Method for extracting vanadium and chromium from vanadium-containing steel slag by high-alkalinity potassium hydroxide

A potassium hydroxide and high alkalinity technology, applied in the field of metallurgy, can solve the problems of low effective calcium oxide content, highly toxic chromium-containing slag, difficult treatment, etc. The effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

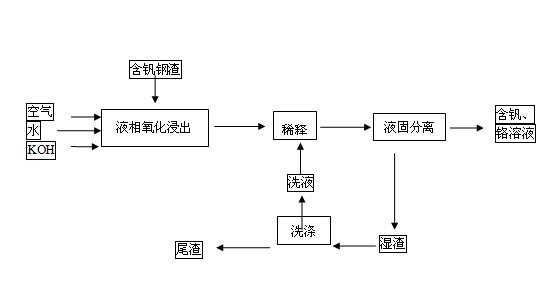

Image

Examples

Embodiment 1

[0016] A method for extracting vanadium and chromium from vanadium-containing steel slag with a high-alkalinity potassium hydroxide medium: Weigh 200g of solid analytical pure KOH into the reaction kettle, add 67mL of deionized water to an initial concentration of 75%, turn on the stirring, and heat up To 200°C, weigh 50g of vanadium-containing steel slag and place it in the reactor, and feed air into the reactor at 2L / min for a reaction time of 6h. At the end of the reaction, add 400 mL of water to the reaction kettle for dilution, and filter with suction. The alkalinity of the liquid phase is 343.6 g / L, and the residue is washed three times. Chemical analysis and instrumental analysis were used to analyze the content of slag phase and liquid phase. The total amount of vanadium in tailings is 0.122wt% (calculated as vanadium pentoxide), and the total amount of chromium in tailings is 0.103wt% (calculated as chromium trioxide). The resulting vanadium leaching rate was 96.5%, ...

Embodiment 2

[0018] A method for extracting vanadium and chromium from vanadium and chromium-containing steel slag with high alkalinity potassium hydroxide medium: Weigh 200g of solid industrial pure KOH into the reaction kettle, add 50mL of deionized water to the initial concentration of 80%, turn on the stirring, and heat The temperature was raised to 220° C., 50 g of vanadium-containing steel slag was weighed into the reactor, and air was introduced into the reactor at 2 L / min for a reaction time of 4 hours. At the end of the reaction, 600 mL of water was added to the reaction kettle to dilute, and filtered by suction, the alkalinity of the liquid phase was 230.2 g / L, and the residue was washed three times. Chemical analysis and instrumental analysis are used to analyze the contents of liquid phase and slag phase. The total amount of vanadium in the tailings is 0.101wt% (calculated as vanadium pentoxide), and the total amount of chromium in the tailings is 0.0743 wt% (calculated as chro...

Embodiment 3

[0020] A method for extracting vanadium and chromium from vanadium-containing steel slag with a high-alkalinity potassium hydroxide medium: Weigh 169g of solid analytical pure KOH and 31g of KNO3 in a reaction kettle, add 108mL of deionized water to an initial alkali concentration of 55%, KNO3 The initial concentration is 10%, turn on the stirring, heat up to 180°C, weigh 50g of vanadium-containing steel slag into the reaction kettle, and feed air into the reaction kettle at 2L / min, and the reaction time is 5h. At the end of the reaction, 500 mL of water was added to the reaction kettle for dilution, and suction filtration was performed. The alkalinity of the liquid phase was 236.3 g / L, and the residue was washed three times. Chemical analysis and instrumental analysis are used to analyze the contents of liquid phase and slag phase. The total amount of vanadium in the tailings is 0.136wt% (calculated as vanadium pentoxide), and the total amount of chromium in the tailings is 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com