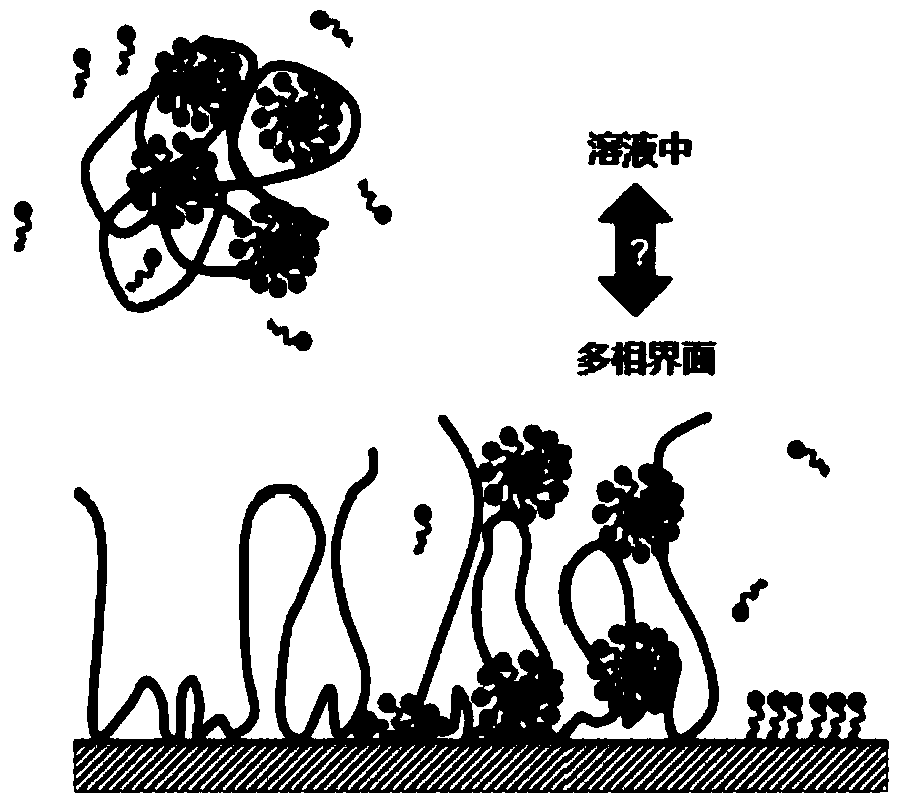

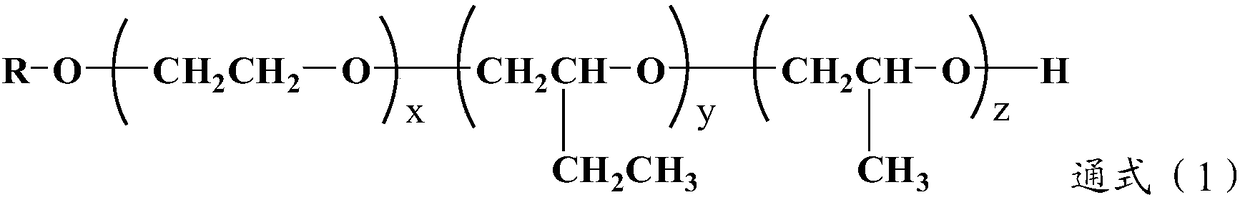

A technology for automatic dishwashers and compositions, which is applied in the direction of detergent compositions, organic detergent compositions, surface active detergent compositions, etc. It can solve the problems affecting the decontamination effect of dishwashers and improve the emulsification and dispersion effect , Improve washing efficiency and ensure the effect of water flow pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0269] The preparation of the second phase is independent of the preparation of the first phase. The second phase may also be compacted, for example from a powder or granular composition, or by extrusion or injection moulding. The second phase may also be a non-compressible phase, for example formed by forming a gel from a liquid composition with a gelling agent, or allowing post-melt solidification of the desired components. The second phase may also contain one or more fractions of different composition. The lower surface of the second phase is planar or substantially planar and ideally matches the upper surface of the first phase to ensure that they adhere to each other. For example, both surfaces may be smooth, or the upper surface of the first phase may be convex and the lower surface of the second phase may be concave, or vice versa.

[0270] But while the surfaces of the first and second phases can be of any shape, they should preferably be shaped without sharp edges ...

Embodiment 1 and comparative example 1、 comparative example 2

[0339] According to the automatic dishwasher special detergent composition A and A', B', C' formulated according to the following table 4.

[0340]

[0341]

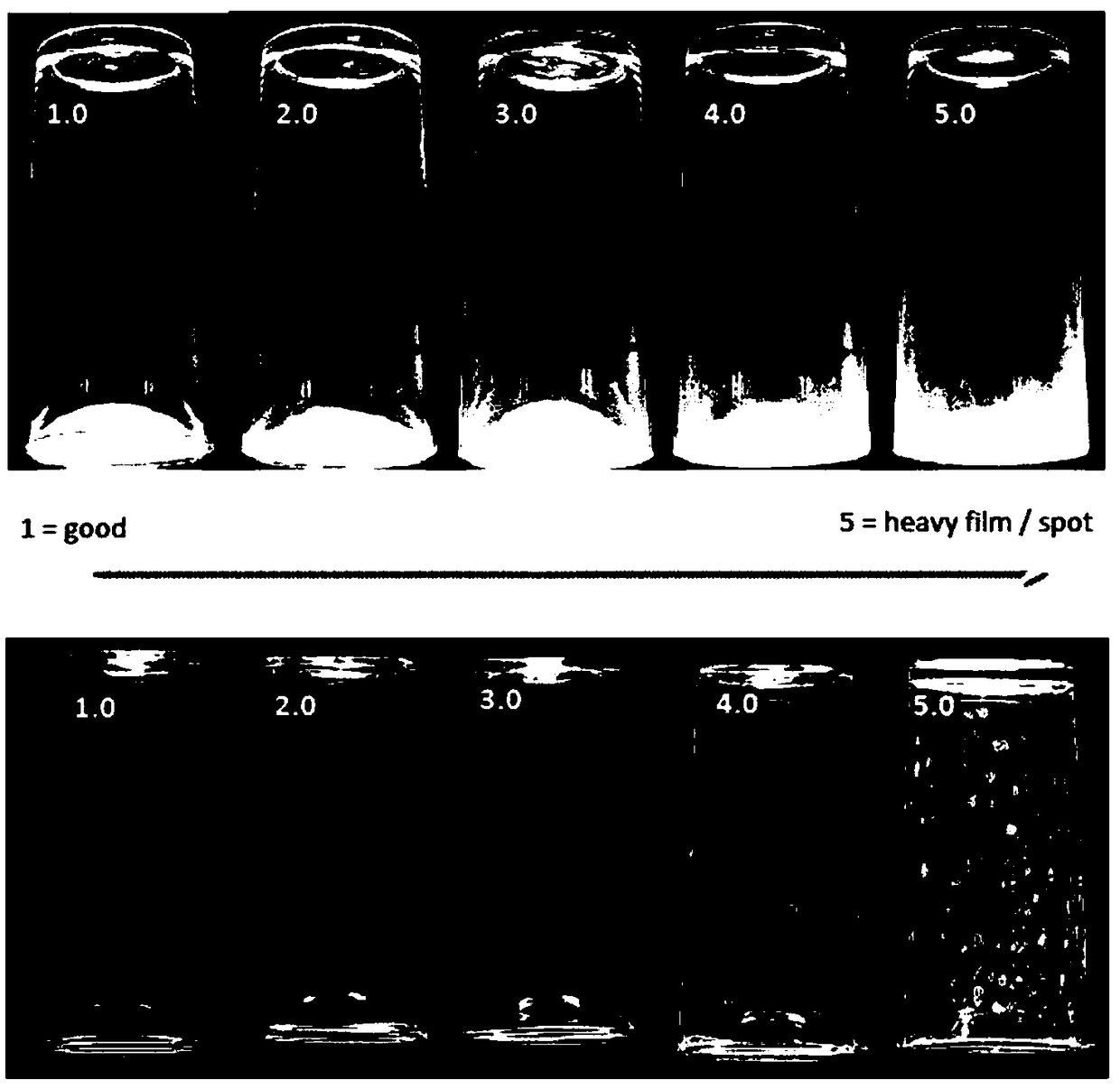

Embodiment 1

[0343] The test results of embodiment 1 and comparative example 1, comparative example 2, powdery detergent composition A and A', B', C' of comparative example 3 are shown in table 4. As can be seen from the results in Table 4, in the above-mentioned comparative examples, comparative example 1, comparative example 2 and comparative example 3 are incomplete examples of the technical solutions of the present invention, which contain polyether surfactant and Fatty alcohol alkoxylate compound, the detergency test effect of embodiment 1 and the performance of artificial dirt, oat dirt and foam reduction are all better than comparative examples 1,2,3. Its result shows that polyether surfactant and two kinds of fatty alcohol alkoxylates are compounded and used in the technical scheme provided by the embodiment of the present invention, which plays a synergistic effect and fully exerts the effect of effective components on reducing foam. Control and enhance the emulsifying and dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com