Oil agent for chopped polyester fiber

A technology of polyester staple fiber and oil agent, which is applied in the directions of fiber treatment, fiber type, textile and paper making, etc., can solve the problems of affecting the strength and dispersibility of oil film, increase the viscosity of oil agent emulsion, etc., and achieve a large amount of oil agent. , the effect of large oil film strength, excellent emulsion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The polyester staple fiber oil agent according to the present embodiment is mixed by the following components: 30% isooctyl stearate; 10% sodium diethyl alcohol sulfosuccinate; 4% sorbitan oleate; Dialkyl polyoxyethylene ether (5) 20%; lauryl polyoxyethylene ether (10) 10%; POE alkyl phosphate potassium salt 10%; softener A 4%; fatty alcohol ethylene oxide 4% ; Tween-80 8%.

Embodiment 2

[0051] The polyester staple fiber oil agent according to the present embodiment is mixed by the following components: 28% isooctyl stearate; 12% sodium diethyl alcohol sulfosuccinate; 4% sorbitan oleate; Dialkyl polyoxyethylene ether (5) 22%; lauryl polyoxyethylene ether (10) 12%; POE alkyl phosphate potassium salt 10%; softener A 4%; fatty alcohol ethylene oxide 4% ; Tween-80 4%.

Embodiment 3

[0053] According to the polyester staple fiber oil of the present embodiment, the following components are mixed: isooctyl stearate 32%; sodium diethyl alcohol sulfosuccinate 12%; sorbitan oleate 4%; Dialkyl polyoxyethylene ether (5) 22%; lauryl polyoxyethylene ether (10) 12%; POE alkyl phosphate potassium salt 8%; softener A 4%; fatty alcohol ethylene oxide 4% ; Tween-80 2%.

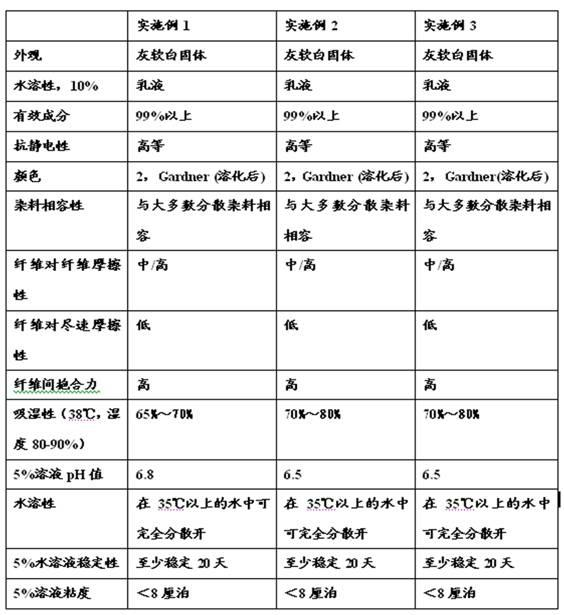

[0054] See Table 1, which shows the performance parameters of the staple fiber polyester oil agents of Examples 1-3.

[0055] Table 1

[0056]

[0057] In summary, the polyester staple fiber oil agent of the present invention can improve the softness and lubricity of the staple fibers, and make the fibers easy to loosen, so as to facilitate the process of unpacking, blending, and carding; the formula contains strong anionic antistatic It can effectively prevent static electricity during carding and stretching, and is beneficial to stretching, roving and spinning processes. Adopting the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com