Low silicon content coolant liquid applicable to aluminum radiator of heavy-duty commercial vehicle engine

A technology for commercial vehicles and engines, which is applied to the cooling of engines, engine components, machines/engines, etc. It can solve the problem that the coolant is not suitable for heavy vehicles, etc., and achieve the effect of improving heat exchange and cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

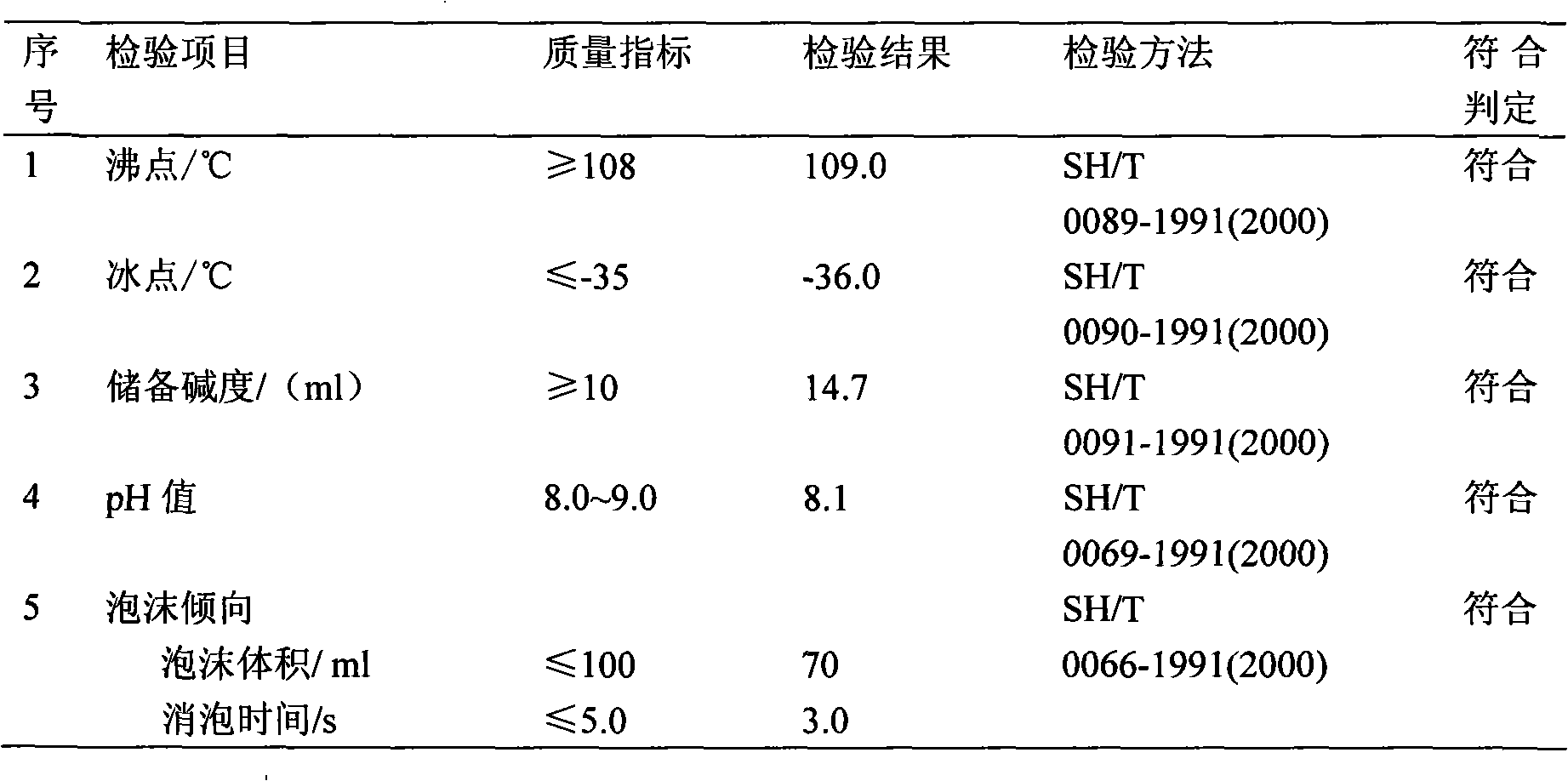

Image

Examples

Embodiment 1

[0031] Polyester grade ethylene glycol 36kg, mannitol 1.0kg, benzoic acid 0.3kg, adipic acid 0.7kg, tolyl benzotriazole (TTA) 0.1kg, p-nitrobenzoic acid 0.05kg, polyether (6100) 0.001kg, potassium phosphate 0.3kg, sodium nitrite 0.2kg, sodium nitrate 0.25kg, borax 0.5kg, sodium silicate 0.007kg, water-soluble fluorescent red 0.002kg, sodium hydroxide 0.45kg, distilled water 60.14kg.

[0032] Preparation method: (1) take by weighing 15% ethylene glycol of formula quantity and 15% distilled water of formula quantity and add the mannitol of formula quantity, benzoic acid, adipic acid, tolyl benzotriazole (TTA), p- -Nitrobenzoic acid, polyether (6100); heated to 50°C; stirred for 5 minutes until dissolved; (2) adding potassium phosphate, sodium nitrite, sodium nitrate, and borax in distilled water weighing 30% of the formula quantity , sodium silicate, heated to 50°C; stirred for 5 minutes until dissolved; (3) mixed the semi-finished raw materials of steps (1) and (2), and stirred...

Embodiment 2

[0034] Polyester grade ethylene glycol 44kg, mannitol 1.25kg, benzoic acid 0.5kg, adipic acid 0.8kg, tolyl benzotriazole (TTA) 0.15kg, p-nitrobenzoic acid 0.075kg, polyether (6100) 0.002kg, potassium phosphate 0.5kg, sodium nitrite 0.22kg, sodium nitrate 0.275kg, borax 0.75kg, sodium silicate 0.013kg, s-triazine fungicide 0.005kg, mercaptobenzothiazole sodium (MBT) 0.025kg, water soluble Fluorescent blue 0.011kg, sodium hydroxide 0.56kg, distilled water 50.864kg.

[0035] Preparation:

[0036] (1) take by weighing 17% ethylene glycol of formula quantity and 18% distilled water of formula quantity and add the mannitol of formula quantity, benzoic acid, adipic acid, tolyl benzotriazole (TTA), p-nitro Benzoic acid, polyether (6100); heated to 60°C; stirred for 7.5min until dissolved;

[0037] (2) Potassium phosphate, sodium nitrite, sodium nitrate, borax, sodium silicate, s-triazine bactericide, sodium mercaptobenzothiazole (MBT) of formula quantity are added in the distilled w...

Embodiment 3

[0042] Polyester grade ethylene glycol 52kg, mannitol 1.5kg, benzoic acid 0.7kg, adipic acid 0.9kg, tolyl benzotriazole (TTA) 0.2kg, p-nitrobenzoic acid 0.1kg, polyether (6100) 0.004kg, potassium phosphate 0.7kg, sodium nitrite 0.25kg, sodium nitrate 0.3kg, borax 1.0kg, sodium silicate 0.02kg, s-triazine fungicide 0.01kg, mercaptobenzothiazole sodium (MBT) 0.05kg, water soluble Fluorescent yellow 0.02kg, sodium hydroxide 0.68kg, distilled water 41.566kg.

[0043] Preparation:

[0044] (1) take by weighing 20% ethylene glycol of formula quantity and 20% distilled water of formula quantity and add the mannitol of formula quantity, benzoic acid, adipic acid, tolyl benzotriazole (TTA), p-nitro Benzoic acid, polyether (6100); heated to 70°C; stirred for 10 minutes until dissolved;

[0045] (2) Potassium phosphate, sodium nitrite, sodium nitrate, borax, sodium silicate, s-triazine bactericide, sodium mercaptobenzothiazole (MBT) of formula quantity are added in the distilled wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com