Fine-denier or superfine-denier polyvinyl alcohol fiber and preparation method thereof

A technology of polyvinyl alcohol fiber and polyvinyl alcohol, which is applied in the direction of fiber chemical characteristics, wet spinning method, stretch spinning method, etc., which can solve the problems of lower production efficiency, low viscosity of spinning dope, and decreased spinnability of spinning dope, etc. problems, to achieve the effects of high production efficiency, stable and continuous spinning process, and obvious thickening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

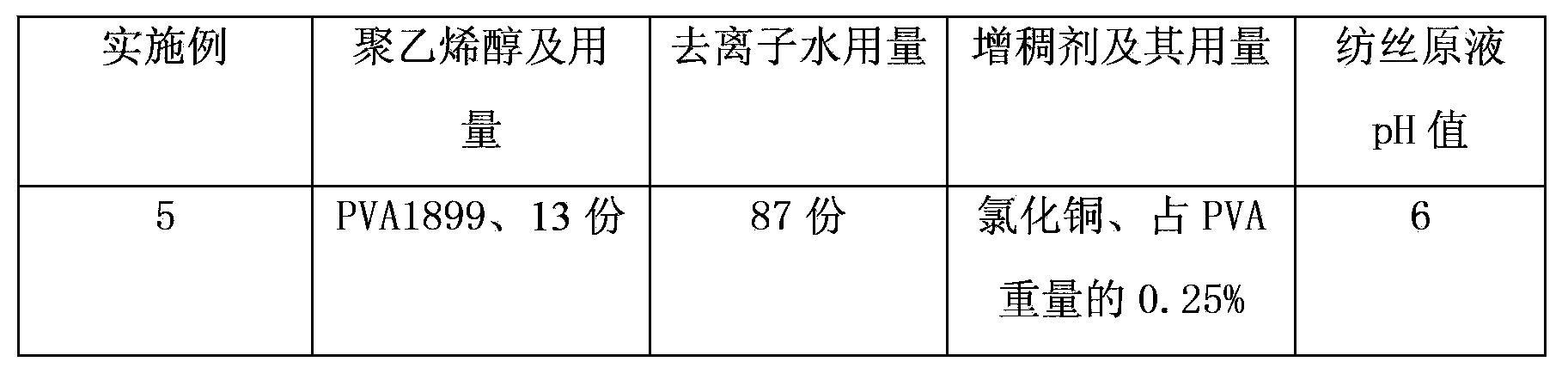

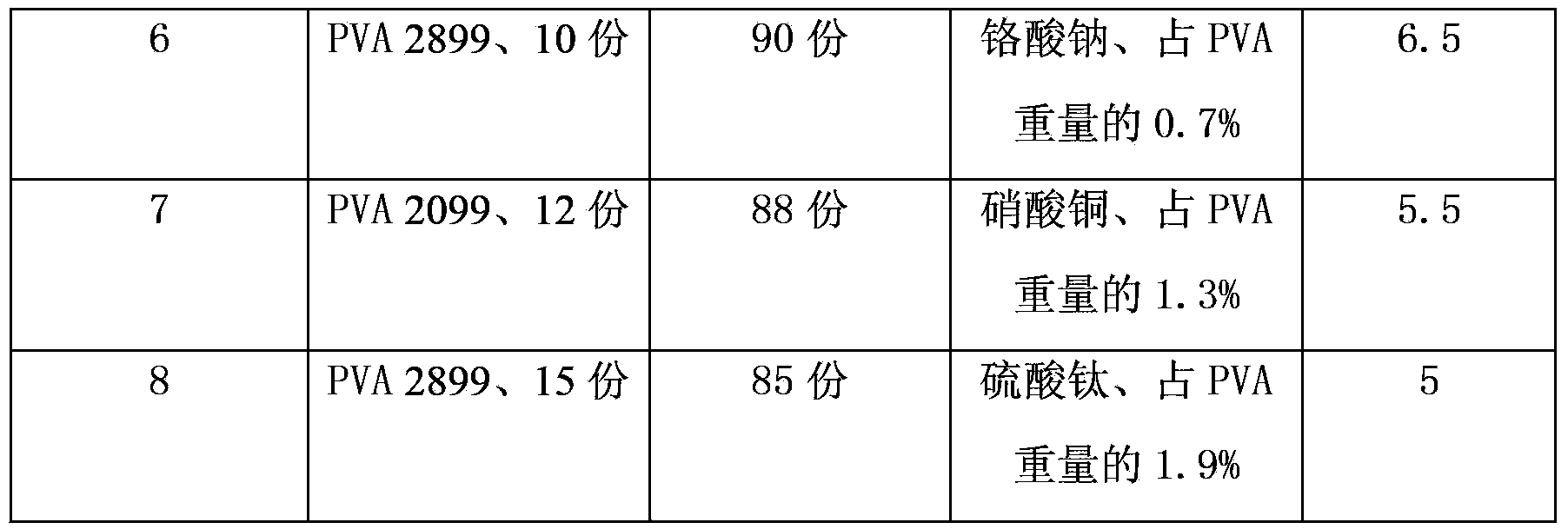

Examples

Embodiment 1

[0027]Dissolve 10kg of polyvinyl alcohol with a polymerization degree of 2600 and alcoholysis degree ≥ 99% and 90kg of deionized water at a temperature of 98°C for 3 hours to obtain a spinning stock solution, add 0.05kg of boric acid to the stock solution, and adjust the pH of the stock solution with acetic acid is 4.5. The spinning dope is filtered, defoamed, and metered by a metering pump, and then sprayed into the coagulation bath through a spinneret with a specification of 0.04mm. The coagulation bath is a mixed aqueous solution of sodium sulfate and sodium hydroxide with a density of 1.28g / mL, a sodium hydroxide concentration of 32g / L, and a temperature of 44°C. The solidified filaments are neutralized in a mixed aqueous solution of sodium sulfate and sulfuric acid with a density of 1.29g / mL, a sulfuric acid concentration of 12g / L, and a temperature of 44°C. / L, in a mixed aqueous solution of sodium sulfate and sulfuric acid at a temperature of 90°C, carry out wet heat d...

Embodiment 2

[0029] Dissolve 15kg of polyvinyl alcohol with a polymerization degree of 1600 and alcoholysis degree ≥ 99% and 85kg of deionized water at a temperature of 95°C for 2 hours to obtain a spinning stock solution, add 0.015kg of borax to the stock solution, and adjust the pH of the stock solution with acetic acid is 6.5. After the spinning dope is filtered, defoamed and metered by a metering pump, it is sprayed into the coagulation bath through a spinneret with a specification of 0.08mm. The coagulation bath is a mixed aqueous solution of sodium sulfate and sodium hydroxide with a density of 1.31g / mL, a sodium hydroxide concentration of 30g / L, and a temperature of 45°C. The solidified filaments are neutralized in a mixed aqueous solution of sodium sulfate and sulfuric acid with a density of 1.30g / mL, a sulfuric acid concentration of 10g / L, and a temperature of 45°C. / L, in a mixed aqueous solution of sodium sulfate and sulfuric acid at a temperature of 75°C, carry out wet heat dr...

Embodiment 3

[0031] Dissolve 14kg of polyvinyl alcohol with a degree of polymerization of 1700 and a degree of alcoholysis ≥99% and 86kg of deionized water at a temperature of 96°C for 3 hours to obtain a spinning stock solution, add 0.28kg of copper sulfate to the stock solution, and adjust the pH of the stock solution with acetic acid The value is 6. The spinning dope is filtered, defoamed, and metered by a metering pump, and then sprayed into the coagulation bath through a spinneret with a specification of 0.06mm. The coagulation bath is a mixed aqueous solution of sodium sulfate and sodium hydroxide with a density of 1.31 g / mL, a sodium hydroxide concentration of 28 g / L, and a temperature of 45°C. The solidified filaments are neutralized in a mixed aqueous solution of sodium sulfate and sulfuric acid with a density of 1.30g / mL, a sulfuric acid concentration of 11g / L, and a temperature of 45°C. / L, in a mixed aqueous solution of sodium sulfate and sulfuric acid at a temperature of 80°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com