Novel civil oiling agent composition for FDY polyester filament yarn and preparation method for novel civil oiling agent composition for FDY polyester filament yarn

A polyester filament and composition technology, which is applied to the new type of civil FDY polyester filament oil composition and its preparation field, can solve the problem that the antistatic property cannot meet the requirements, the smoothness effect is not good, and the content of the smoothing agent is low, etc. problem, to achieve the effect of excellent antistatic property, excellent spinnability and less residue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

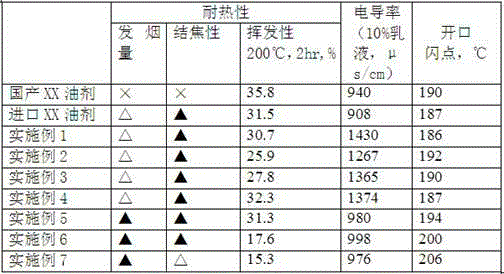

Examples

Embodiment 1

[0049] 5 kg of lauryl alcohol monoisopropanolamide polyoxyethylene ether (3EO) phosphate potassium salt, 5 kg of sodium dodecyl sulfonate, 2 kg of isomeric tridecyl alcohol polyoxyethylene ether (8EO), 3 kg Diethanolamide cocoate (1:2), 30kg 26# white oil, 20kg C12-C14 fatty alcohol oleate, 15kg dioctyl adipate, 12kg PEG400 laurate diester, 6kg C12 —C14 alkyl alcohol polyoxyethylene ether (3EO), 0.5 kg of vegetable oleic acid, 0.5 kg of chemical fiber oil bactericidal preservative, 0.5 kg of high-efficiency oil antioxidant, 0.5 kg of dodecyl alcohol, mixed evenly, heated and stirred FDY polyester filament oil composition.

Embodiment 2

[0051] 5 kg of lauryl alcohol monoisopropanolamide polyoxyethylene ether (5EO) phosphate potassium salt, 5 kg of iso-C8 alkyl phosphate polyoxyethylene ether (4EO) potassium salt, 5 kg of coconut acid diethanolamide (1 : 2), 3 kg of castor oil polyoxyethylene ether (20EO), 25 kg of 26# white oil, 25 kg of isomeric C13 oleate, 12 kg of dioctyl adipate, 10 kg of PEG400 diester laurate, 8 kg C 12 -C 14 Alkyl alcohol polyoxyethylene ether (3EO), 0.5 kg of vegetable oleic acid, 0.5 kg of chemical fiber oil bactericidal preservative, 0.5 kg of high-efficiency oil antioxidant, 0.5 kg of dodecyl alcohol, mixed evenly, heated and stirred FDY polyester Filament oil composition.

Embodiment 3

[0053] 5 kg of lauryl alcohol monoisopropanolamide polyoxyethylene (4EO) polyoxypropylene (2PO) ether phosphate potassium salt, 5 kg of iso-C8 alkyl phosphate polyoxyethylene ether (4EO) potassium salt, 3 kg of castor oil Polyoxyethylene ether (20EO), 5 kg palmitoleic acid monoisopropanolamide, 25 kg 32# white oil, 8 kg salad oil, 28 kg octyl stearate, 8 kg PEG800 oleic acid diester, 5 kg oleyl alcohol Polyoxyethylene ether (10EO), 6 kg C 12 -C 14 Alkyl alcohol polyoxyethylene ether (3EO), 0.8 kg of vegetable oleic acid, 0.5 kg of chemical fiber oil bactericidal preservative, 0.5 kg of high-efficiency oil antioxidant, 0.2 kg of dodecyl alcohol, mixed evenly, heated and stirred FDY polyester Filament oil composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com