Methionine separation and purification method

A technology for separation and purification of methionine, applied in chemical instruments and methods, organic chemistry, preparation of organic compounds, etc., can solve the problems of low methionine purity and poor treatment method of secondary methionine products, and achieves high single recovery rate, The effect of maximizing resource utilization and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

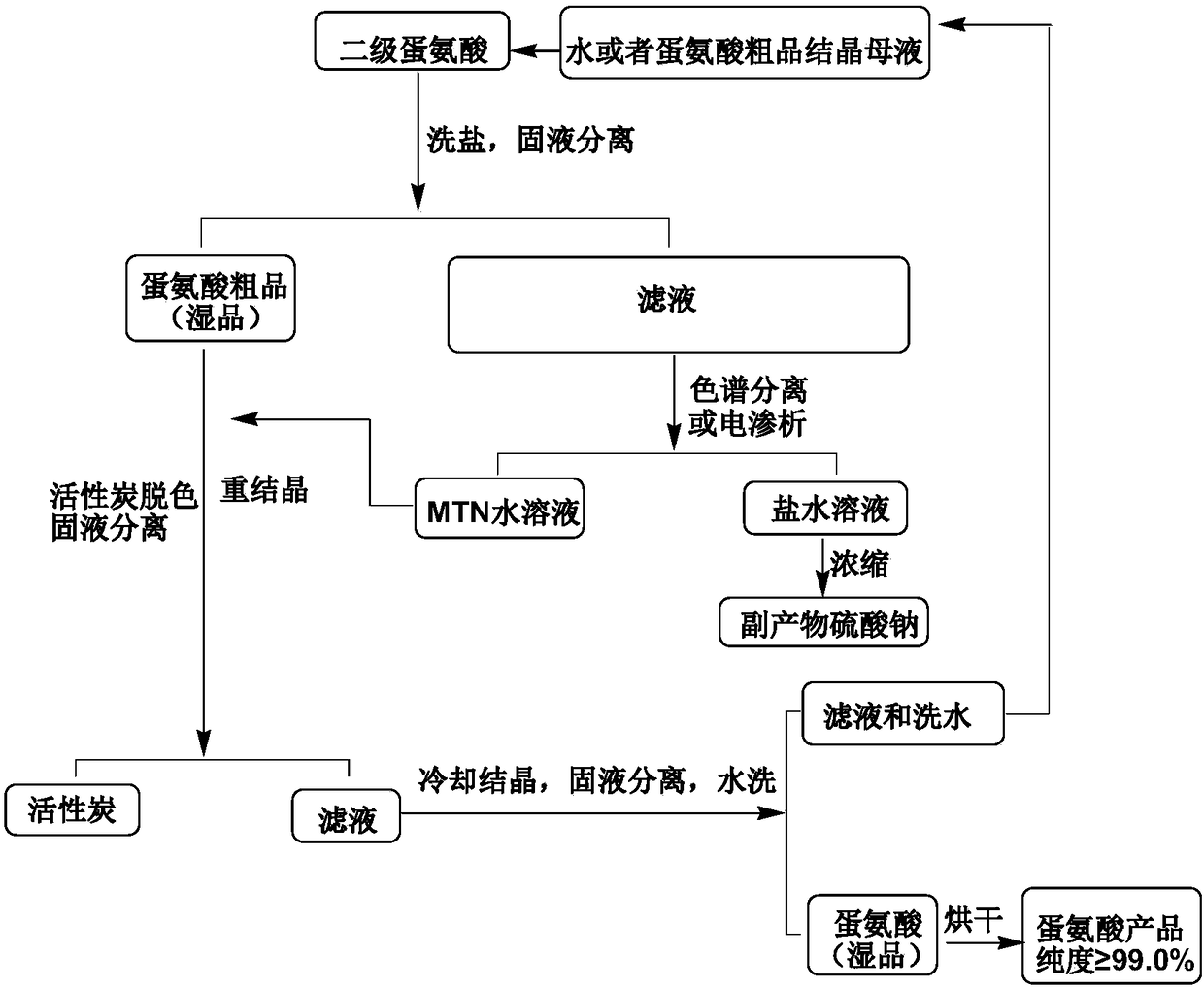

[0041] A method for separating and purifying methionine, comprising the steps of:

[0042] 1) Take 500g secondary methionine (by weight, methionine content is 35%, sodium sulfate content is 44%, moisture content is 15%, formate content is 5%, also contains a small amount of methionine dimer and unknown impurity) , added to 500ml of water, heated and kept at 35-40°C, then started to stir for 1 hour, and then carried out suction filtration to obtain crude methionine and 650ml of filtrate respectively. Adjust the pH of the filtrate to about 5.5, and the filtrate was desalted by continuous chromatography. The separation temperature is 40°C, and deionized water is used as the mobile phase to obtain 950ml of extract (methionine aqueous solution) and 1200ml of raffinate (salt solution), wherein the extract is recycled to step 2) as water for recrystallization of crude methionine, and the raffinate After concentration, cooling and crystallization in sodium sulfate.

[0043] 2) Add th...

Embodiment 2

[0046] A method for separating and purifying methionine, comprising the steps of:

[0047]1) Take 500g secondary methionine (by weight, methionine content is 35%, sodium sulfate content is 44%, moisture content is 15%, formate content is 5%, also contains a small amount of methionine dimer and unknown impurities) , added to 500ml of water, heated and kept at 35-40°C, then turned on and stirred for 1 hour, and then subjected to suction filtration to obtain crude methionine and 650ml of filtrate respectively, and the pH of the filtrate was adjusted to about 5.5, and the filtrate was desalted by homogeneous membrane electrodialysis Treatment, the desalination temperature is 35°C, 610ml of methionine aqueous solution and 650ml of saline solution are obtained respectively, wherein the methionine aqueous solution is recycled to step 2) as water for recrystallization of crude methionine, and the saline solution is concentrated, cooled and crystallized to obtain sodium sulfate.

[004...

Embodiment 3

[0051] A method for separating and purifying methionine, comprising the steps of:

[0052] 1) Take 500g secondary methionine (by weight, methionine content is 35%, sodium sulfate content is 44%, moisture content is 15%, formate content is 5%, also contains a small amount of methionine dimer and unknown impurities) , added to 500ml of water, heated and kept at 35-40°C, then turned on and stirred for 1 hour, and then suction filtered to obtain crude methionine and 650mL of filtrate, and the pH of the filtrate was adjusted to about 5.5, and the filtrate was desalted by continuous chromatography and separated by chromatography The temperature is 40°C, and deionized water is used as the mobile phase to obtain 950ml of extract (methionine aqueous solution) and 1200ml of raffinate (saline solution), wherein the extract is recycled to step 2) as water for recrystallization of crude methionine, and the raffinate is passed through Concentrate, cool and crystallize to obtain sodium sulfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com