Nano light absorption composite material and preparation method thereof, and coated film preparation method

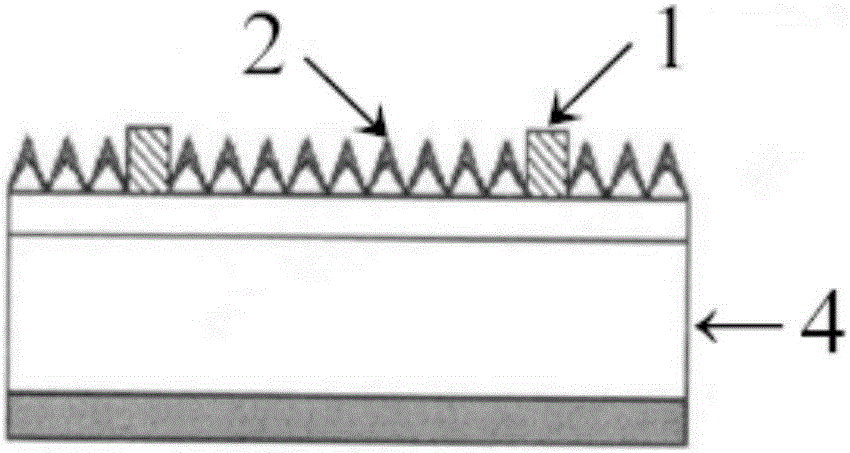

A composite material and nanotechnology, applied in the fields of photovoltaic power generation, electrical components, circuits, etc., can solve the problems of high light reflectivity, mechanical damage on the surface of silicon wafers, and less industrial use, etc., to increase the refraction path, increase the absorption area, reduce the The effect of reflection loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

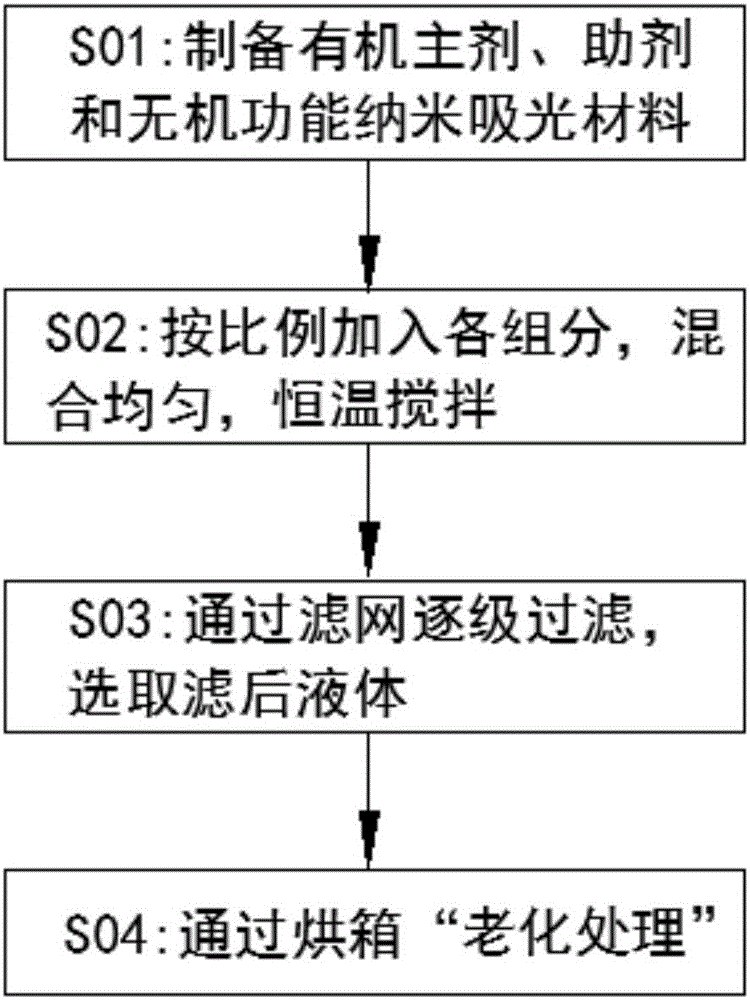

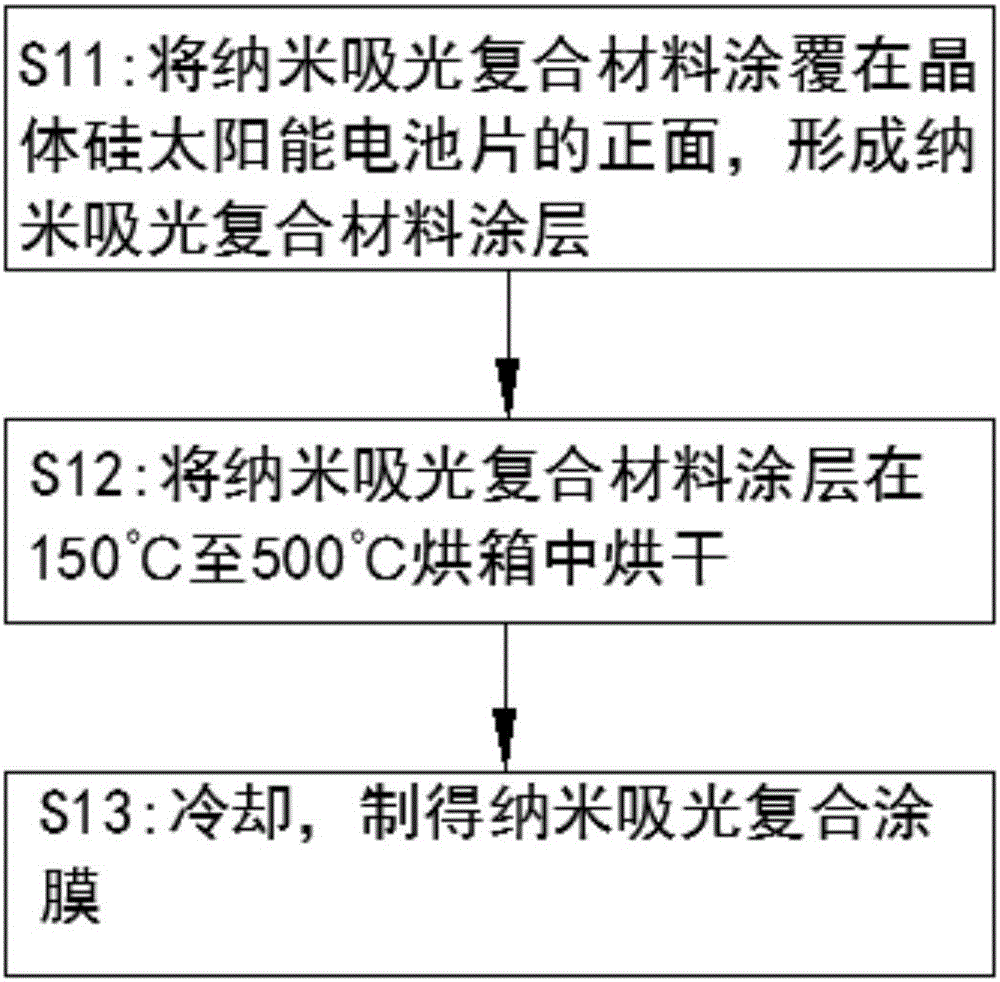

Method used

Image

Examples

Embodiment 1

[0063] In Example 1, the particle size of zinc oxide is 1-10 μm, the particle size of titanium dioxide is 1-5 μm, the particle size of calcium titanium oxide and perovskite is 0.1-5 μm, and the mass ratio of zinc oxide to titanium dioxide is It is 0.2 / 0.4--0.8 / 0.2.

Embodiment 2

[0064] In Example 2, the particle size of zinc oxide is 1-10 μm, the particle size of titanium dioxide is 1-5 μm, the particle size of zinc sulfide is 1-5 μm, and the particle size of gallium nitride and perovskite are both 0.1-5μm, the mass ratio of the sum of zinc oxide and zinc sulfide to titanium dioxide is 0.2 / 0.4--0.8 / 0.2, and the mass ratio of zinc oxide to zinc sulfide is 0.35 / 0.35-0.65 / 0.35.

Embodiment 3

[0065] In Example 3, the particle size of zinc oxide is 0.01-1 μm, the particle size of titanium dioxide is 5-10 μm, the particle size of magnesium oxide and cadmium telluride is 1-6 μm, and the particle size of perovskite is 0.1-1 μm, the mass ratio of the sum of magnesium oxide and zinc oxide to titanium dioxide is 0.3 / 0.7-0.7 / 0.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com