Heat exchange cooling device and operation method for smelting furnace

A technology of cooling device and smelting furnace, applied in furnace cooling, furnace, furnace components and other directions, can solve the problems of increasing heat conduction distance, low heat exchange cooling efficiency, short service life, etc., and achieves a high degree of automation, ingenious structure, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

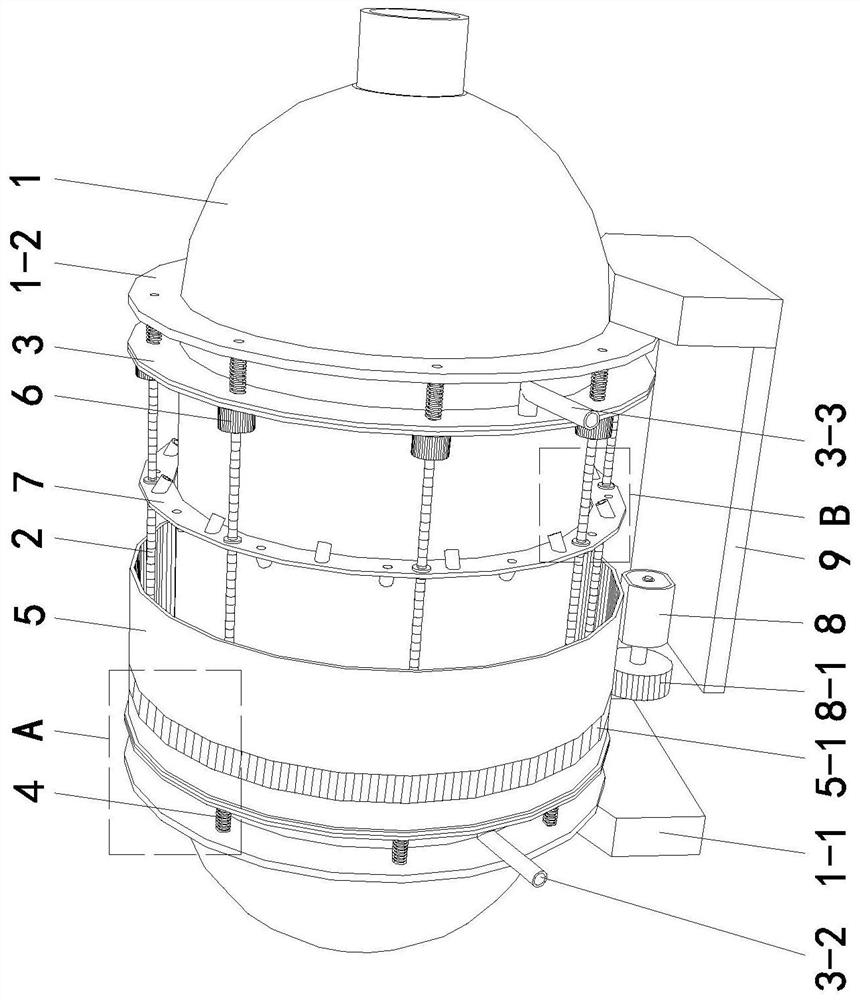

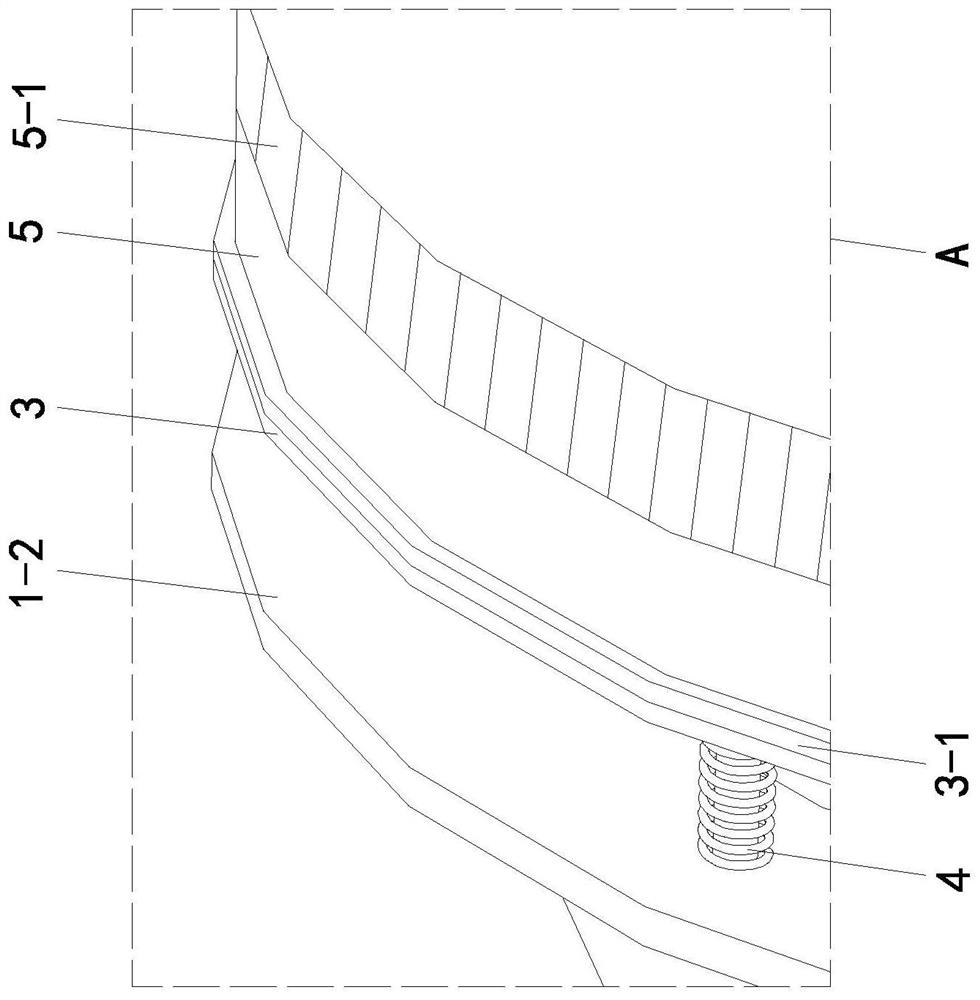

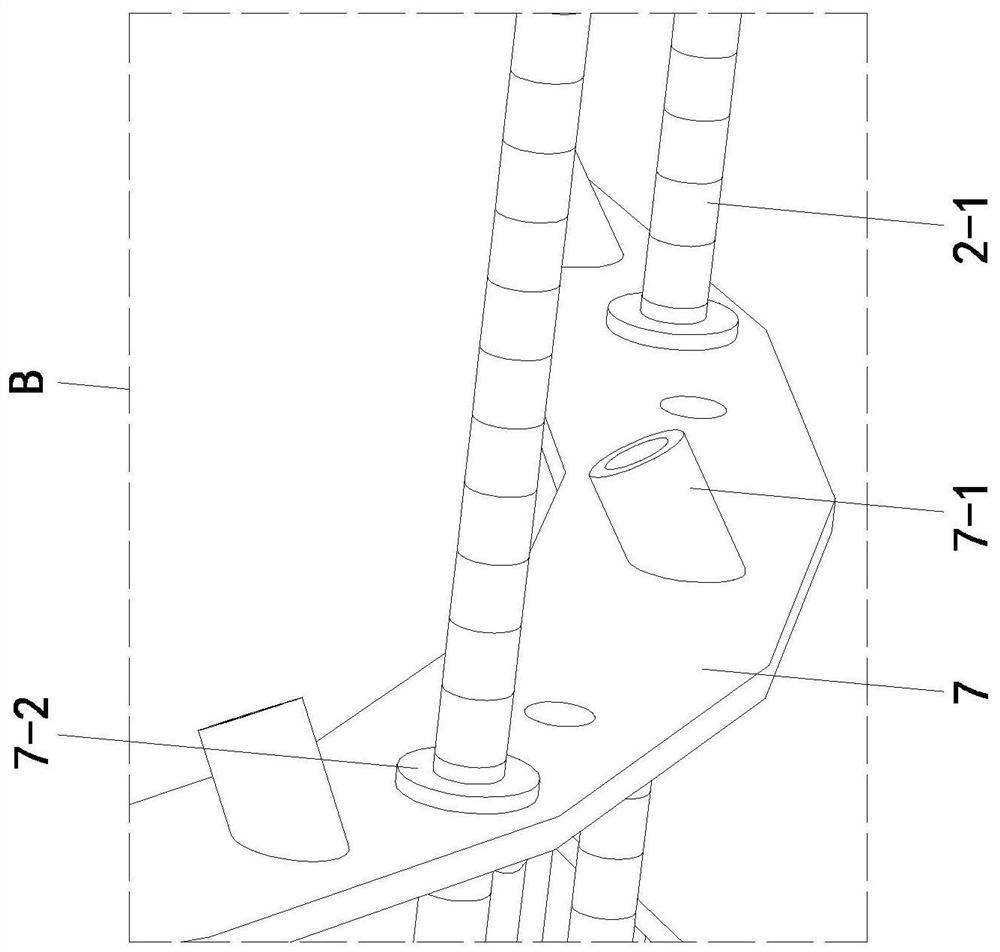

[0016] Specific implementation mode one: as Figure 1 to Figure 4 As shown, the present invention discloses a heat exchange cooling device for a smelting furnace, which includes a horizontal smelting furnace body 1. Support 1-1, the heat exchange and cooling device of the smelting furnace also includes a drum 5, an extrusion water spray ring 7, a servo motor 8, two annular sealing plates 3, a plurality of driving rotating rods 2, a plurality of compression springs 4 and A plurality of gears 6, two flanges 1-2 are coaxially fixed at both ends of the outer wall of the horizontal smelting furnace body 1, and a plurality of driving drives are installed between the two flanges 1-2 at equal angles along the circumferential direction. The rotating rod 2, the two annular sealing plates 3 and the corresponding positions of the plurality of driving rotating rods 2 are respectively provided with perforations and fixed sealing rings, and the two annular sealing plates 3 are set on the plu...

specific Embodiment approach 2

[0017] Specific implementation mode two: as figure 1 As shown, this embodiment is a further description of Embodiment 1, and the transmission ratio between the driving wheel 8-1 and the gear 6 is 1:1.

specific Embodiment approach 3

[0018] Specific implementation mode three: as figure 1 As shown, this embodiment is a further description of Embodiment 1, and the outer cover of the servo motor 8 is provided with a waterproof box.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com