Water-saving and white smoke-resisting composite closed cooling tower and control method thereof

A closed cooling tower and white smoke technology, applied in the field of cooling towers, can solve the problems of reducing work efficiency, affecting product quality, and poor white mist removal effect, so as to avoid energy waste, prevent white smoke, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

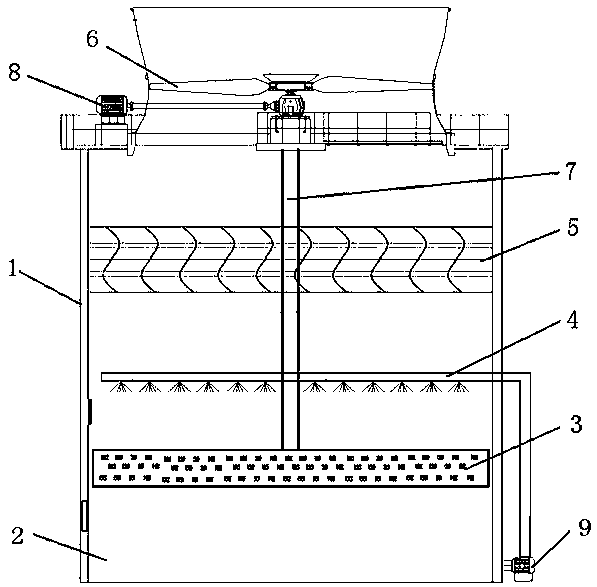

[0025] Such as figure 1 As shown, a water-saving and white-smoke-proof composite closed-type cooling tower includes a tower body 1, and the tower body 1 is sequentially provided with a water collection tank 2, a heat exchange filler 3, a spray device 4, and a water eliminator 5 from bottom to top. , the heat exchange filler 3 is arranged on the filler frame, the side wall of the filler frame is a mesh structure, which is convenient for the discharge of water vapor, the top of the tower body 1 is provided with an air outlet, the air outlet is provided with an exhaust impeller 6, and the exhaust impeller 6 is arranged on the rotating shaft 7, the rotating shaft 7 is connected to the motor reducer 8 through transmission, and one end of the rotating shaft 7 passes through the spray device 4 and the water receiver 5 and is connected to the packing frame, so that the packing can be driven to rotate with the rotating shaft 7, and the heat exchange packing 3 can be put on the The mois...

Embodiment 2

[0031] A control method for a water-saving and white-smoke-proof composite closed cooling tower, comprising the following steps:

[0032] Step S1, obtaining the humidity value collected by the humidity sensor; the controller is used to obtain the humidity value collected by the humidity sensor installed in the tower body 1. In this example, the controller can use a single-chip microcomputer.

[0033] Step S2, judging whether the humidity value matches the preset humidity threshold; after the controller acquires the humidity value, compares the humidity value with the preset humidity threshold stored inside.

[0034] Step S3, if yes, generate a control signal; the controller outputs a corresponding control signal according to the comparison result.

[0035] Step S4. Control the speed of the motor reducer according to the control signal; and the controller adjusts the speed of the motor reducer according to the corresponding control signal, so as to achieve the purpose of intell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com