Hole channel amplification method of porous ceramic microballoon sphere

A technology of porous ceramics and microspheres, which is applied in the field of pore expansion of porous ceramic microspheres, which can solve the problems of large limitations of amplified channels, and achieve the effects of improving mass transfer efficiency, less environmental pollution, and simple preparation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

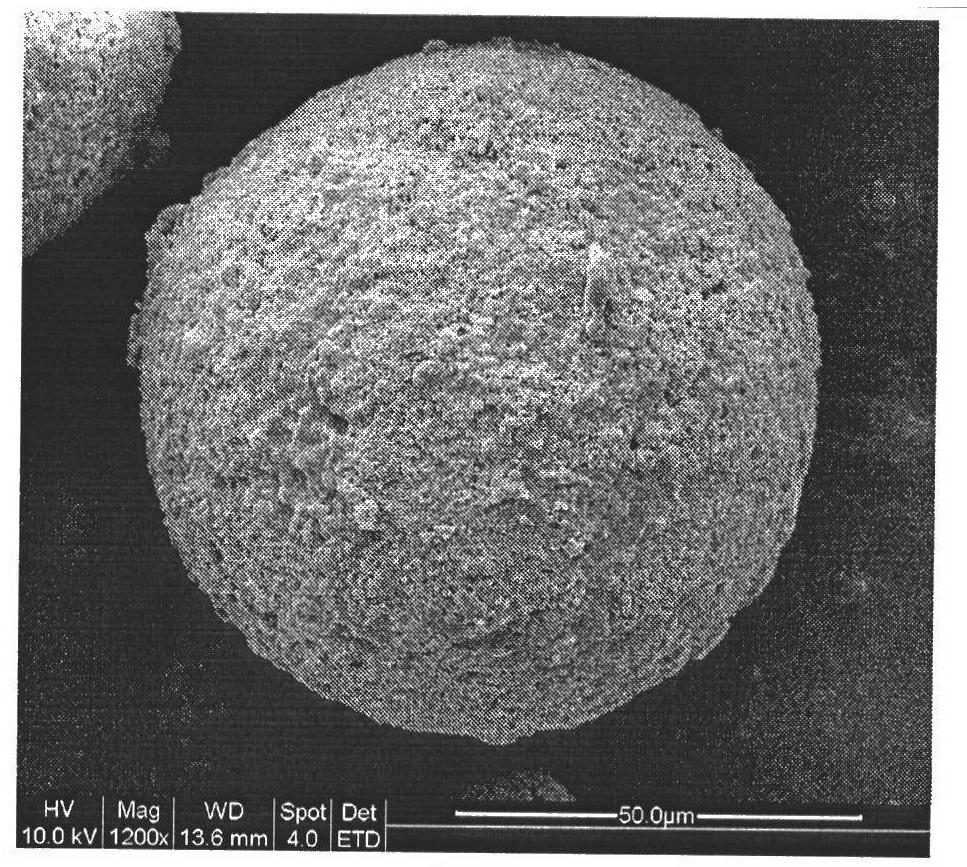

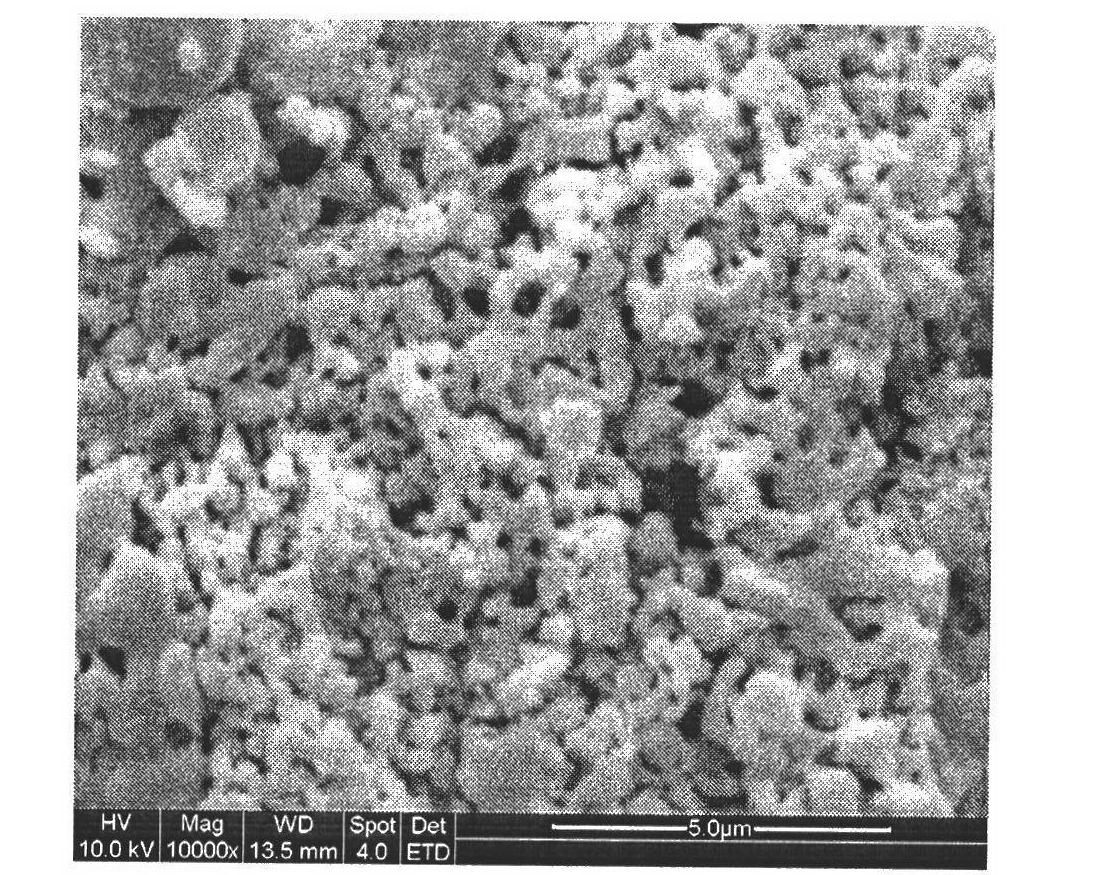

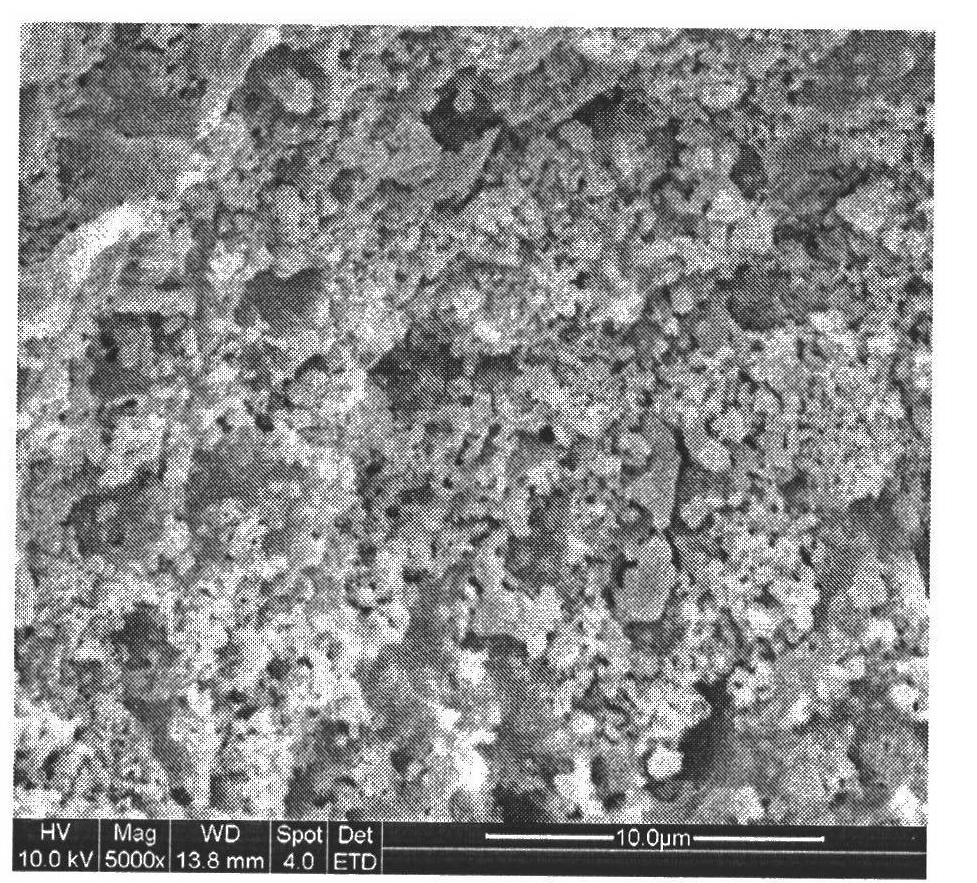

Embodiment 1

[0020] Mix 30g of nano-zirconia, 2g of citric acid, 30mL of water, 5g of nano-carbon powder and 20mL of 5% sodium alginate solution until it becomes a gel. Transfer the above ceramic slurry to a 500mL three-neck flask, add 200mL pump oil, 10mL Span 80, stir at 700r / min for 30min, add 10mL saturated calcium chloride dropwise, and continue stirring for 10min. After the reaction, the microspheres were collected by filtration, cleaned with alcohol and deionized water, dried in an oven at 50°C, heated to 1450°C in a muffle furnace, kept for 20 minutes, and cooled naturally to obtain porous ceramic microspheres. The obtained porous ceramic microspheres have an average pore size of The maximum aperture is The porosity is 60%, and the specific surface area is 22m 2 / cm 3 , with an average particle size of 120 μm.

Embodiment 2

[0022] Mix 28g of nano-titanium dioxide, 1g of citric acid, 30mL of water, 5g of polyethylene glycol and 20mL of 5% sodium alginate solution until gelled. Transfer the above ceramic slurry to a 500mL three-neck flask, add 200mL pump oil, 10mL Span 80, stir at 600r / min for 30min, add 10mL saturated calcium chloride dropwise, and continue stirring for 10min. After the reaction, the microspheres were collected by filtration, cleaned with alcohol and deionized water, dried in an oven at 50°C, heated to 1300°C in a muffle furnace, kept for 20 minutes, and cooled naturally to obtain porous ceramic microspheres. The obtained porous ceramic microspheres have an average pore size of The maximum aperture is The porosity is 62%, and the specific surface area is 22.6m 2 / cm 3 , with an average particle size of 98 μm.

Embodiment 3

[0024] Mix 12g of nano-titanium dioxide, 2g of citric acid, 30mL of water, 4g of polyvinyl alcohol and 20mL of 5% sodium alginate solution until gelled. Transfer the above ceramic slurry to a 500mL three-necked flask, add 200mL pump oil, 10mL Span 80, stir at 800r / min for 40min, add 10mL saturated calcium chloride dropwise, and continue stirring for 10min. After the reaction, the microspheres were collected by filtration, cleaned with alcohol and deionized water, dried in an oven at 60°C, heated to 1000°C in a muffle furnace, kept for 20 minutes, and cooled naturally to obtain porous ceramic microspheres. The obtained porous ceramic microspheres have an average pore size of The maximum aperture is The porosity is 58%, and the specific surface area is 20.7m 2 / cm 3 , with an average particle size of 118 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com