Patents

Literature

201 results about "Ethylene glycol monoethyl ether acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

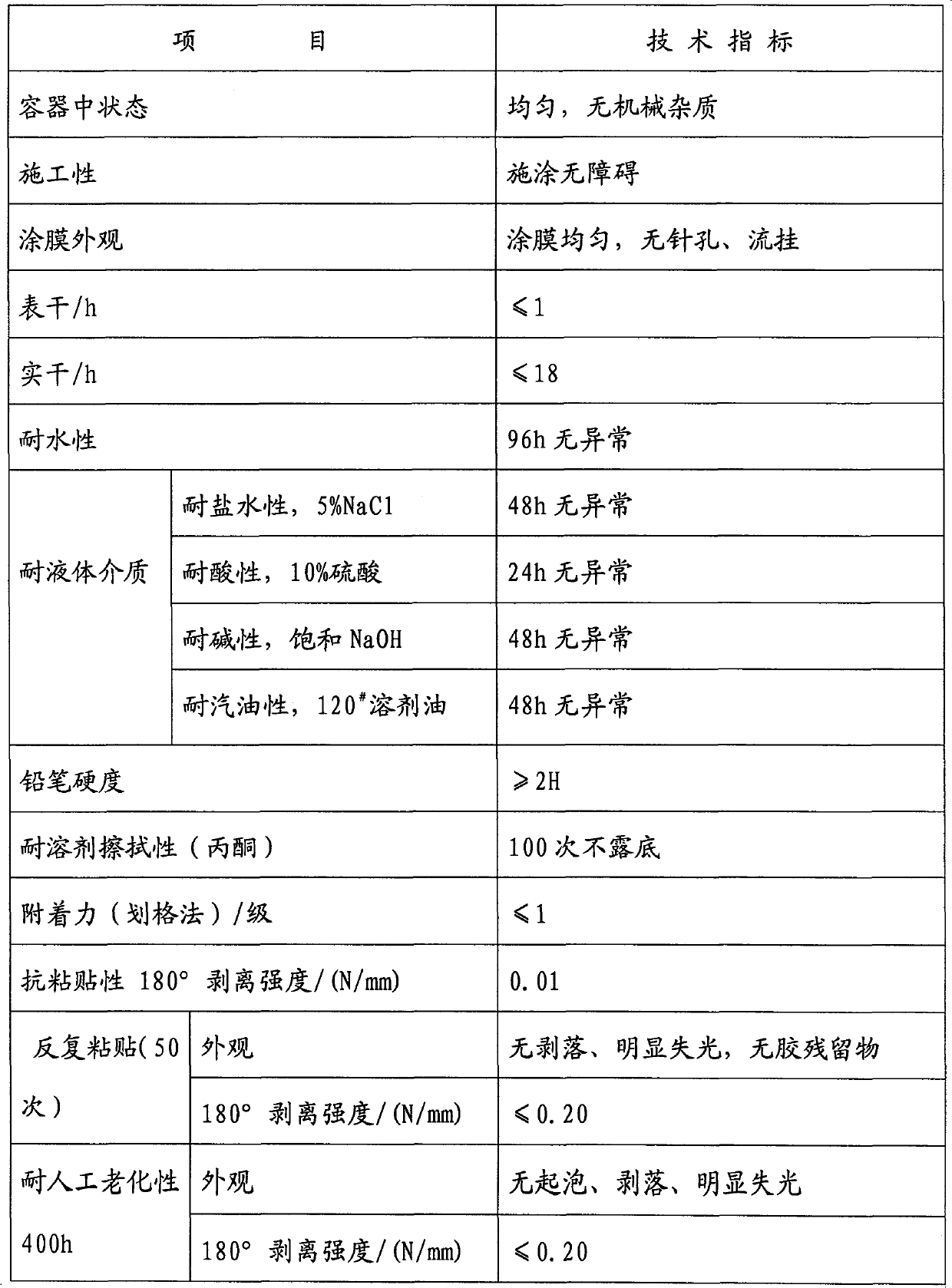

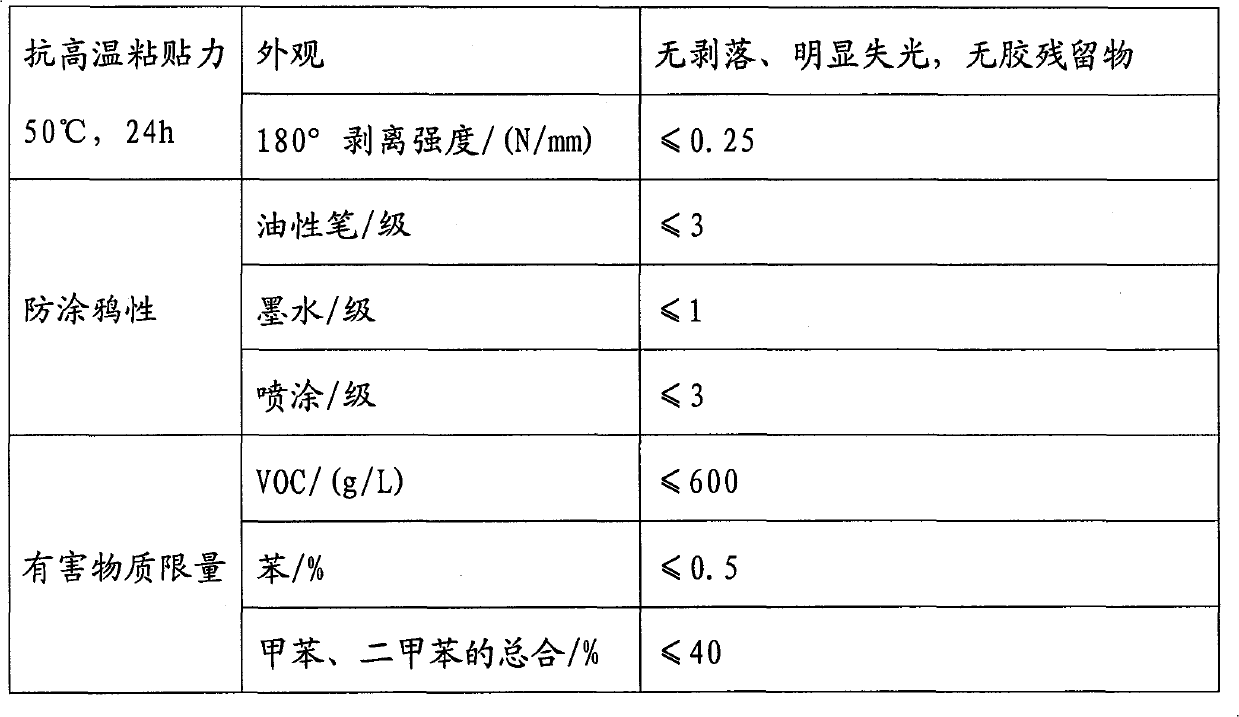

Oil-based anti-graffiti adhesion resistant paint and preparation method thereof

ActiveCN101585995AHigh hardnessImprove self-cleaningPolyurea/polyurethane coatingsAcrylic resinPolydimethyl siloxane

The invention discloses oil-based anti-graffiti adhesion resistant paint and a preparation method thereof, and belongs to paint and a preparation method thereof. Components A of the paint comprise hydroxy acrylic resin, fluorocarbon resin, modified polydimethyl siloxane resin, polyacrylate modified organic silicon resin, smooth flow agent, flatting agent, antifoaming agent, drier, dibutyl tin laurate, butyl acetate and dimethyl benzene; components B comprise hexamethylene diisocyanate, butyl acetate and ethylene glycol monoethyl ether acetate; and the mixture ratio of the components A to the components B is 3:1. The invention also discloses the preparation method thereof. The paint has the advantages of good anti-graffiti adhesion resistant function, super-strong scrubbing resistance, easy cleaning, and quick and convenient construction, has limited harmful substances, and achieves national requirement.

Owner:LANZHOU XUNMEI PAINT IND TECH

Halogen-free low temperature solidified silver paste and preparation method thereof

InactiveCN101950596AReduce pollutionSuitable process conditionsNon-conductive material with dispersed conductive materialCable/conductor manufactureLow temperature curingEthylene glycol monoethyl ether acetate

The invention provides a halogen-free low temperature solidified silver paste, which comprises the following raw materials in percentage by mass: 40 to 50 percent of conductive powder, 37 to 46 percent of solvents, 8 to 20 percent of high polymer resin and 1 to 3 percent of additives, wherein the conductive powder is a mixture of flake silver powder and silver coated nickel powder; the solvent is one or more of DBE, diethylene glycol monoethyl ether acetate, propylene glycol methyl ether acetate and ethylene glycol monoethyl ether acetate; the high polymer resin is one or more of polyester resins and polyurethane resins; and the additives comprise one or more of coupling agents, thickening agents and leveling agents. In the halogen-free low temperature solidified silver paste of the invention, the conductive powder is successfully used for replacing silver powder, which not only can reduce the cost, but also satisfies European safety standards, and reduces environment pollution.

Owner:IRICO

Two-component water-based hydroxyl acrylic coating

InactiveCN105368287AImprove adhesionStrong adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedAcrylic resin

The invention discloses a two-component water-based hydroxyl acrylic coating composed of a component A and a component B, wherein the weight ratio of the component A to the component B is 1 to (1-3). The component A comprises the raw materials in parts by weight: 40-80 parts of modified hydroxyl acrylic resin, 5-20 parts of water-based hydroxyl fluorosilicone acrylic resin, 5-15 parts of a water-based nano alumina dispersion body, 5-10 parts of a water-based nano silica dispersion body, 2-6 parts of ethylene glycol monoethyl ether acetate, 1-3 parts of a levelling agent BYK306, 0.2-0.8 part of a catalyst dibutyltin dilaurate, and 1-5 parts of xylene. The component B comprises the raw materials in parts by weight: 10-20 parts of a hexamethylene diisocyanate trimer, 1-5 parts of HDI biuret, and 20-30 parts of a diluent. The two-component water-based hydroxyl acrylic coating has good water resistance and excellent corrosion resistance.

Owner:ANHUI JINDUN PAINT

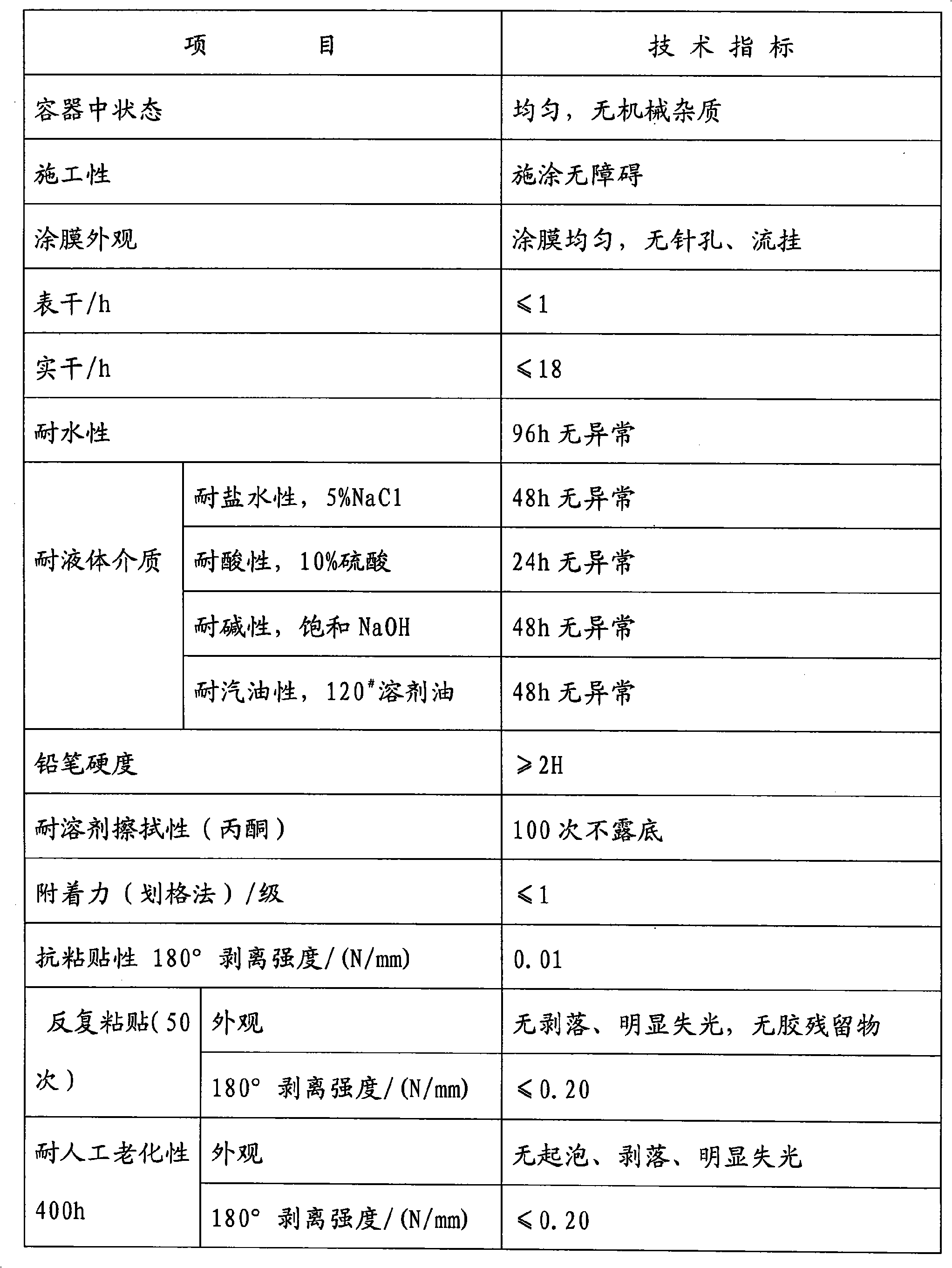

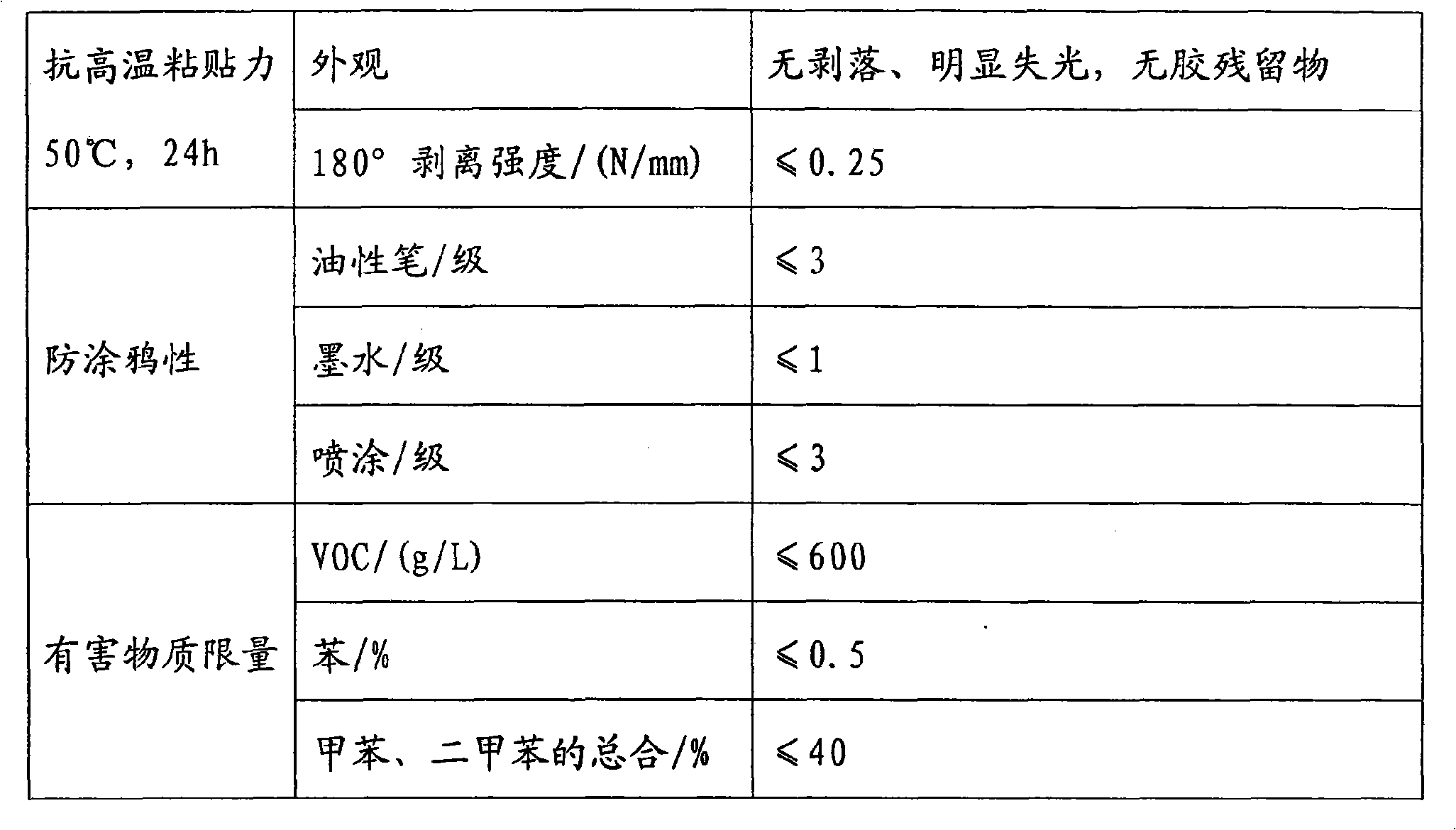

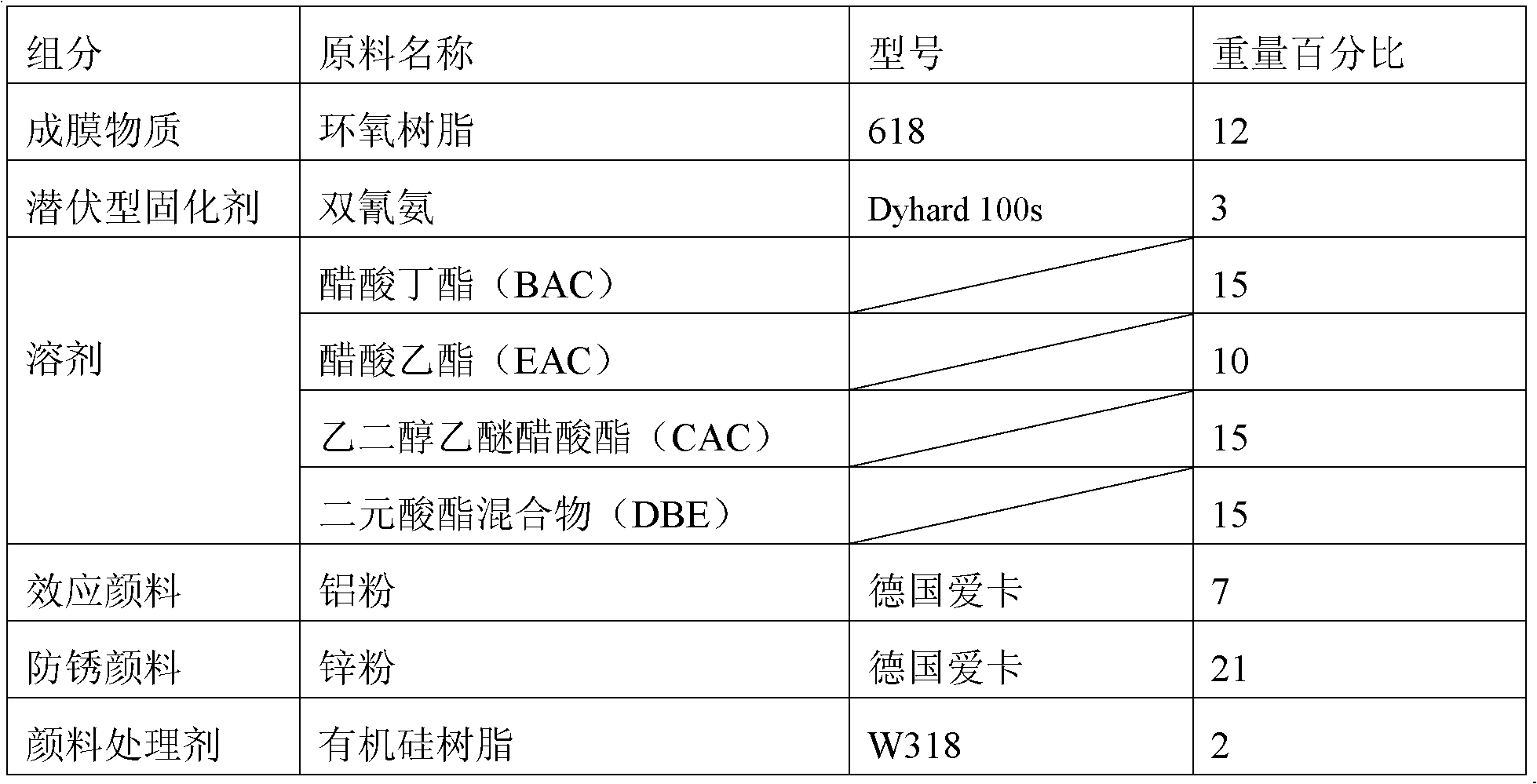

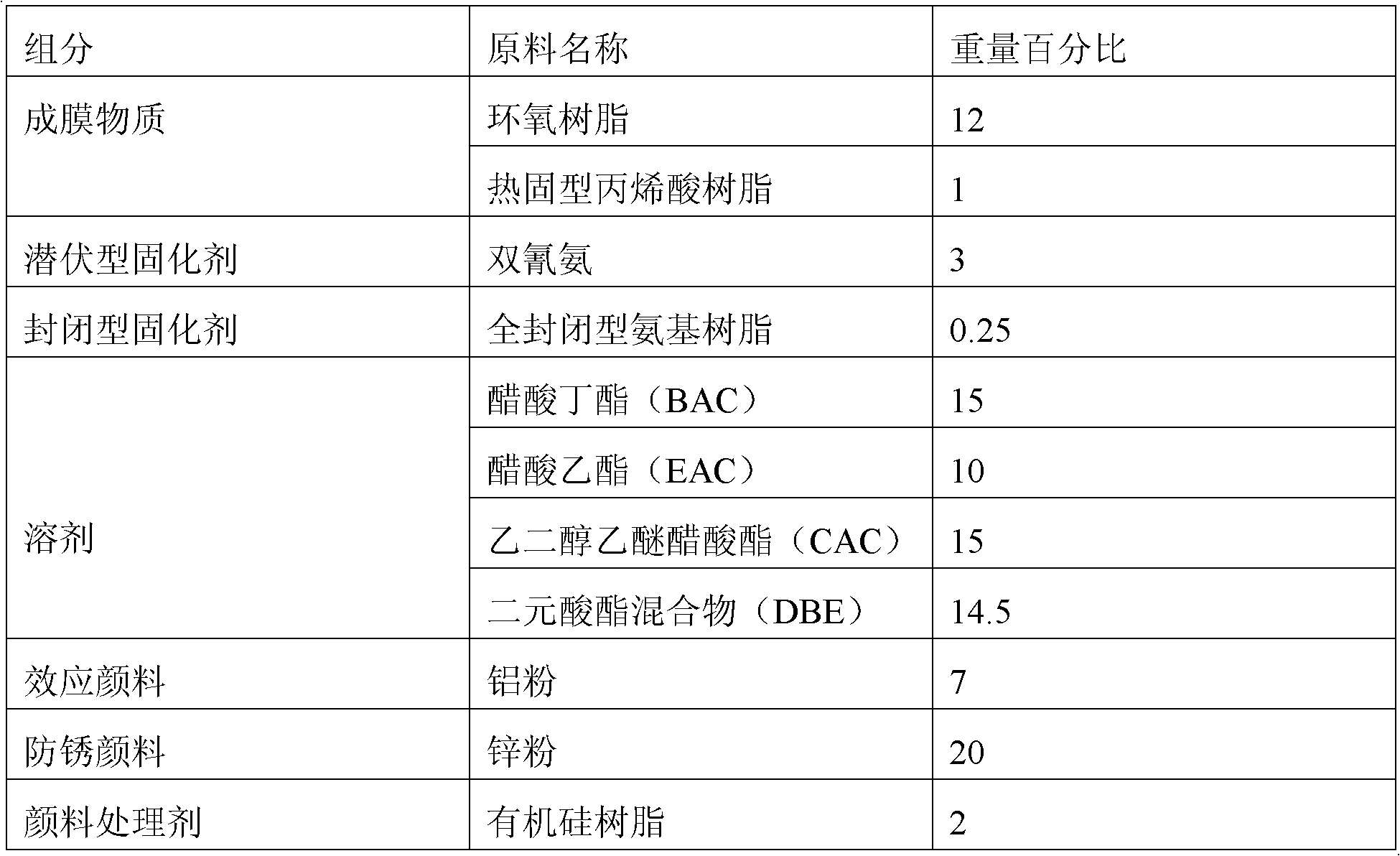

Anticorrosive coating and preparation method thereof

InactiveCN102372992AComply with ROHS requirementsBalanced Corrosion ResistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyEthyl ester

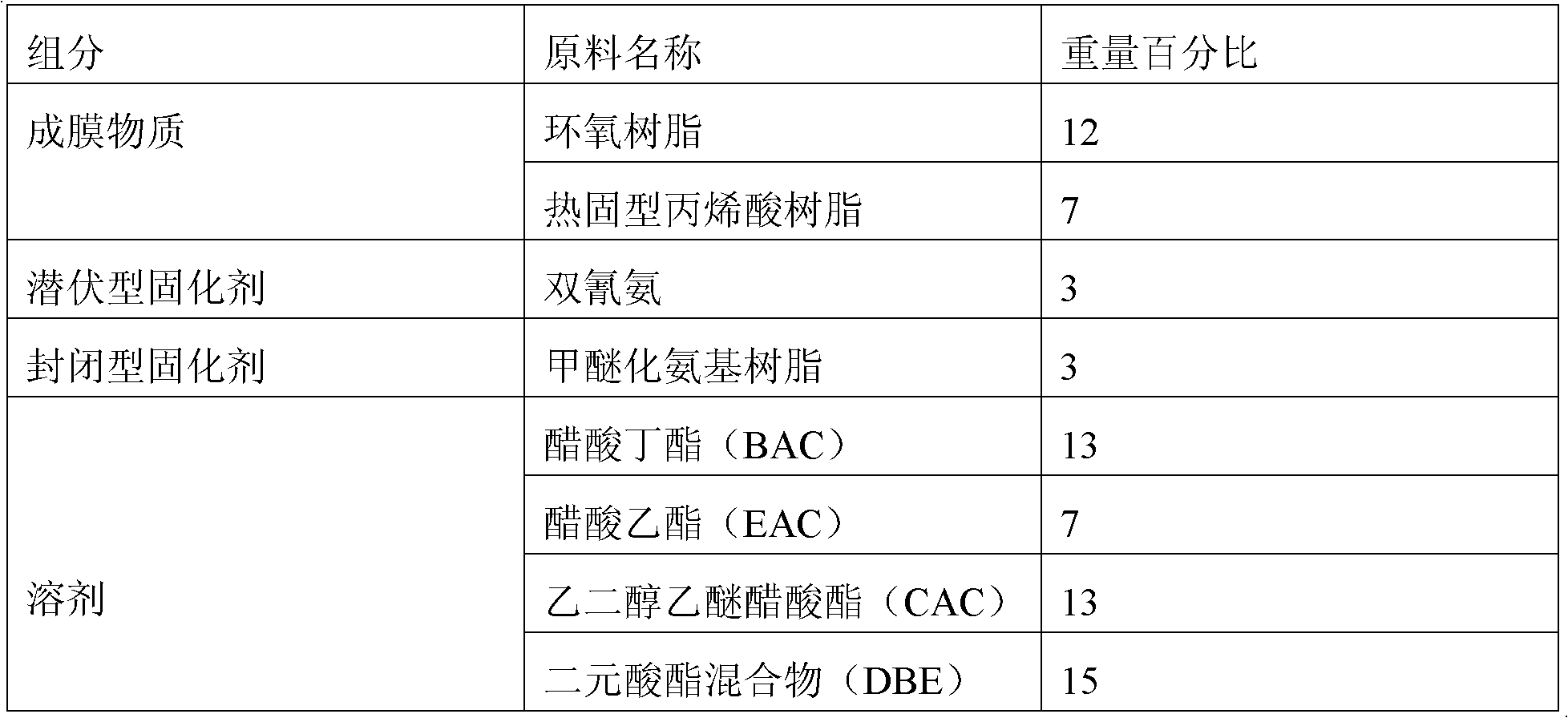

The invention discloses an anticorrosive coating and a preparation method thereof. The anticorrosive coating comprises a film forming substance, a curing agent, a solvent, pigments and a pigment treating agent, wherein, the film forming substance is epoxy resin, the curing agent is a latent curing agent, the solvent contains butyl acetate, acetic ester, ethylene glycol monoethyl ether acetate anda dibasic acid ester mixture, the pigments comprise effect pigments and antirust pigments, and the pigment treating agent is organic silicone resin; the weight percentage of the above-mentioned raw materials is as follows: epoxy resin 12 to 18, the latent curing agent 2 to 3, butyl acetate 10 to 15, acetic ester 5 to 10, ethylene glycol monoethyl ether acetate 10 to 15, the dibasic acid ester mixture 8 to 15, the effect pigments 5.25 to 7, the antirust pigment 15.75 to 21 and organic silicone resin 2 to 5. The anticorrosive coating provided in the invention does not contain heavy metals, being in accordance with ROHS requirements of European Union, and is a genuine environment-friendly and green anticorrosive coating.

Owner:马敏

Catechinic acid fiber blended deodorization flame-retardant woven fabric and manufacturing method thereof

ActiveCN104726994AVersatileImprove technical indicatorsFlame-proof filament manufactureMelt spinning methodsFiberPolyethylene glycol

The invention discloses catechinic acid fiber blended deodorization flame-retardant woven fabric. Raw materials of needed warp and needed weft for weaving comprise, by weight, 29 to 35 parts of syndiotactic polypropylene, 18 to 23 parts of polylactic acid, 8 to 12 parts of polyhydroxybutyrate, 3 to 5 parts of montmorillonoid, 0.02 to 0.05 part of canthaxanthin, 0.4 to 0.8 part of diprophylline, 0.5 to 0.9 part of calcium chloride, 23 to 28 parts of catechinic acid fibers, 25 to 30 parts of reed fibers, 18 to 24 parts of flame-retardant fibers, 17 to 23 parts of Lenzing modal fibers, 19 to 27 parts of zein fibers, 7 to 9 parts of oleic acid polyethylene glycol ester, 10 to 14 parts of ethylene glycol monoethyl ether acetate, 3 to 4 parts of peppermint, 2 to 5 parts of isatis roots, 1 to 3 parts of rheum officinale, 85 to 100 parts of 1-butyl-3-methylimidazolium acetate, 95 to 105 parts of 1-allyl-3-methylimidazolium chloride, 4 to 6 parts of auxiliaries and a proper amount of water. The fabric has the advantages of being resistant to odor, flames and abrasion, capable of absorbing sound and isolating heat and the like.

Owner:JIXI YUANDAO AGRI IND TECH

Waterproof coating

ActiveCN103740200AImprove waterproof performanceExtended service lifePolyurea/polyurethane coatingsEmulsionRosin

The invention discloses a waterproof coating, comprising the following raw materials in parts by weight: 15-40 parts of polyacrylic emulsion, 3-10 parts of polyurethane, 1-5 parts of an anti-settling agent, 20-40 parts of cement, 5-10 parts of GR composite titanium dioxide pigment, 0.5-5 parts of rosin modified phenolic resin, 2-4 parts of polyisocyanates, 2-4 parts of phenol, 1-2 parts of dimethylbenzene, 0.5-2 parts of silane coupling agent, 1-2 parts of ethylene glycol monoethyl ether acetate, 0.8-1.4 parts of a flatting agent and 0.5-1 part of a defoamer. The waterproof coating disclosed by the invention is excellent in waterproof property, not easy to mould and long in service life.

Owner:ANHUI JINDUN PAINT

Self-drying glass ink and preparation thereof

InactiveCN101412864AShould not be blockedReduce the frequency of cleaning the screenInksPolymer scienceEthylene glycol monoethyl ether acetate

The invention discloses a self-drying glass ink and a preparation method thereof. The self-drying glass ink comprises the following compositions in weight portion: 8 to 16 portions of gulf red nanometer paint, 15 to 20 portions of gulf red micron paint, 60 to 75 portions of modified splicing material, 0.5 to 1.5 portions of unsaturated carboxylate, 0.8 to 1.8 portions of modified polyacrylic ester, 0.8 to 3 portions of modified acrylic polymer, 0.5 to 1 portion of modified polydimethylsiloxane, 1 to 3 portions of modified microcrystalline polyethylene, 0.2 to 1 portion of 3-glycidol triethoxypropylsilane and 8 to 14 portions of ethylene glycol monoethyl ether acetate. The preparation method comprises the procedures of paint preparation, mixing and ink preparation. Compared with the prior art, the method adopts a nanometer level paint filler in order that the ink is uneasy to block meshes, reduces the times for cleaning a net, improves production efficiency, has good adhesive force and erosion resistance and high hardness, and does not need to roast.

Owner:芜湖力特尔涂料制造有限公司

High-wear-resistance automobile shaft component powder metallurgy material

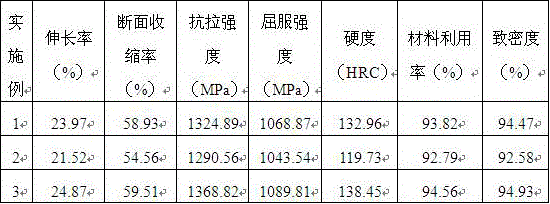

InactiveCN106270495AImprove performanceHigh densityTransportation and packagingMetal-working apparatusPolyvinyl chlorideTitanium carbide

The invention discloses a high-wear-resistance automobile shaft component powder metallurgy material. The high-wear-resistance automobile shaft component powder metallurgy material comprises the following raw materials: iron powder, chromium powder, molybdenum powder, copper powder, nickel powder, lead oxide powder, yttrium powder, titanium carbide powder, tantalum carbide powder, tin powder, zinc oxide powder, alumina powder, graphene powder, tetramethylolmethane, stearic acid, polyvinyl chloride fiber, basalt fibers, ethylene glycol monoethyl ether acetate, hypromellose, ethylene bisstearamide, chlorinated paraffin, glycidoxypropyl trimethoxysilane, silicon carbide, manganous sulphide, alcohol acid resin, an inhibitor, a binding agent, a reinforcing agent, a cutting agent, a lubricant, a cross-linking agent, a dispersant and a regulator. By the specific ingredient proportion, the high-wear-resistance automobile shaft component powder metallurgy material is uniform in integral density, high in compactness, high in extend rate and percentage reduction of area, good in wear resistance, strength and hardness and high in material utilization rate, and is suitable for quickly producing the high-performance automobile shaft component powder metallurgy material on a large scale.

Owner:GUANGXI NANNING ZHICUI SCI TECH CONSULTATION CO LTD

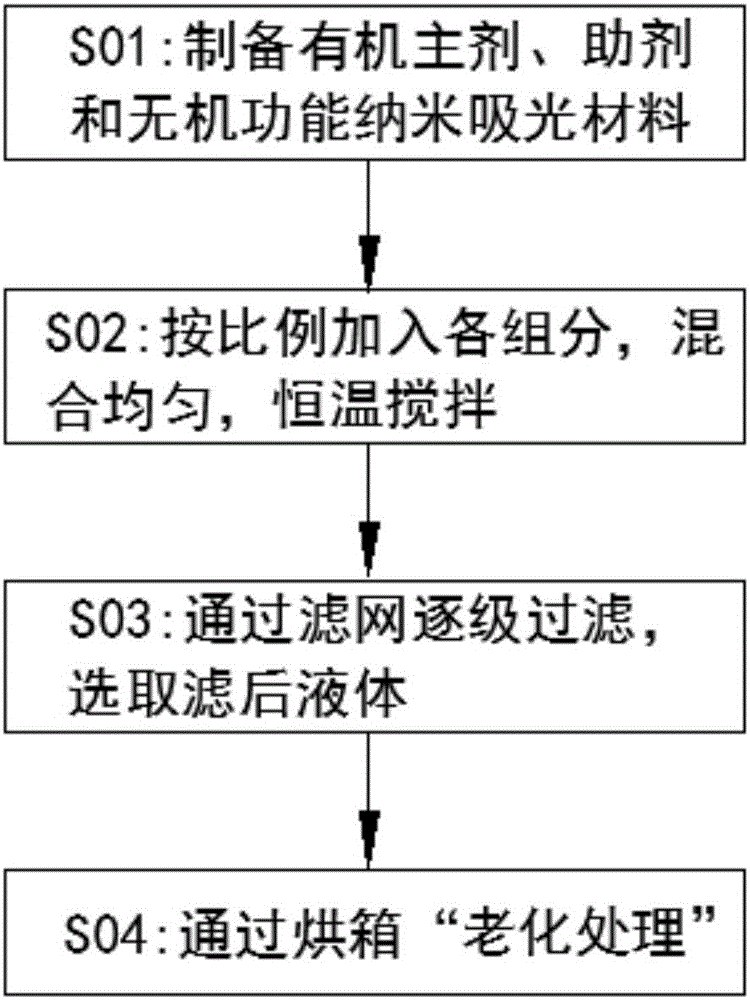

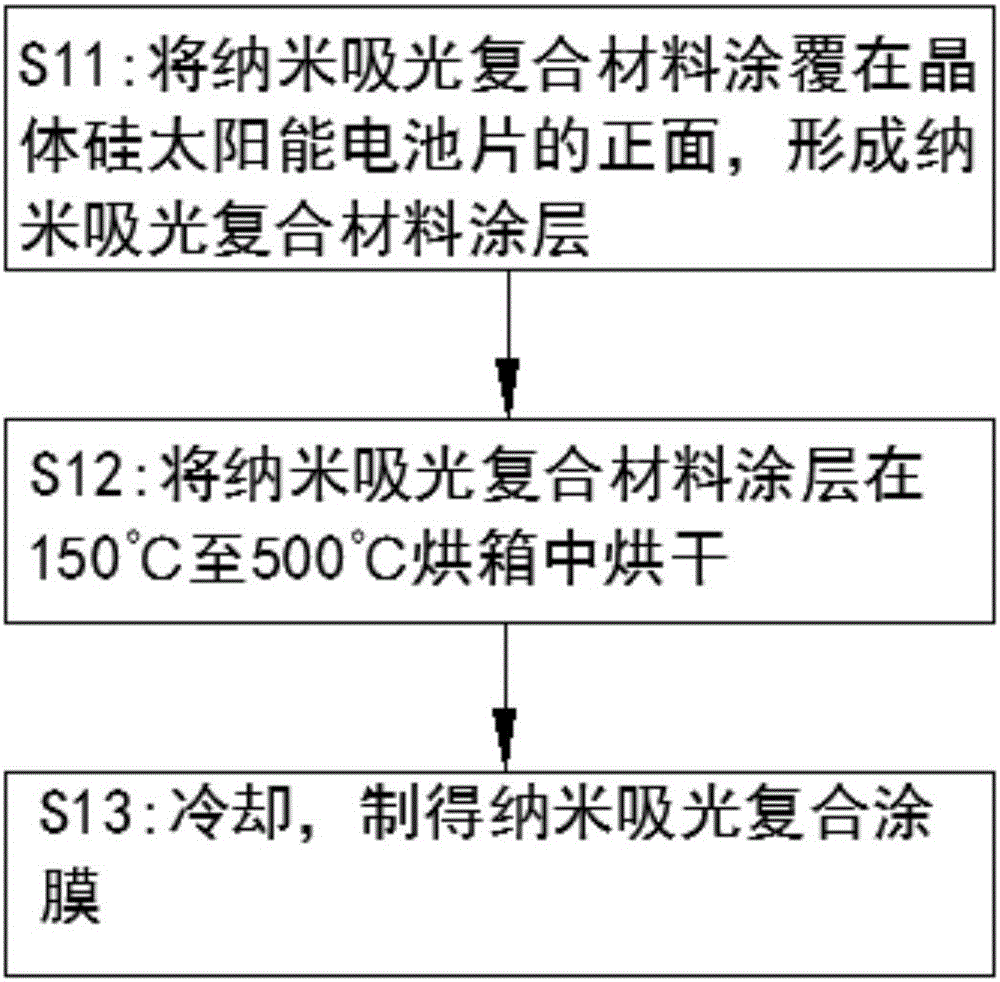

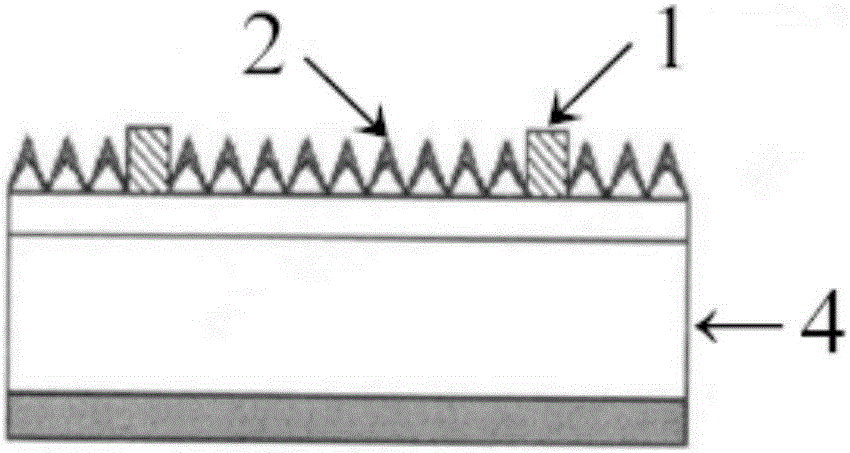

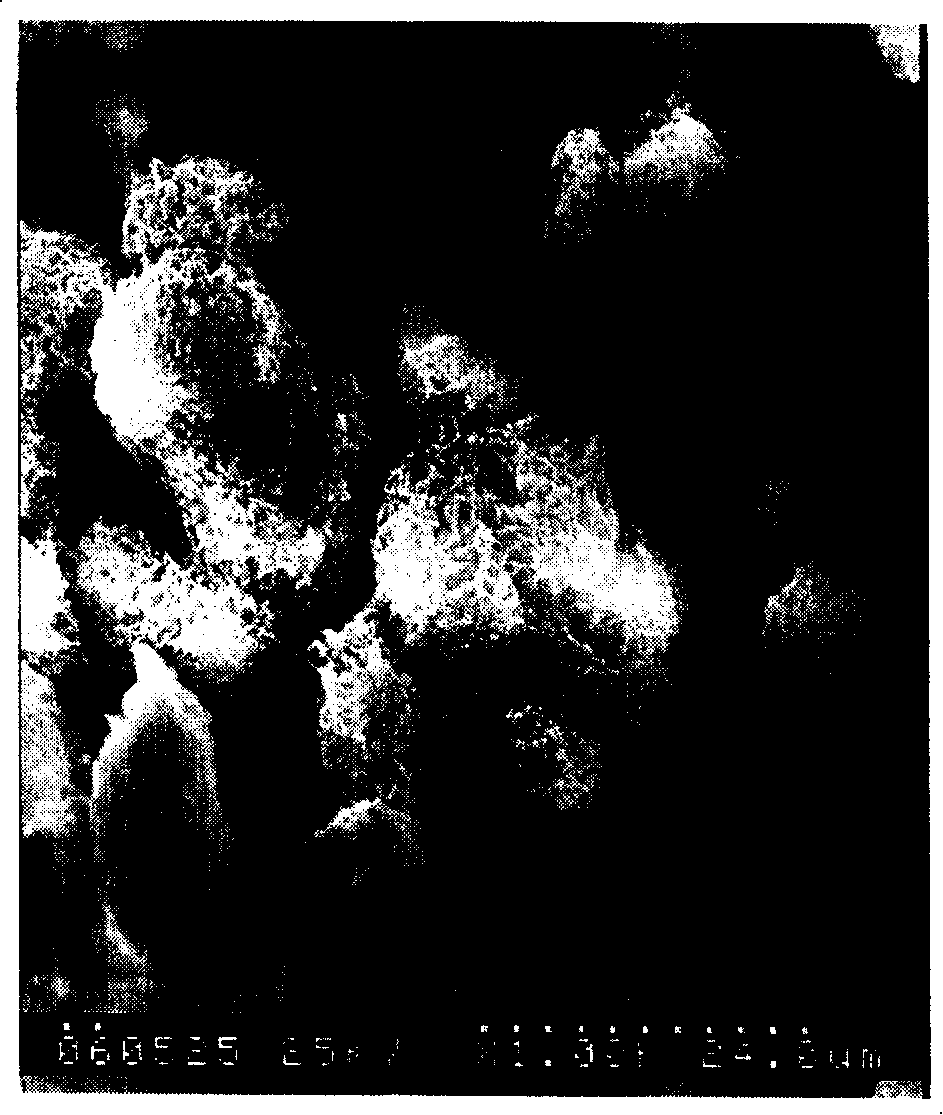

Nano light absorption composite material and preparation method thereof, and coated film preparation method

InactiveCN106653875AAdd refraction pathIncrease the absorption areaPhotovoltaic energy generationSemiconductor devicesDiethylene glycol monobutyl etherIndium

The invention discloses a nano light absorption composite material and a preparation method thereof, and a coated film preparation method. The nano light absorption composite material comprises an organic main agent, an auxiliary agent and an inorganic functional nano material, wherein the organic main agent is selected from at least one of ethylene glycol, diethylene glycol monobutyl ether, diethylene glycol dibutyl ether, ethylene glycol monoethyl ether acetate, n-butyl acetate, terpilenol, n-butanol and methyl isobutyl ketone; the auxiliary agent includes at least one of dispersant, thickener, flatting agent and defoaming agent; and the inorganic functional nano material is selected from at least one of zinc oxide, zinc sulfide, indium oxide, titanium dioxide, MxO, gallium compounds, cadmium telluride, calcium titanate, perovskite, graphene and nano precious metal. According to the nano light absorption composite material disclosed by the invention, a multilayer efficient antireflection branched structure is constructed on a surface of a textured antireflection layer of a crystalline silicon solar cell piece, so that a solar cell has excellent overall properties such as high incident light absorption, improved short circuit current, good electrical property and the like.

Owner:ENVIRONMENTAL NATURAL CHEM JIANGSU

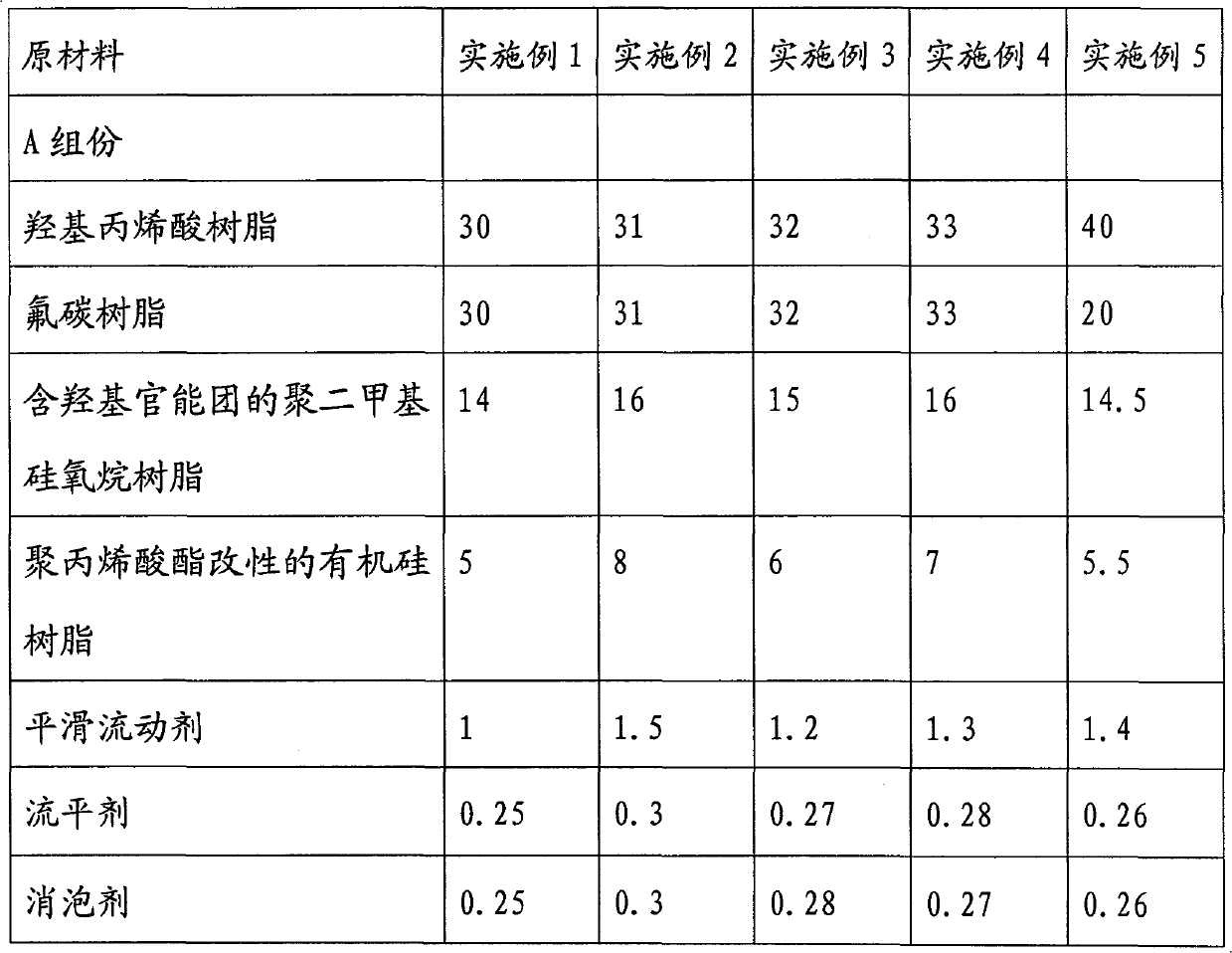

Oil-based anti-graffiti adhesion resistant paint and preparation method thereof

ActiveCN101585995BHigh hardnessImprove self-cleaningPolyurea/polyurethane coatingsAcrylic resinPolydimethyl siloxane

The invention discloses oil-based anti-graffiti adhesion resistant paint and a preparation method thereof, and belongs to paint and a preparation method thereof. Components A of the paint comprise hydroxy acrylic resin, fluorocarbon resin, polydimethyl siloxane resin containing hydroxyl functional group, polyacrylate modified organic silicon resin, smooth flow agent, flatting agent, antifoaming agent, drier, dibutyl tin laurate, butyl acetate and dimethyl benzene; components B comprise hexamethylene diisocyanate, butyl acetate and ethylene glycol monoethyl ether acetate; and the mixture ratio of the components A to the components B is 3:1. The invention also discloses the preparation method thereof. The paint has the advantages of good anti-graffiti adhesion resistant function, super-strong scrubbing resistance, easycleaning, and quick and convenient construction, has limited harmful substances, and achieves national requirement.

Owner:LANZHOU XUNMEI PAINT IND TECH

Waterborne polyurethane waterproof coating and production process thereof

InactiveCN104910781AGood weather resistanceImprove waterproof performancePolyurea/polyurethane coatingsEnvironmental resistancePropanoic acid

The invention discloses waterborne polyurethane waterproof coating and a production process thereof. The waterborne polyurethane waterproof coating comprises the following components in parts by weight: 25 to 35 parts of waterborne polyurethane resin, 10 to 20 parts of ethylene glycol monoethyl ether acetate, 1 to 10 parts of poly-dihydric alcohol, 2 to 8 parts of diglycol, 3 to 7 parts of dihydroxyl propionic acid, 4 to 9 parts of nano silica, 1 to 5 parts of tributyl phosphate, 5 to 15 parts of nanofiller, 2 to 6 parts of a flatting agent, 3 to 8 parts of a defoaming agent, 4 to 12 parts of a film-forming additive and 30 to 40 parts of deionized water. The waterborne polyurethane waterproof coating prepared by the method does not use an organic solvent, avoids environmental pollution, is environmentally friendly, has excellent weather resistance and waterproof effect, has high-glossiness coating and high ageing resistance, and is applicable in the fields of decoration and renovation of inner walls of kindergartens, houses, hotels and the like.

Owner:田福东

Antifreezing cooling liquid

InactiveCN104087258AGood storage stabilityCorrosion has a good inhibitory effectHeat-exchange elementsCalcium silicateDibutyl sebacate

The invention discloses an antifreezing cooling liquid which is composed of the following raw materials in parts by weight: 2-3 parts of ethylene glycol monoethyl ether acetate, 1-2 parts of 1,2-propanediol, 2-4 parts of polyethylene glycol, 2-3 parts of acrylic acid, 3-5 parts of ethylene glycol, 2-3 parts of azelaic acid, 3-4 parts of octanedioic acid, 4-5 parts of dibutyl sebacate, 2-4 parts of adipic acid, 3-4 parts of boric acid, 4-5 parts of sodium fluosilicate, 3-4 parts of calcium silicate, 3-5 parts of dimethicone, 2-5 parts of cinnamic acid, 4-6 parts of styrene, 2-4 parts of sorbitol and 100-120 parts of pure water. The antifreezing cooling liquid is good in storage stability and has a good inhibition effect on corrosion of aluminum and aluminum alloy.

Owner:司徒建辉

PCB conductive silver paste and preparing method thereof

InactiveCN104143377AReduce dosageUnique production processNon-conductive material with dispersed conductive materialCable/conductor manufacturePolyvinyl butyralCyclohexanone

PCB conductive silver paste is prepared by raw materials of, by weight, 5 to 10 parts of silver powder 10 nm to 20 nm in grain size, 30 to 40 parts of silver powder 1 micron to 10 micron in grain size, 15 to 20 parts of flaky silver coated copper powder containing 10% to 15% of silver, 0.2 to 0.3 part of a silane coupling agent KH-560, 8 to 12 parts of glass powder, 0.5 to 1 part of polyvinylpyrrolidone, 7 to 9 parts of polyvinyl butyral, 3 to 5 parts of ethyl cellulose, 6 to 8 parts of ethylene glycol, 2 to 4 parts of phthalic acid ester, 4 to 6 parts of isoamyl acetate, 5 to 7 parts of cyclohexanone, 2 to 4 parts of ethylene glycol monoethyl ether acetate and 1 to 2 parts of vitamin C. According to the PCB conductive silver paste, the use amount of the silver powder is reduced, the excellent conductive effect is achieved, after the glass powder is added, the properties such as moisture, surface smoothness and intermiscibility of the silver paste and bonding strength between the silver paste and a PCB are greatly improved, and defects such as bubbles and cracks are not likely to generate in the silver paste printing process.

Owner:永利电子铜陵有限公司

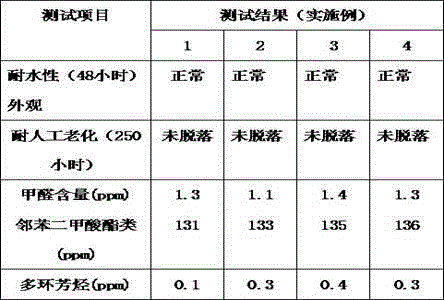

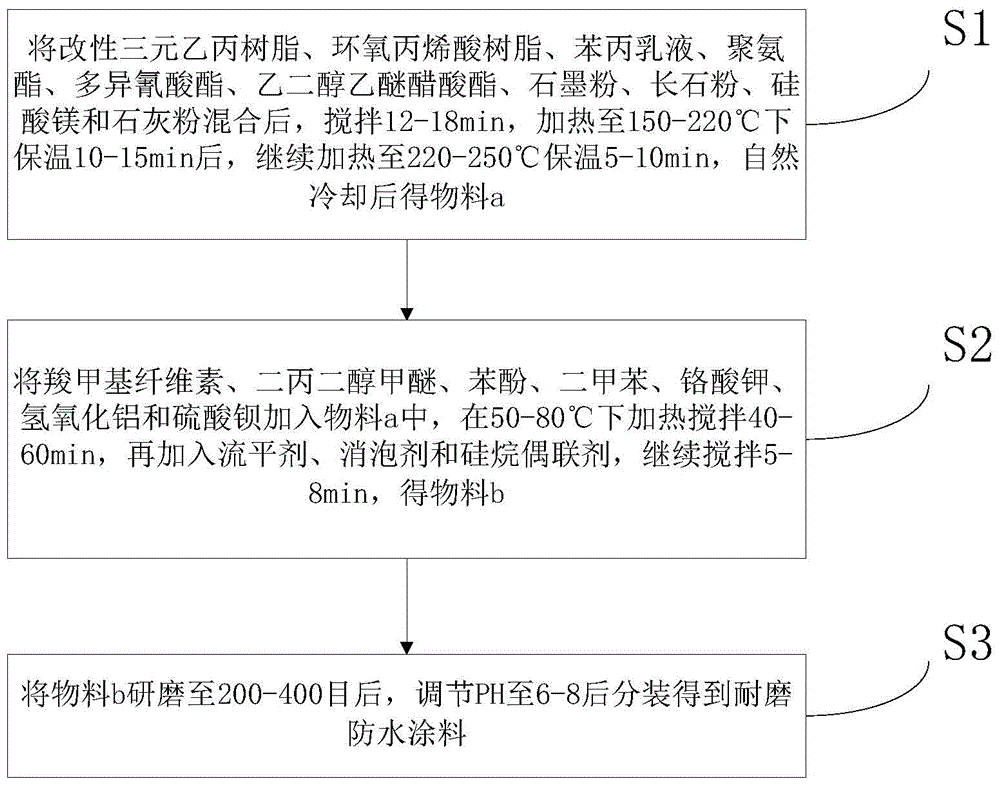

Abrasion-resistant waterproof coating for building outer wall and method for preparing the same

InactiveCN104946029AExtended service lifeLow costPolyurea/polyurethane coatingsAcrylic resinAluminium hydroxide

The invention discloses an abrasion-resistant waterproof coating for a building outer wall. The abrasion-resistant waterproof coating comprises, by weight parts, 60-80 parts of modified EPDM resin, 30-60 parts of epoxy acrylic resin, 20-40 parts of styrene-acrylic emulsion, 10-30 parts of polyurethane, 5-15 parts of polyisocyanate, 2-8 parts of ethylene glycol monoethyl ether acetate, 3-8 parts of graphite powder, 2-6 parts of feldspar powder, 1-5 parts of magnesium silicate, 2-6 parts of phenol, 3-5 parts of carboxymethyl cellulose, 2-5 parts of hydroxypropyl methylcellulose, 3-7 parts of dipropylene glycol methyl ether, 2-8 parts of phenol, 3-7 parts of xylene, 2-6 parts of potassium chromate, 1-3 parts of aluminum hydroxide, 2-4 parts of barium sulfate, 1-3 parts of flatting agent, 2-6 parts of defoamer and 1-5 parts of silane coupling agent. The invention further discloses a method for preparing the abrasion-resistant waterproof coating for the building outer wall. The abrasion-resistant waterproof coating for the building outer wall is excellent in abrasion resistance, good in waterproof performance, long in service life and low in cost.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

High temperature resistant anticorrosive paint

InactiveCN103173091AStrong resistance to salt waterGood weather resistanceAnti-corrosive paintsPolyamide coatingsEpoxyPolyamide

The invention discloses a high temperature resistant anticorrosive paint. The paint is characterized by being mainly prepared through stirring the following raw materials in parts by weight: 15-30 parts of organosilicon epoxy resin, 10-20 parts of polyamide resin, 3-8 parts of ethylene glycol monoethyl ether acetate, 20-30 parts of ceramic powder, 1-5 parts of ethylene glycol, 0-4 parts of nano zinc oxide, 1-6 parts of a silane coupling agent, 0.5-5 parts of a dispersing agent and 10-20 parts of kaolin. The prepared paint has the excellent performances such as strong salt water resistance, good weather resistance and good corrosion resistance.

Owner:JIANGSU JIFU NEW MATERIAL

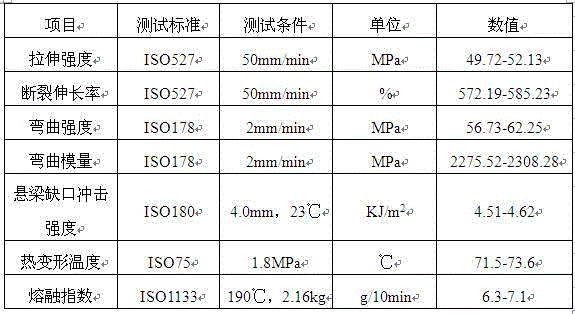

wood-plastic composite material for 3D (three-dimensional) printing

InactiveCN106479050AResolve affinitySolve temperature problemsAdditive manufacturing apparatusFiberPolyolefin

The invention discloses a wood-plastic composite material for 3D (three-dimensional) printing, and belongs to the technical field of preparation of the material for 3D printing; the wood-plastic composite material for 3D printing is prepared from, by weight, 96-135 parts of plant fiber powder, 11-4152 parts of polyolefin plastic powder, 38-54 parts of polylactic acid, 24-32 parts of potassium tripolyphosphate, 26-30 parts of ethylene glycol monoethyl ether acetate, 16-25 parts of specific compound agent and 8-14 parts of starch compound agent. The material prepared by the invention has very good toughness and impact intensity; the product printed by the 3D printing technology is high in quality, impact resistance and intensity, and also wide in market prospect.

Owner:蒙宇

Anticorrosive and antibacterial paint

InactiveCN102372967AEffectively removeImprove anti-corrosion performanceAntifouling/underwater paintsPaints with biocidesPolymer sciencePreservative

The invention discloses an anticorrosive and antibacterial paint, comprising the following ingredients: 52 weight portions of acrylic resin, 24 weight portions of nano titanium dioxide, 10 weight portions of nano copper powder, 16 weight portions of ethene diamine, 5 weight portions of silane coupling agent, 14 weight portions of ethylene glycol monoethyl ether acetate, 10 weight portions of cellulose acetate, 2 weight portions of preservative, 1 weight portions of mildew inhibitor, 5 weight portions of tannic acid, and 20-25 weight portions of Teflon. The invention has good anti-corrosive property, effective mildew removal and other excellent performances.

Owner:NANTONG TONGZHOU DISTRICT JINCHEN PAINT FACTORY

UV (ultraviolet) curing hardware coating and preparation method thereof

InactiveCN103525274AImprove wear resistanceImprove adhesionPolyester coatingsPolyesterMANGANESE ACETATE

The invention discloses a UV light curing hardware coating which comprises raw materials in parts by weight as follows: 45-50 parts of polyester acrylate, 20-25 parts of metacrylic acid ester, 10-14 parts of ethyl acetate, 3-4 parts of thiol polyorganosiloxane, 10-12 parts of dipentaerythritol hexaacrylate, 1-2 parts of a silane coupling agent KH560, 12-14 parts of tricresyl phosphate, 1-2 parts of methyl methacrylate, 3-5 parts of ethylene glycol monoethyl ether acetate, 1-2 parts of isoamyl butyrate, 4-6 parts of a photoinitiator 2959, 1-2 parts of manganese acetate and 4-5 parts of a dispersing auxiliary. According to the UV curing hardware coating, polyester acrylate and metacrylic acid ester are adopted as main materials, and plasticization and reinforcement substances such as tricresyl phosphate, manganese acetate and the like are added, so that the obtained coating has good cohesiveness, strong abrasive resistance, acid-base resistance, corrosion resistance and insulation; the UV coating is suitable for being used as the priming paint of hardware, zinc alloy, aluminum alloy and stainless steel and used as vacuum plating UV coating, the coating has durable performance, is superior to coatings for decorations of an automobile, a motorbike, a mobile phone and an electronic component in the market, and is strong in universality and high in curing speed; and the UV curing hardware coating has high production efficiency, saves cost and is simple in production process.

Owner:安徽蓝柯复合材料有限公司

Method for preparing polyvinylidene fluoride microporous filtering film

ActiveCN101234300AImprove performanceLow costSemi-permeable membranesChemical industryPorous membrane

The invention discloses a method for preparing the micro-porous filter membrane of polyvinylidene fluoride, which includes the following steps: 1) polymer homogeneous phase solution is evenly spreaded on the die to be formed by casting; cooling makes the polyvinylidene fluoride to crystallize and solidify into the membrane; the polymer homogeneous phase solution contains the polyvinylidene fluoride and the diluent; 2) The diluent in the extraction disks is washed and dried to prepare the micro-porous membrane of polyvinylidene fluoride; wherein, the diluent is ethylene glycol monoethyl ether acetate or / and diacetine. The micro-porous membrane of polyvinylidene fluoride prepared by the invention has evenly distributed pore diameter and various pore structure with good penetration, thus avoiding the formation of the loose pore structure in membrane; the micro-porous membrane of polyvinylidene fluoride prepared by the invention also has high porosity rate and the surface does not have the obvious densification cortex with high pure water flux which can be widely applied to the areas such as chemical industry, environmental protection, biochemical pharmacy, medical health and industry water purification treatment.

Owner:SHUANGJIE HIGH TECH DEV JILIN CITY

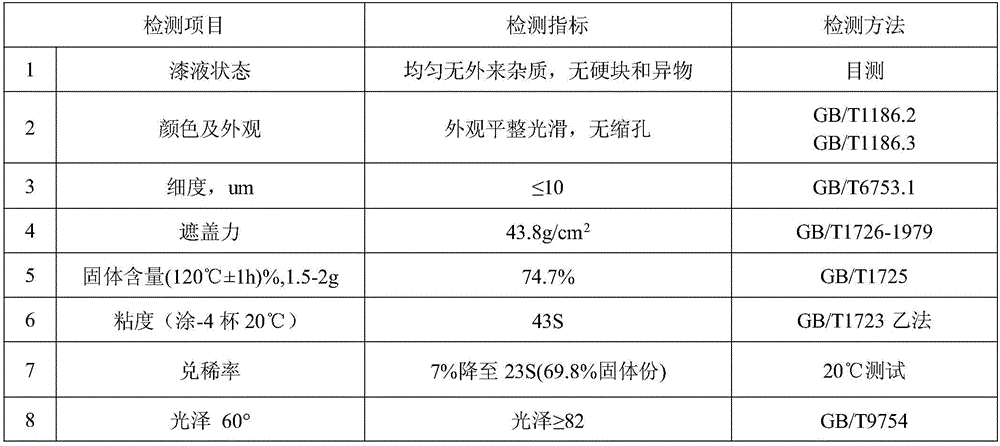

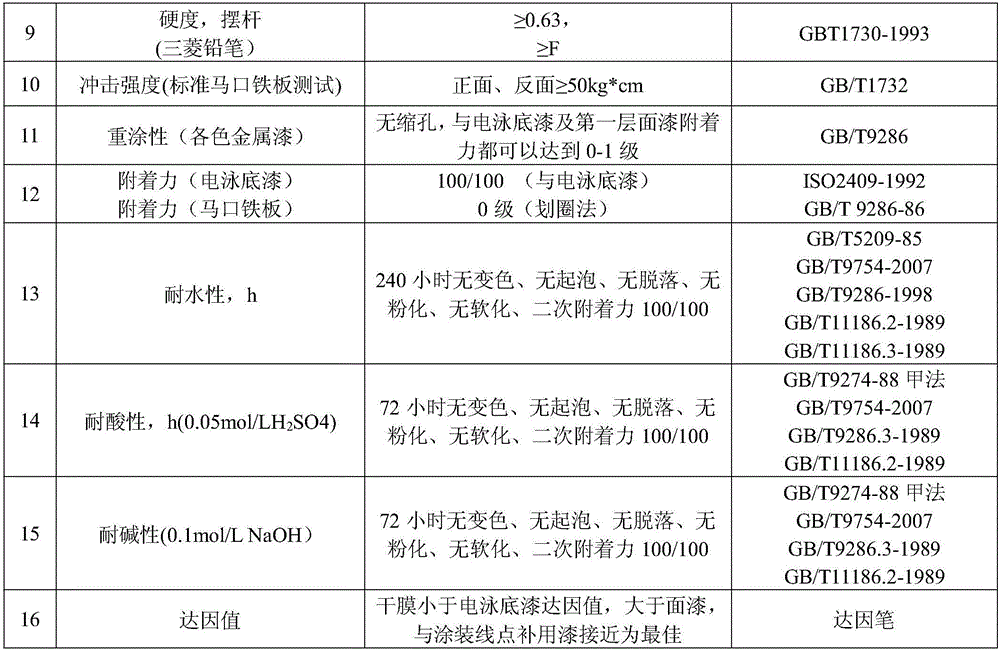

Automotive OEM (original equipment manufacturer) intermediate coat with high solid content and low viscosity and preparation method of intermediate coat

ActiveCN106118388ASmall molecular weightHigh solidsPolyester coatingsEthylene glycol monoethyl ether acetateGlass microsphere

The invention mainly relates to the field of coatings, in particular to an automotive OEM (original equipment manufacturer) intermediate coat with high solid content and low viscosity and a preparation method of the intermediate coat. The intermediate coat comprises raw materials in percentage by mass as follows: 25%-35% of polyester resin, 5%-12% of anti-sagging resin, 15%-25% of rutile titanium dioxide, 0-2% of hollow glass microspheres, 12%-18% of superfine precipitated barium sulfate, 1%-3% of a dispersing agent, 0.1%-0.3% of white carbon black, 0.1%-0.3% of an organosilicon leveling agent, 0.3%-0.6% of an acrylate leveling agent, 0.2%-0.5% of a surfactant, 0-2% of an anti-settling agent, 0-4% of cyclohexanone, 3%-5% of ethylene glycol monoethyl ether acetate, 0.05%-0.2% of carbon black, 20%-28% of butylated amino resin and 2%-4% of partial methylated amino resin. The intermediate coat is low in applicable viscosity, good in appearance, economical and environment-friendly and has high content of applicable solids.

Owner:山东时风(集团)有限责任公司

Composite fluorocarbon resin coating with excellent adhesion

The invention discloses composite fluorocarbon resin coating with excellent adhesion. The coating is prepared from the following raw materials in parts by weight: 15-35 parts of modified FEVE fluorocarbon resin, 20-60 parts of epoxy modified alkyd resin, 20-35 parts of epoxy resin, 1-3 parts of dicyandiamide, 1-2 parts of sodium dodecyl benzene sulfonate, 3-8 parts of carboxymethylcellulose, 1-5 parts of ethylene glycol monoethyl ether acetate, 5-15 parts of super fine calcium carbonate, 2-10 parts of magnesium silicate, 5-15 parts of kaolin, 2-8 parts of talc powder, 2-6 parts of graphene, 2-8 parts of amyl acetate, 4-10 parts of propylene glycol, 1-3 parts of a wetting agent, 1-3 parts of preservative, 2-10 parts of ethyl acetate, 2-7 parts of butylated amino resin, 2-6 parts of methylated amino resin and 40-80 parts of water. The composite fluorocarbon resin coating has good adhesion and excellent corrosion resistance.

Owner:合肥市易远新材料有限公司

Graphene modified epoxide anticorrosive coating and preparation method thereof

ActiveCN109777253AGood dispersionLow viscosityAnti-corrosive paintsEpoxy resin coatingsCyclohexanoneEpoxy

The invention relates to the field of epoxide anticorrosive coatings, specifically to a graphene modified epoxide anticorrosive coating. The graphene modified epoxide anticorrosive coating is preparedfrom a component A and a component B, wherein the component A mainly comprises epoxy resin, a pigment, a filler, an additive and graphene dispersing liquid; the component B is a curing agent; the mass ratio of the graphene dispersing liquid to the component A is (6-12):100; the mass ratio of the component A and the component B is (6-8):1; the graphene dispersing liquid is prepared by compositinggraphene, a mixing solvent and a dispersing agent B; the mixing solvent is a mixture of xylene, cyclohexanone, butanol, glycol ether and ethylene glycol monoethyl ether acetate. According to the graphene modified epoxide anticorrosive coating, the mixing solvent is adopted, so that the graphene can be uniformly dispersed into the coating; the prepared coating is high in stability, and high in anti-corrosive performance.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Hydrophobic coating for external wall of building and preparation method of hydrophobic coating

InactiveCN104893466AImprove hydrophobicityImprove acid resistanceAntifouling/underwater paintsPaints with biocidesMeth-Ethylic acid

The invention relates to a hydrophobic coating for the external wall of a building and a preparation method of the hydrophobic coating. The coating comprises the following components in parts by mass: 26-40 parts of acrylate emulsion, 12-22 parts of pure acrylic emulsion, 20-30 parts of kaolin powder, 3-10 parts of lithopone, 2-7 parts of kieselguhr, 1-5 parts of kyanite powder, 0.2-0.4 part of magnesium stearate, 0.1-0.3 part of tributyl phosphate, 0.1-0.26 part of polyoxyethylene propanolamine ether, 0.08-0.17 part of sodium carboxymethylcellulose, 0.12-0.33 part of isothiazolinone, 1-3.6 parts of propylene glycol, 0.1-0.4 part of 2-amino-2-methyl-1-propyl alcohol, 0.2-0.5 part of water repellent, 0.7-1.7 parts of propylene glycol methyl ether acetate, 0.2-0.5 part of ethylene glycol monoethyl ether acetate, 0.3-1 part of abietinol and 5-16 parts of water. The coating provided by the invention has good hydrophobic property and high acid resistance, aging resistance and sterilization and self-cleaning property.

Owner:SUZHOU DEXIANG DECORATION ENG

High-strength waterproof adhesive and preparation method thereof

InactiveCN103360961AHigh bonding strengthSimple ingredientsNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveEpoxyMorpholine

The invention discloses a high-strength waterproof adhesive. The high-strength waterproof adhesive is prepared from the following materials in parts by weight: 10-12 parts of E-44 epoxy resin, 3-4 parts of diethylenetriamine, 3-4 parts of polystyrene, 3-4 parts of coumarone, 2-3 parts of titanium dioxide, 3-4 parts of acrylic acid, 4-5 parts of ethylene glycol monoethyl ether acetate, 3-4 parts of butanediol, 2-3 parts of tert-butyl peroxybenzoate, 4-5 parts of attapulgite powder, 2-3 parts of silane coupling agent KH560, 1-2 parts of morpholine, 15-17 parts of acetone and 8-10 parts of ethyl acetate. The high-strength water-absorbing adhesive disclosed by the invention is simple in material, low in price, high in adhesion strength and long in service life.

Owner:滁州市鑫彩印务有限公司

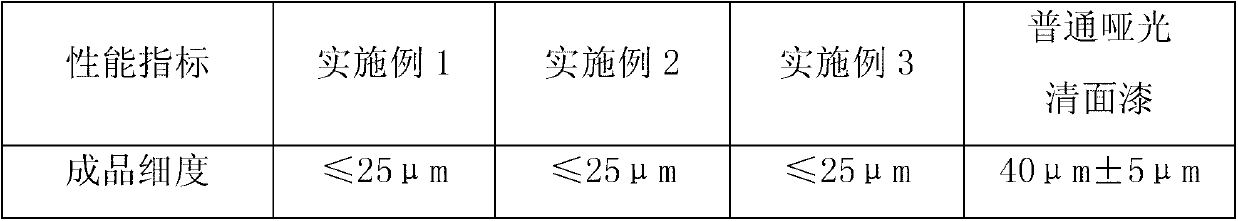

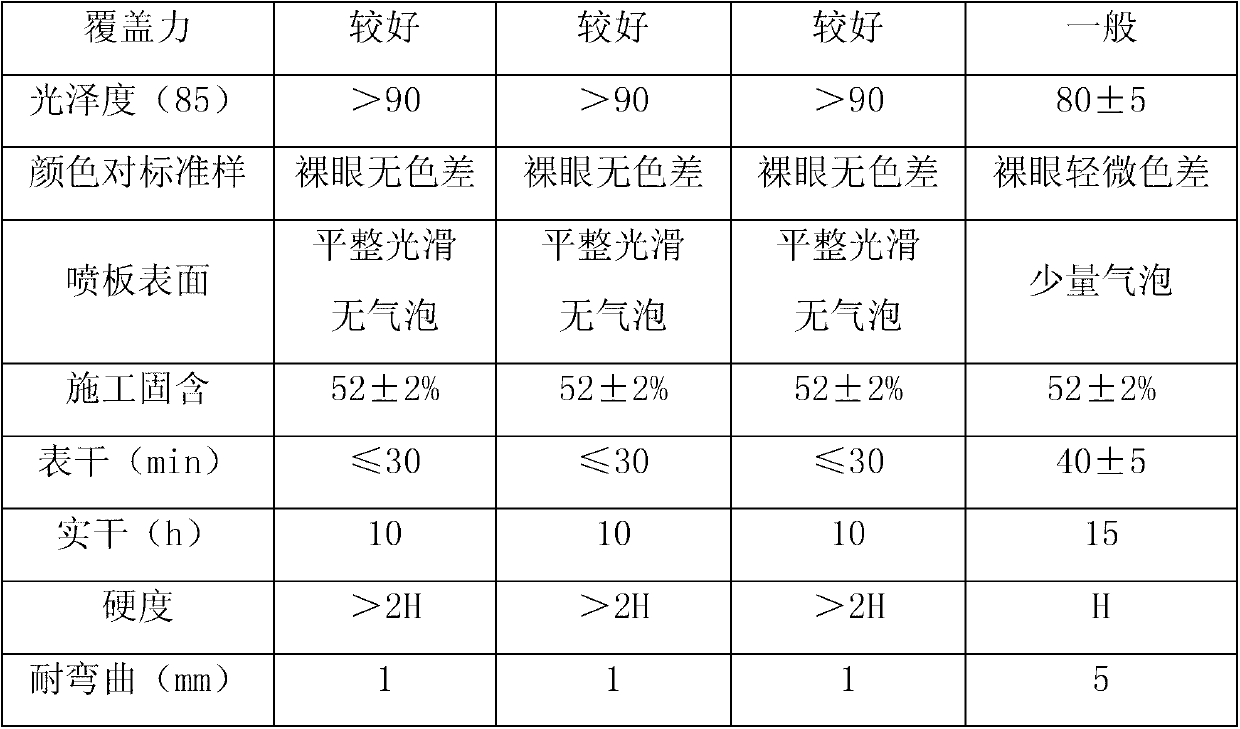

Low-gloss clear finishing coat and preparation method thereof

ActiveCN103102775AStrong scratch resistanceExtended service lifePolyester coatingsCyclohexanoneHardness

The invention discloses a low-gloss clear finishing coat. The low-gloss clear finishing coat comprises the following components in parts by weight: 71.5-72.5 parts of modified alkyd resin, 4.8-5.3 parts of dimethylbenzene, 4.6-5.0 parts of n-butyl acetate, 0.15-0.25 part of dispersing agent, 0.10-0.20 part of antifoaming agent, 3.8-4.2 parts of bentonite, 4.8-5.1 parts of extinction powder, 3.6-4.2 parts of nitro-cotton liquid, 1.8-2.4 parts of cyclohexanone, 0.28-0.40 part of flatting agent, 1.8-2.1 parts of ethylene glycol monoethyl ether acetate and 0.15-0.25 part of dryer. The hardness of the low-gloss clear finishing coat obtained by adopting the special ingredients and the preparation method is twice more than that of the common low-gloss clear finishing coat, the anti-scratching capacity is strong and the service life is greatly prolonged. Meanwhile, the other the other performances also completely satisfy the standards, and the hand feeling is good, and so the low-gloss clear finishing coat is applicable to the decorative field of the solid-wood furniture.

Owner:CHONGQING PINSHENG PAINT

Heat-resistant and chemical-resistant paint for mechanical equipment and preparation method of heat-resistant and chemical-resistant paint

ActiveCN104212318AExtended service lifeStrong practical valuePolyester coatingsAcrylic resinThermal insulation

The invention discloses a heat-resistant and chemical-resistant paint for mechanical equipment and a preparation method of the heat-resistant and chemical-resistant paint. Aiming at the defects existing in an existing paint for mechanical equipment, the heat-resistant and chemical-resistant paint is prepared from damping packing, soya alkyd resin, thermoplastic acrylic resin, ethylene glycol monoethyl ether acetate, a thermal insulation material, hydroxypropyl methyl cellulose, hydroxyethyl cellulose, a hyper-dispersant, a defoaming agent, a heat-resisting agent and a curing agent according to a certain preparation method. The heat-resistant and chemical-resistant paint for the mechanical equipment disclosed by the invention not only has relatively good anti-fouling property, alkaline resistance and aging and washing resistance, but also has strong heat-resistant and anti-corrosion performances and chemical corrosion resistance, the defects of a traditional paint for mechanical wear-resistant equipment are broken through, the service life of the mechanical equipment is prolonged, and the heat-resistant and chemical-resistant paint has strong practical value.

Owner:青岛武田新材料有限公司

Roll line solution for repairing surface coating of railway vehicle seamlessly and preparation method and application of roll line solution

The invention discloses a roll line solution for repairing a surface coating of a railway vehicle seamlessly and a preparation method and application of the roll line solution. The roll line solution is prepared from 55-75 parts by weight of mixed dibasic acid ester (PME), 20-40 parts of ethylene glycol monoethyl ether acetate (CAC), 0-10 parts of butyl acetate, 3-10 parts of mono-component acrylic resin, 0.2-0.6 part of defoaming agent and 0.4-0.8 part of flatting agent. The preparation method comprises the steps of: firstly, weighing all components in the terms of weight proportion; secondly, putting all the components in a container, and rapidly and uniformly stirring; and finally, standing for 8-15min. During the use, a local defect part of the surface coating of the railway vehicle is conventionally treated and subjected to paint repair, then the roll line solution is sprayed for the first time in a connector position of a new paint film coating and an old paint film coating and is sprayed for the second time after 50-70s, and after the paint films are actually dried, the seamless effect of consistent appearances of the new coating and the old coating can be achieved. The roll line solution can ensure that no seam exists on the appearances of the new coating and the old coating through visual inspection by once repairing the local defect, thereby being especially suitable for the requirement of integrally consistent appearances of high-performance railway vehicles.

Owner:CRRC YANGTZE CO LTD

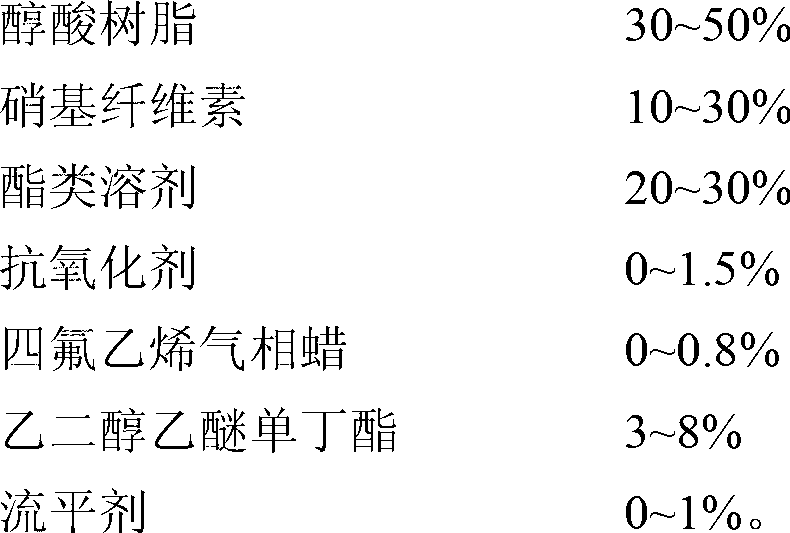

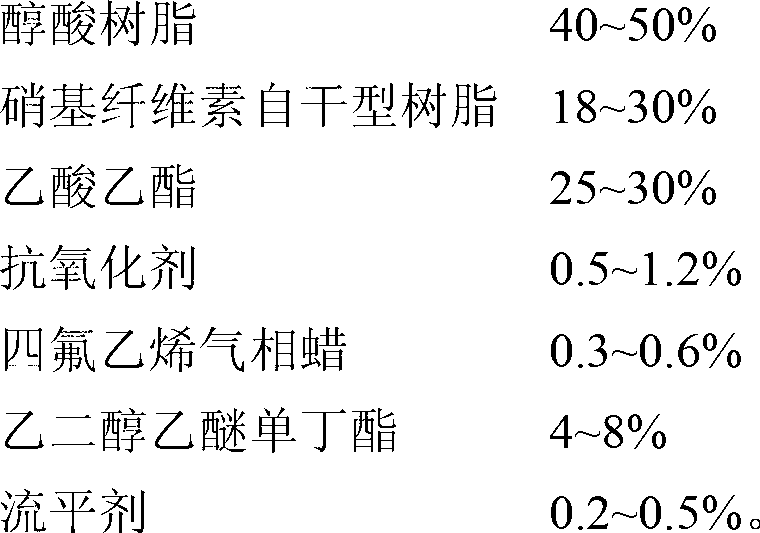

UV (ultraviolet) ink bridging agent and application thereof

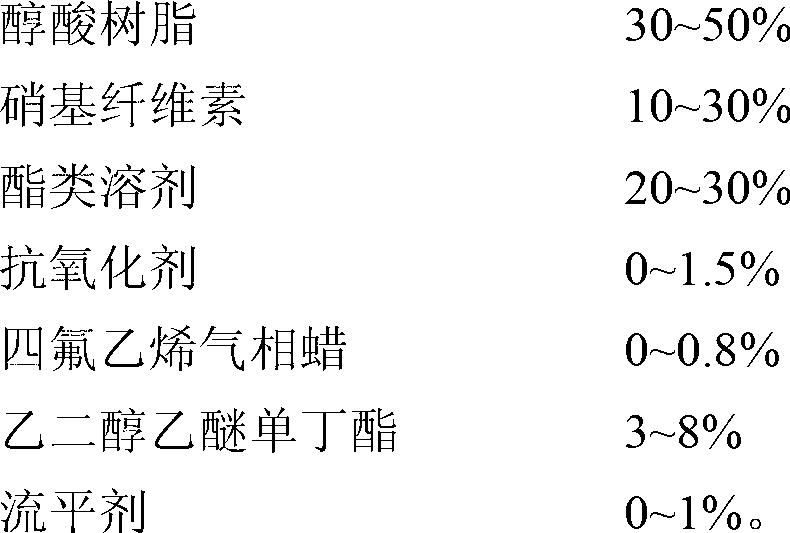

InactiveCN102936450AImprove adhesionNot easy to fall offInksPolyester coatingsDiethylene glycol monobutyl etherCellulose

The invention provides a UV (ultraviolet) ink bridging agent and application thereof. The bridging agent comprises resin, a curing agent and a solvent, wherein the resin comprises the following components in percentage by weight: 30-50% of alkyd resin, 10-30% of cellulose nitrate, 20-30% of ester solvent, 0-1.5% of antioxidant, 0-0.8% of tetrafluoroethylene gas-phase wax, 3-8% of diethylene glycol monobutyl ether and 0-1% of leveling agent; the curing agent comprises the following components in percentage by weight: 20-80% of low free TDI (toluene diisocyanate) curing agent raw material and 20-80% of ethyl acetate; and the solvent comprises the following components in percentage by weight: 70-90% of ethyl acetate, 8-20% of ethylene glycol monoethyl ether acetate and 1-10% of diethylene glycol monobutyl ether. The bridging agent provided by the invention is used for the UV ink printing of plates and can effectively enhance the adhesive force of ink on the plates.

Owner:广州酷漫居动漫科技有限公司

Preparation method of copper electronic paste for piezoelectric ceramics

ActiveCN105161221AReduce manufacturing costLow priceCable/conductor manufactureEthylene glycol monoethyl ether acetateButyl carbitol

The invention discloses a preparation method of copper electronic paste for piezoelectric ceramics. The method comprises steps of: preparing an organic carrier by using terpilenol, ethyl cellulose, dibutyl carbitol, ethylene glycol monoethyl ether acetate, polyether antifoaming agent, and silane coupling agent; mixing and dispersing copper powder, glass powder, thixotropic agent, and surfactant with the organic carrier so as to obtain the copper electronic paste for piezoelectric ceramics. The method is easy to operate and may achieve production without complex equipment. The copper powder is low in price so as to greatly reduce the production cost of the electronic paste. The prepared copper electronic paste is used for preparing piezoelectric ceramic material. Compared with a method for preparing a piezoelectric ceramic by using conventional silver paste, aluminum paste or the like, the method solves a problem of metal ionic migration and a defect of low adhesion strength and improves the vibration frequency and the conductive performance of the piezoelectric ceramic. The copper electronic paste can be sintered in the air and stored for a long time, and has excellent high-temperature stability performance and oxidation resistance.

Owner:西安创联光电新材料有限公司

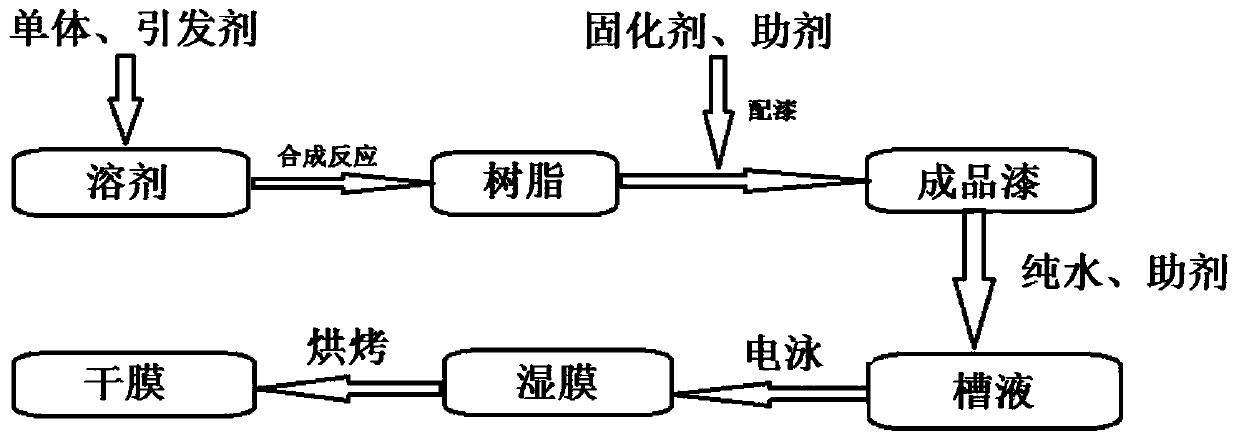

Cathode electrophoretic paint resin with high salt spray resistance and preparation method thereof

InactiveCN110117339AHigh resistance to salt sprayImprove salt spray resistancePaints for electrolytic applicationsPolymer science(Hydroxyethyl)methacrylate

Disclosed are a cathode electrophoretic paint resin with high salt spray resistance and a preparation method thereof. Monomers adopted for the resin comprise monomers of methyl methacrylate, styrene,hydroxyethyl methacrylate, 2-(dimethylamino)ethyl methacrylate, butyl acrylate and phosphate; an initiator comprises azodiisobutyronitrile; a solvent is one or a mixture of more of isopropanol, ethylene glycol monoethyl ether, ethylene glycol monobutyl ether, ethyl acetate, butyl acetate, ethylene glycol monoethyl ether acetate and n-butyl alcohol; a neutralizing agent comprises one of formic acid, acetic acid and lactic acid. The solvent is loaded in a reactor, the initiator and the solvent are added for stirring, and heating is conducted to 80-100 DEG C; a mixture of the monomers and the initiator is added dropwise 1-5 times for 2-4 hours, and after dropwise addition, heat preservation is conducted for 0.5-2.5 hours at 80-100 DEG C; the remaining initiator is added for supplementation twice, and after heat preservation continues for 0.5-2.5 hours, the electrophoretic paint resin is obtained. The cathode electrophoretic paint resin has high salt spray resistance, the salt spray resistance of a paint film of the electrophoretic paint is greatly improved, and the quality of a product processed by the electrophoretic paint is further improved.

Owner:SHENZHEN CHIBOOM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com