Abrasion-resistant waterproof coating for building outer wall and method for preparing the same

A technology for waterproof coatings and building exterior walls, applied in the field of coatings, can solve the problems of affecting the service life of buildings, poor wear resistance and water resistance, general adhesion, etc., and achieve the effect of improving waterproof effect, low cost and good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

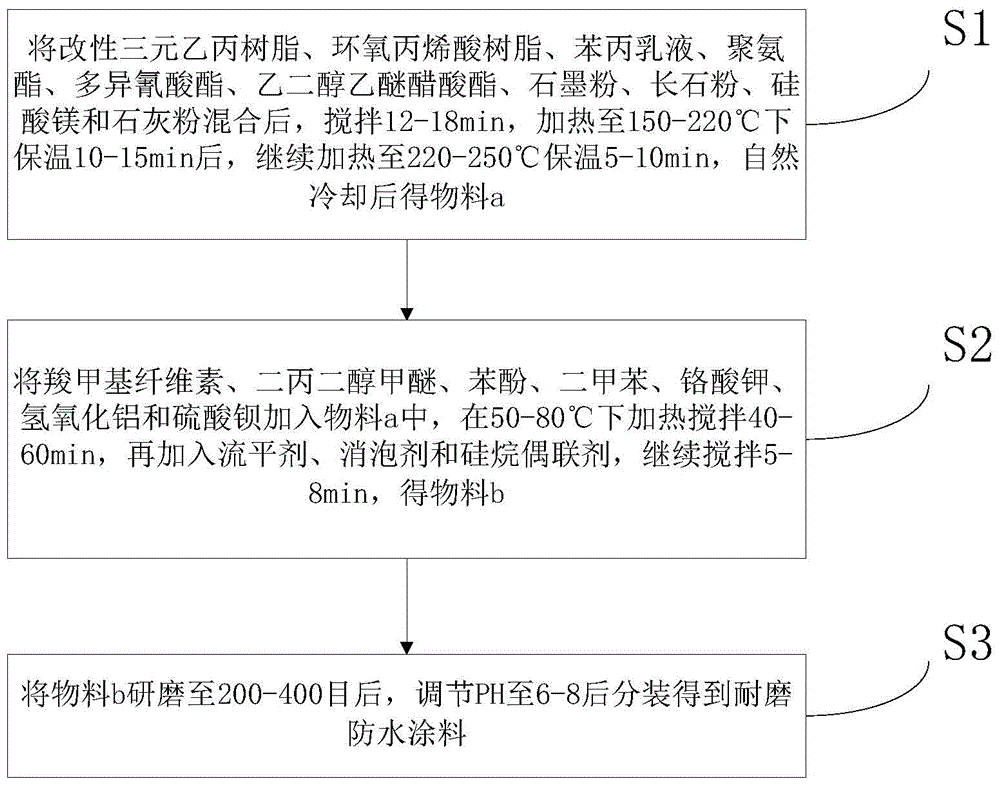

[0022] refer to figure 1 , a kind of preparation method that the present invention proposes wear-resisting waterproof paint for building exterior wall, comprises the steps:

[0023] S1. After mixing modified EPDM resin, epoxy acrylic resin, styrene-acrylic emulsion, polyurethane, polyisocyanate, ethylene glycol ether acetate, graphite powder, feldspar powder, magnesium silicate and lime powder, stir for 12- 18min, heat to 150-220°C for 10-15min, continue heating to 220-250°C for 5-10min, and cool naturally to obtain material a;

[0024] S2. Add carboxymethyl cellulose, hydroxypropyl methyl cellulose, dipropylene glycol methyl ether, phenol, xylene, potassium chromate, aluminum hydroxide and barium sulfate to material a, heat and stir at 50-80°C After 40-60 minutes, add leveling agent, defoamer and silane coupling agent, and continue stirring for 5-8 minutes to obtain material b;

[0025] S3. After the material b is ground to 200-400 mesh, the pH is adjusted to 6-8, and then ...

Embodiment 1

[0027] A kind of wear-resisting waterproof coating for building exterior wall, its raw material comprises by weight: 70 parts of modified EPDM resins, 45 parts of epoxy acrylic resins, 30 parts of styrene-acrylic emulsions, 20 parts of polyurethanes, 10 parts of polyisocyanates, 5 parts of ethylene glycol ethyl ether acetate, 5.5 parts of graphite powder, 4 parts of feldspar powder, 3 parts of magnesium silicate, 4 parts of lime powder, 4 parts of carboxymethyl cellulose, 3.5 parts of hydroxypropyl methyl cellulose, dipropylene glycol 5 parts of methyl ether, 5 parts of phenol, 5 parts of xylene, 4 parts of potassium chromate, 2 parts of aluminum hydroxide, 3 parts of barium sulfate, 2 parts of leveling agent, 4 parts of defoamer, 3 parts of silane coupling agent.

[0028]Among them, the leveling agent is a combination of polydimethylsiloxane, polyether polyester modified organosiloxane, alkyl modified organosiloxane and melamine formaldehyde resin; the defoamer is emulsified s...

Embodiment 2

[0034] A kind of wear-resisting waterproof coating for building exterior wall, its raw material comprises by weight: 60 parts of modified EPDM resins, 60 parts of epoxy acrylic resins, 20 parts of styrene-acrylic emulsions, 30 parts of polyurethanes, 5 parts of polyisocyanates, 8 parts of ethylene glycol ether acetate, 3 parts of graphite powder, 6 parts of feldspar powder, 1 part of magnesium silicate, 6 parts of lime powder, 3 parts of carboxymethyl cellulose, 5 parts of hydroxypropyl methyl cellulose, dipropylene glycol 3 parts of methyl ether, 8 parts of phenol, 3 parts of xylene, 6 parts of potassium chromate, 1 part of aluminum hydroxide, 4 parts of barium sulfate, 1 part of leveling agent, 6 parts of defoaming agent, and 1 part of silane coupling agent.

[0035] Among them, the leveling agent is a composition of polydimethylsiloxane, alkyl modified organosiloxane and melamine formaldehyde resin; the defoamer is emulsified silicone oil, polyoxyethylene polyoxypropylene pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com